Photovoltaic solder strip, manufacturing method, solar cell string and solar cell module

A technology for solar cells and photovoltaic ribbons, applied in the fields of photovoltaic power generation, electrical components, circuits, etc., can solve the problems of increased internal resistance, multi-cell light receiving area, affecting the power of components, etc., to improve the conversion rate and improve the conversion rate. , the effect of the simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The exemplary embodiments will be described in detail here, and examples thereof are shown in the accompanying drawings. When the following description refers to the accompanying drawings, unless otherwise indicated, the same numbers in different drawings represent the same or similar elements. The implementation manners described in the following exemplary embodiments do not represent all implementation manners consistent with the present invention. Rather, they are merely examples of devices and methods consistent with some aspects of the present invention as detailed in the appended claims.

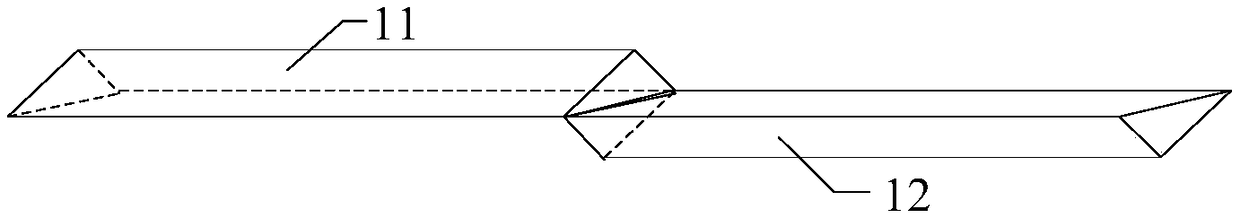

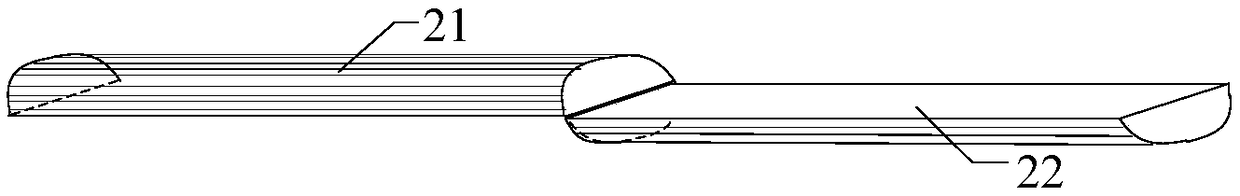

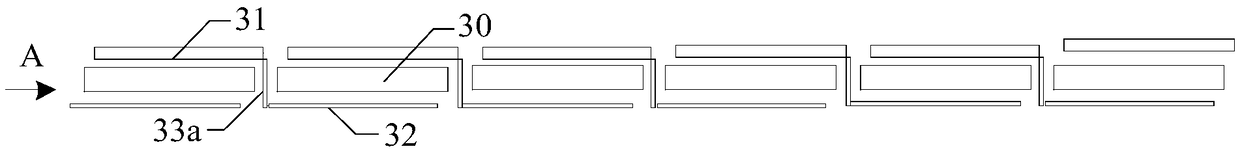

[0029] In order to improve the conversion rate of the solar cell module, this application has specially designed the soldering ribbon in the solar cell module. Combine below Figure 1A to Figure 3 Examples of solar cell modules, solar cell strings and photovoltaic ribbons are given.

[0030] The solar cell module provided in this application includes an interconnection bar and at l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com