A high-strength light-weight wear-resistant communication optical cable

A communication optical cable, high-strength technology, applied in the field of high-strength, light-weight, wear-resistant communication optical cables, can solve the problems of non-recycling, etc., and achieve the effects of improving protection ability, high wear resistance and strength, and improving strength and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

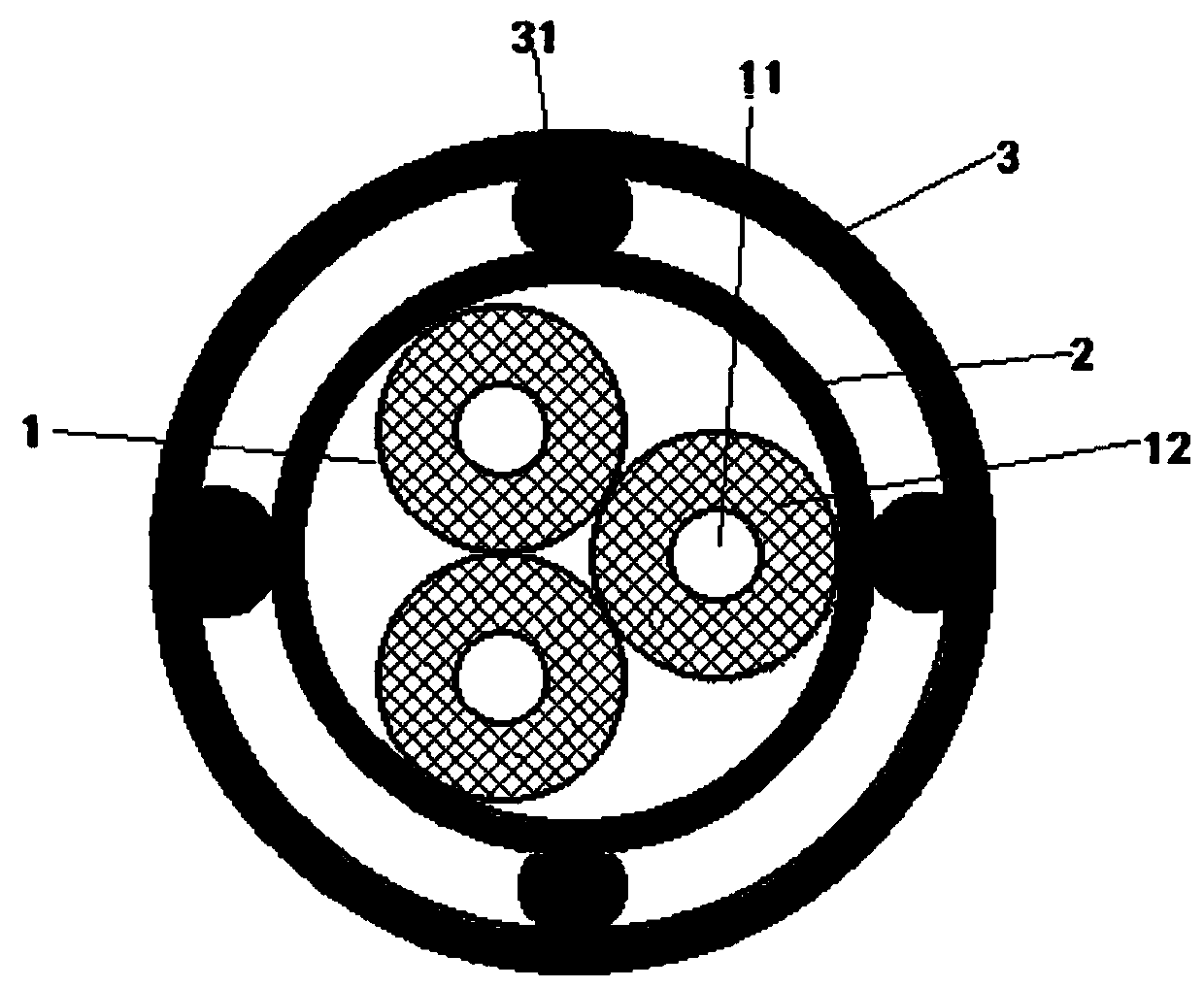

[0023] A high-strength light-weight wear-resistant communication optical cable, such as figure 1 As shown, it includes several cable core assemblies 1, the outside of the cable core assembly 1 is provided with a central sleeve 2, the cable core assembly 1 includes a cable core 11 and a sheath 12 sleeved and fixed on the outside of the cable core, the central sleeve 2 The outer casing is provided with a reinforcing tube 3, and the inner surface of the side wall of the reinforcing tube 3 is evenly distributed with a number of reinforcing bars 31 at an equal angle. There is a gap with the central sleeve 2, which can reduce the weight of the optical cable while improving the strength of the optical cable;

[0024] A layer of high-strength elastic sleeve is provided on the peripheral fastening sleeve of the reinforcing tube 3;

[0025] The sheath 12 and the central sleeve 2 are made of one of polyphenylene ether material, polyphenylene sulfide material and polyarylate material;

...

Embodiment 2

[0034] The structure of the communication optical cable is the same as that of Example 1, and the preparation process of the rubber slurry is different; wherein the preparation process of the rubber slurry is: add 10 kg of bromobutyl rubber to 45 kg of chloroform, heat up to 70 ° C and stir to dissolve, and then add 0.5kg of crosslinking agent, 0.7kg of accelerator, 0.08kg of sulfur, 0.7kg of zinc oxide and 3.4kg of carbon black were added therein, and the rubber slurry was obtained after stirring and mixing evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com