Cleaning robot for glass curtain wall

A technology for cleaning robots and glass curtain walls, applied in robot cleaning machines, cleaning machinery, machine parts, etc., can solve the problems of high labor consumption, low cleaning efficiency, low cleaning efficiency, etc., achieve a high degree of automation, ensure cleanliness, fast moving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

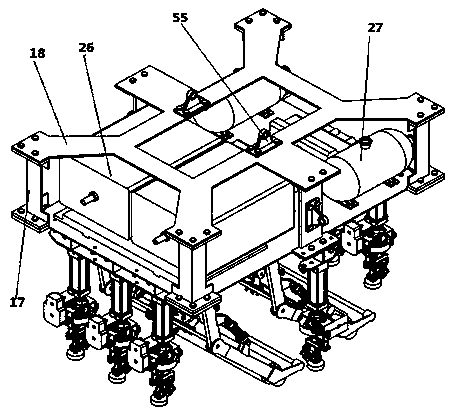

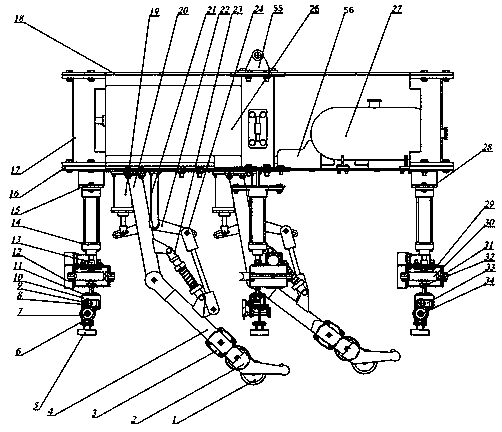

[0041] Embodiment 1: as Figure 1~11 As stated, the glass curtain wall cleaning robot includes 8 telescopic support arm parts, 1 telescopic roller brush cleaning part, mobile bracket guide rail parts and connecting parts;

[0042] The 8 telescopic supporting arm parts are respectively arranged under the connecting part, the mobile bracket rail part is connected with the connecting part, the connecting part is connected with the top of the telescopic roller brush cleaning part, and the telescopic roller The brush cleaning part is positioned at the inner side of 8 telescopic support arm parts.

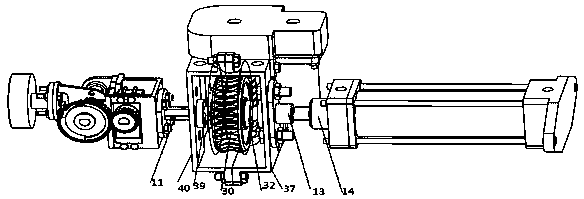

[0043] The telescopic support arm parts include suction cup 5, suction cup fixing frame I6, half gear 7, full gear 8, steering gear fixing frame II10, connector I11, gear box 12, steering gear 33, suction cup rotating shaft 34, suction cup cover 36, worm 29. Worm gear 30, worm gear shaft 32, turbine upper cover 37, motor I38, worm gear lower cover 40, piston connector II13, cylinder I14...

Embodiment 2

[0053] Embodiment 2: The structure of this embodiment is the same as that of Embodiment 1, the difference is that the middle two support beams I17 of the six support beams I17 are respectively provided with lifting lugs II55, and in the two liquid storage containers 26, One of the liquid storage containers is filled with foam, and the other liquid storage container is filled with clear water. The two rolling brushes 1, the rolling brush 1 in the front row is a foam brush, and the rolling brush 1 in the rear row is a clean water brush. The cylinder I14, fixed The block III28 and the bottom plate I16 are connected by bolts III15, and the ends of the oblique fixed arm 20 and the roller brush support arm 4 are installed with obstacle detection devices.

[0054] The working principle of this glass curtain wall cleaning robot is as follows:

[0055] The expansion and contraction of the telescopic support arm is realized by the expansion and contraction of the cylinder I piston rod. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap