An integrated structure of a power battery module and a liquid cooling system

A battery module and power battery technology, which is applied to battery pack parts, structural parts, secondary batteries, etc., can solve the cumbersome assembly process of liquid-cooled battery packs, poor temperature uniformity of single cells, and battery charging and discharging. Poor performance and other problems, to achieve the effect of simplifying hoisting, eliminating assembly and coordination problems, and improving energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

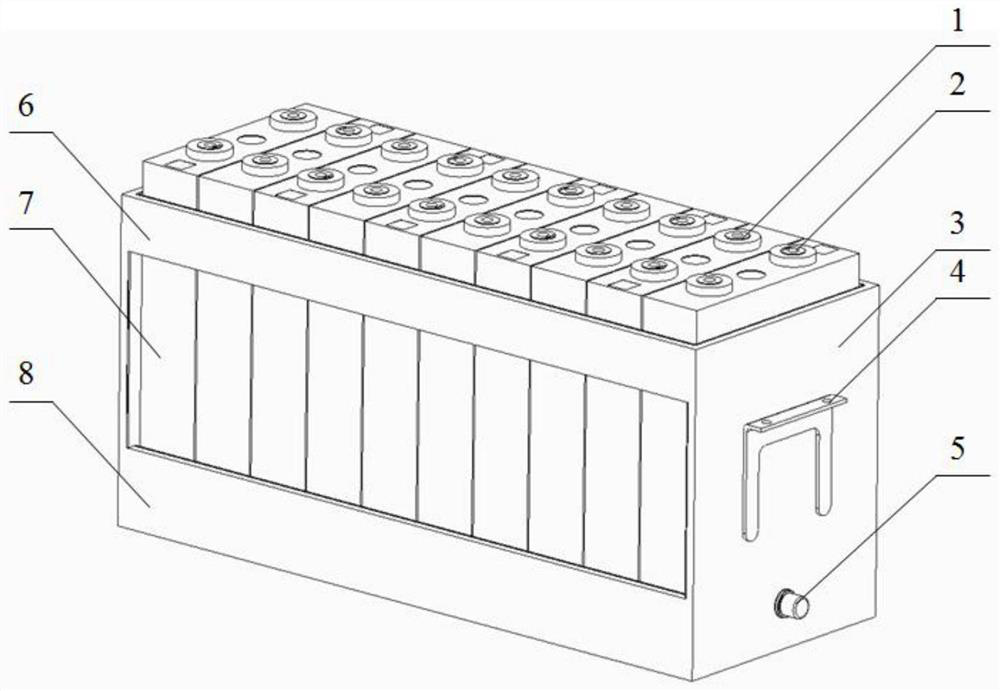

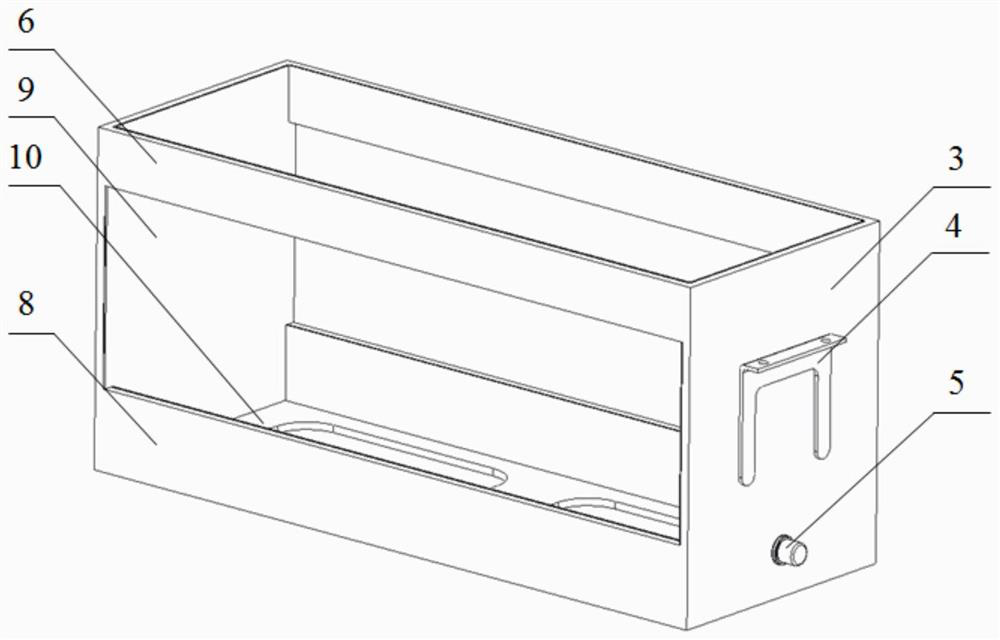

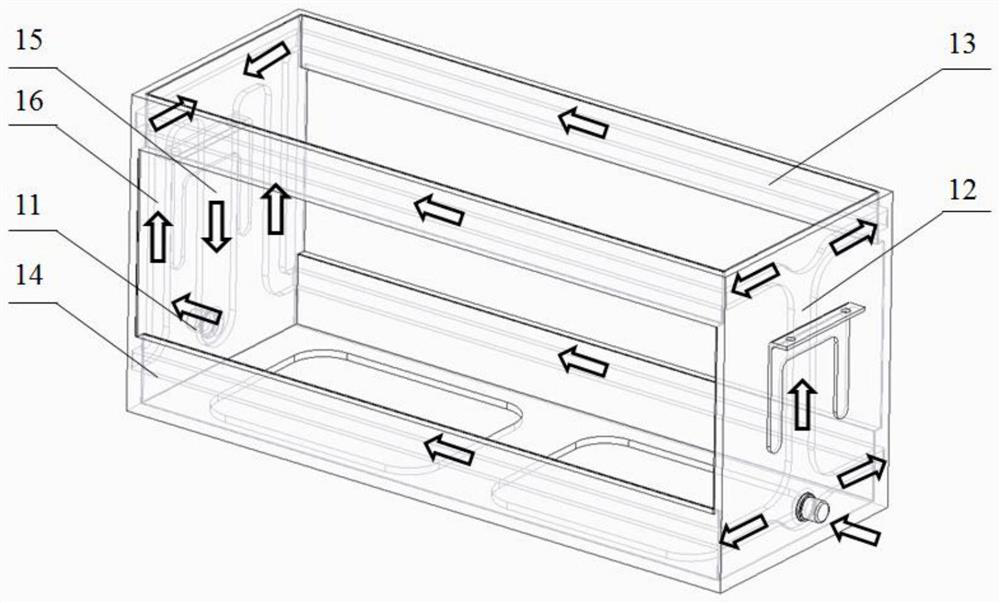

[0026] Such as Figure 1 to Figure 6 As shown, an integrated structure of a power battery module and a liquid cooling system according to the present invention includes a battery module and a module frame, the battery module is formed by a plurality of single cells 7 arranged in parallel, and the battery module In the module frame, a cooling chamber is provided in the module frame, and a liquid inlet 5 and a liquid outlet 11 are provided on the outer wall of the module frame, and the liquid inlet 5 and the liquid outlet 11 communicate with the cooling chamber ; Both the liquid inlet 5 and the liquid outlet 11 are provided with a guide block 17, the guide block 17 is conical, and the cone tip of the guide block 17 is set outward.

[0027] Hanging lugs 4 are provided on the outer wall of the module rack.

[0028] There are interconnected cavity flow passages inside the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com