Method for manufacturing spliced large-caliber photon sieve

A production method and technology of photon sieves, applied in the field of optics, can solve problems such as splicing errors and photon sieve resolution reduction, so as to reduce the difficulty of splicing and ensure the image quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

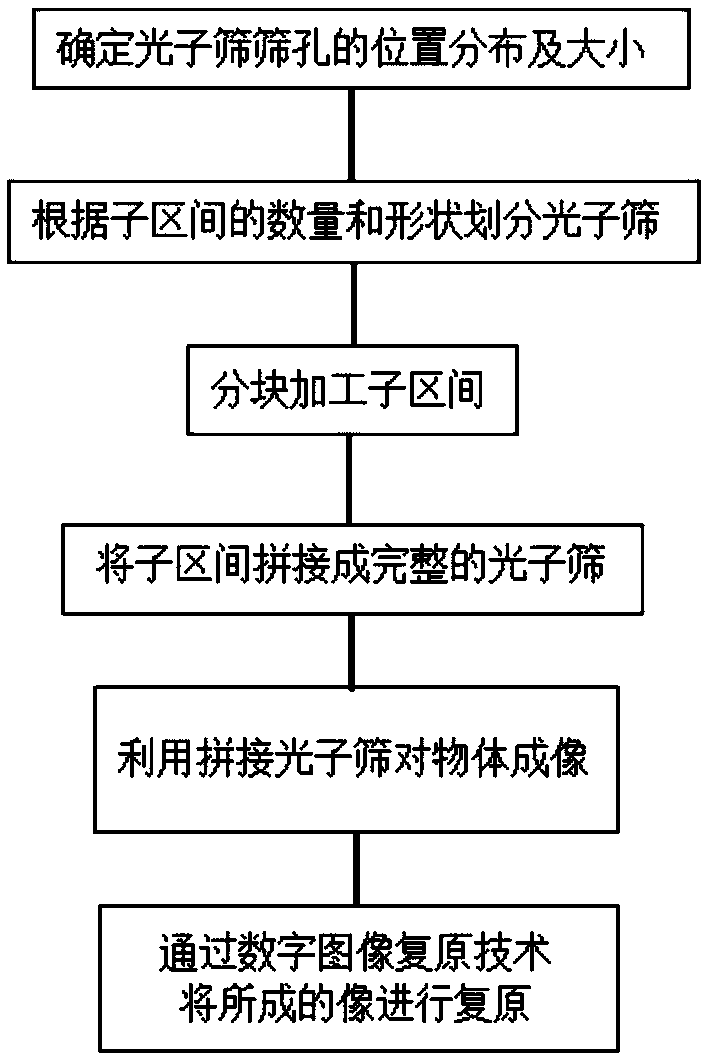

[0036] A manufacturing method of splicing large aperture photonic sieve, such as figure 1 shown, including the following steps:

