A kind of au@pt core-shell type ultramicro electrode and preparation method thereof

An ultra-micro electrode, core-shell technology, which is applied in the fields of electrochemical variables of materials, material analysis by electromagnetic means, instruments, etc., can solve the problems of high cost and long time, and achieve low cost, short time and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

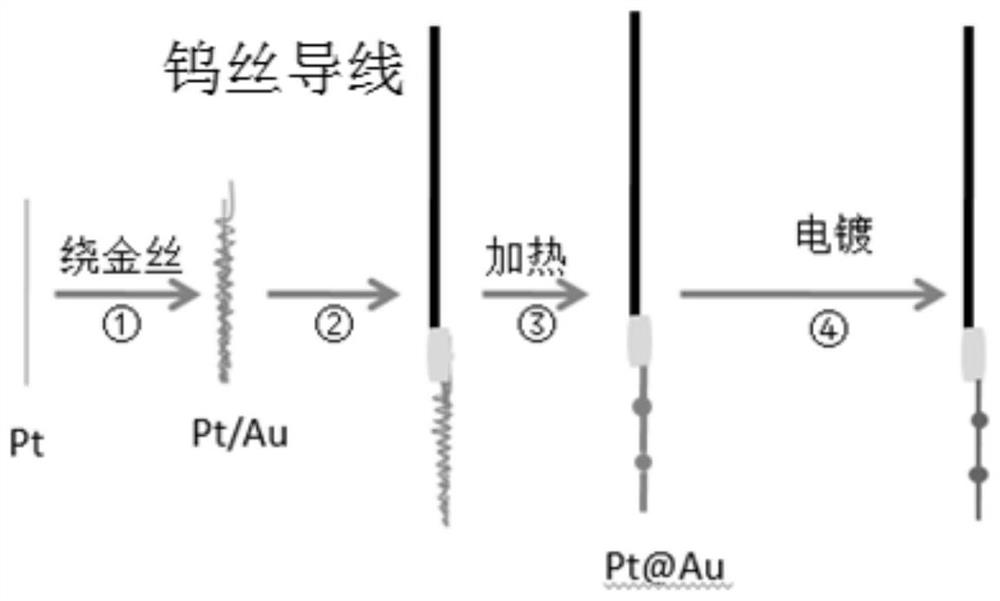

[0034] A method for preparing an Au@Pt core-shell ultramicroelectrode, the schematic diagram of which is shown in Figure 1, includes the following steps:

[0035] Step 1) take a gold wire with a diameter of 25 μm, and wind it densely on a platinum wire with a diameter of 25 μm to obtain a gold-platinum wire;

[0036] Step 2) Cut out a small section of the dense gold-platinum wire wrapped with gold wire in step 1, about 1 to 2 cm long, stick it to the end of the tungsten wire with conductive silver paste, and put it in a constant temperature to dry oven (35°C-60°C, 15min-30min), after the conductive silver paste is dried, then coat the surface coated with conductive silver paste with a layer of insulating and high-temperature-resistant epoxy resin glue, so that the gold-platinum wire is more Firmly stick to the tungsten wire;

[0037] Step 3) Place the gold-platinum wire sticking to the tungsten wire in step 2 on the outer flame of the alcohol lamp. Because the melting point o...

Embodiment 2

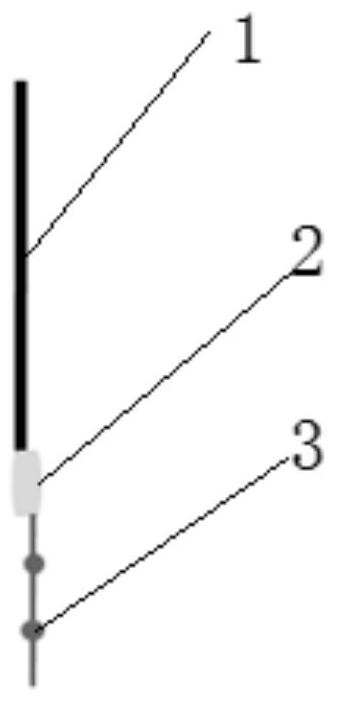

[0040] Such as figure 2 As shown, an Au@Pt core-shell ultramicroelectrode includes a tungsten wire 1, a conductive colloid layer 2 and an Au@Pt core-shell 3, and one end of the tungsten wire passes through the conductive colloid layer 2 and the Au@Pt core-shell One end of the body 3 is glued and fixed, the conductive adhesive layer is coated with insulating colloid, and the Au@Pt core shell is electroplated with an insulating layer.

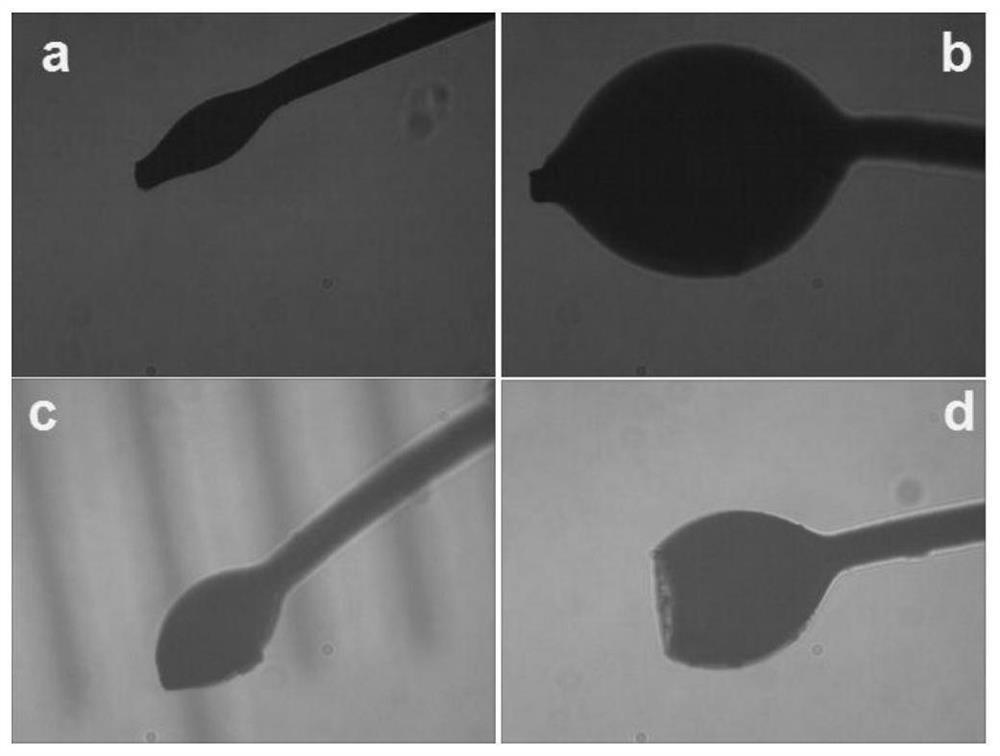

[0041] image 3 and Figure 4 They are micrographs of Au@Pt core-shell ultramicroelectrodes with different gold / platinum ratios prepared in the present invention and their cyclic voltammograms in 1 mmol / L ferrocene methanol solution. From image 3 and Figure 4 It can be seen from the figure that the present invention can obtain Au@Pt core-shell ultramicrodisk electrodes with different gold / platinum ratios by cutting different parts of the Au@P core-shell. The radii of the Au@Pt core-shell ultramicroelectrodes a to d obtained in this experi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com