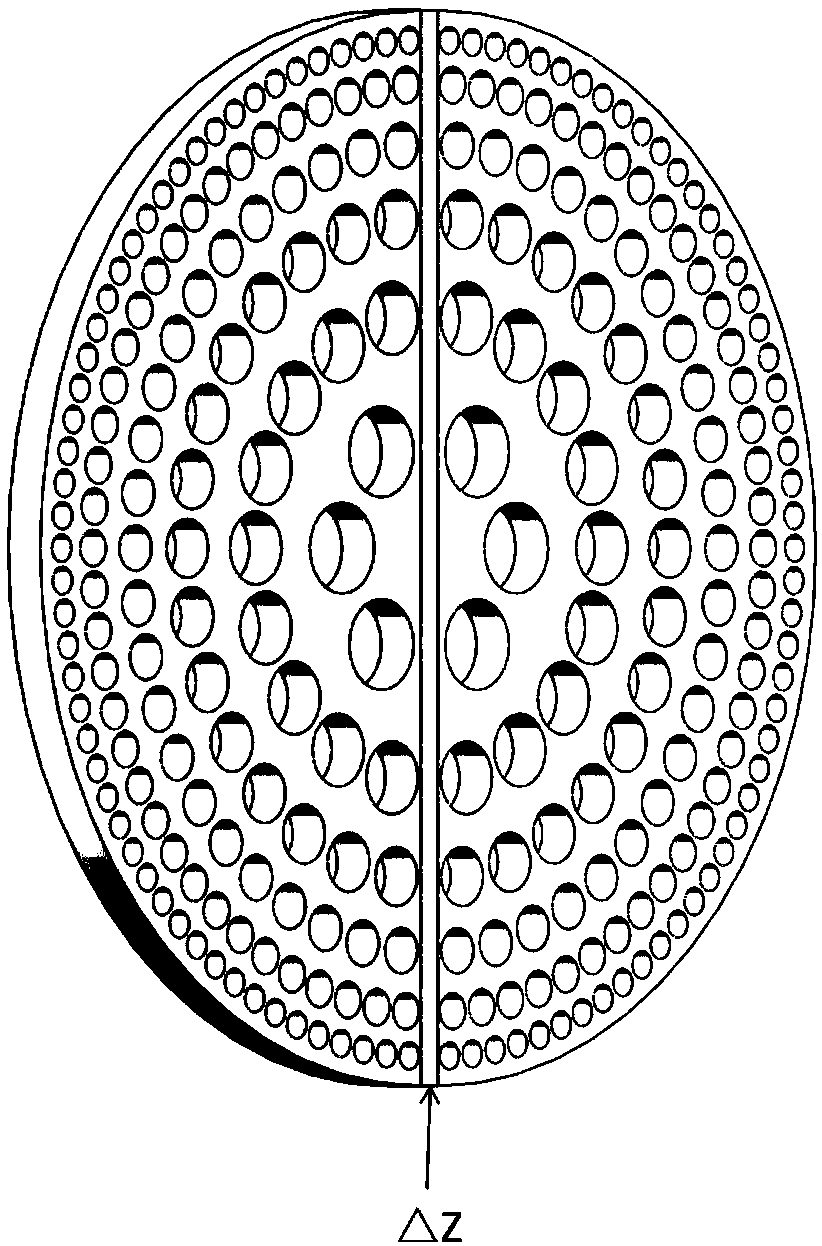

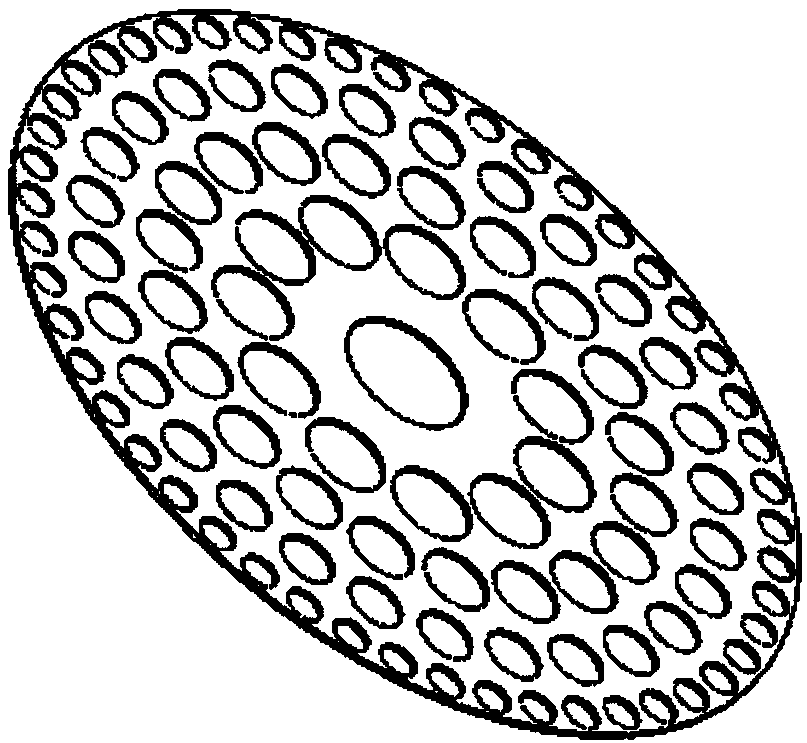

[0037] The first step is to design a large aperture photonic sieve, image 3 Shown is a complete schematic diagram of the photon sieve structure, with a diameter of D, where the position distribution of the photon sieve light holes satisfies the equation:

[0038]

[0039] In the formula, f is the focal length of the photon sieve, n is the ring band number of the optical ring, λ is the working wavelength of the photon sieve, R is the radius of the photon sieve, α is the cubic coding coefficient, k is the wave number, x m and y m is the center position of the mth pinhole on the nth pass ring. The aperture diameter d of the photon sieve is set as a multiple of the bright ring band width of the Fresnel zone plate. where the width of the bright ring band of the Fresnel zone plate

[0040] In this embodiment, the third-order coding coefficient...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com