Small-sized self-adaptive vehicle washing machine

A self-adaptive, car washing machine technology, applied in vehicle maintenance, vehicle cleaning, vehicle drying devices, etc., can solve problems such as difficult to meet vehicle cleaning requirements, achieve the goal of improving market competitiveness, improving car washing efficiency, and ensuring system torque requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

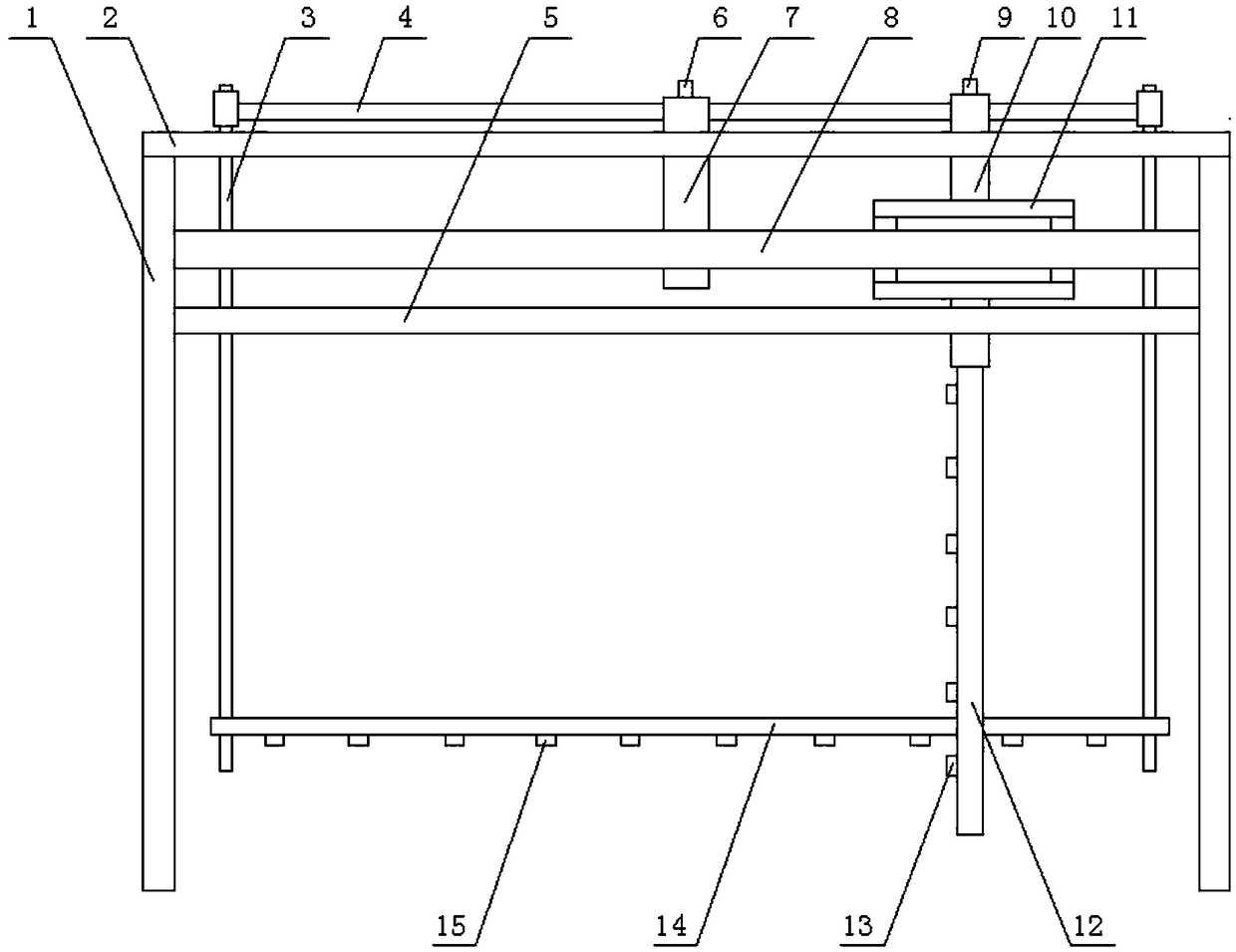

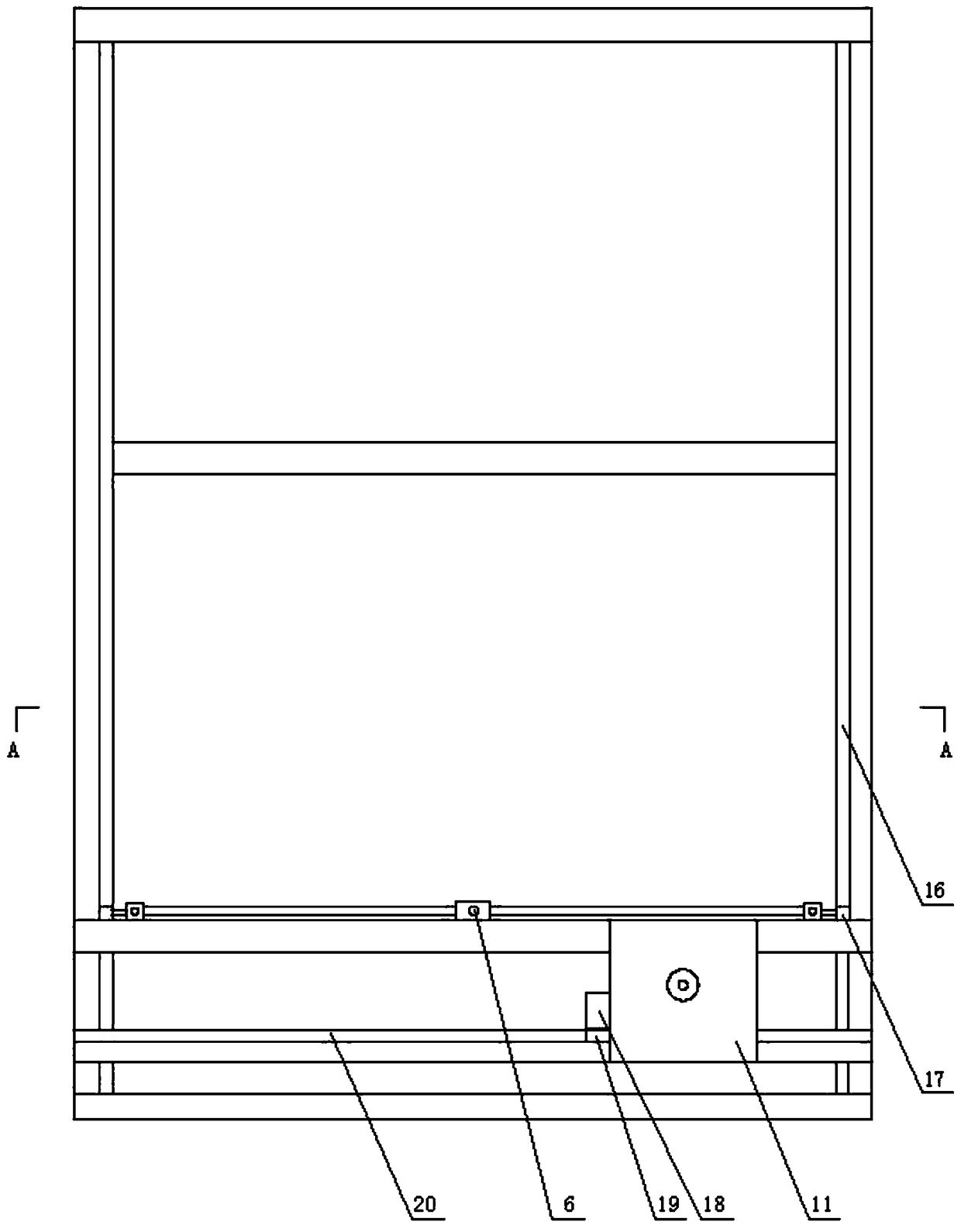

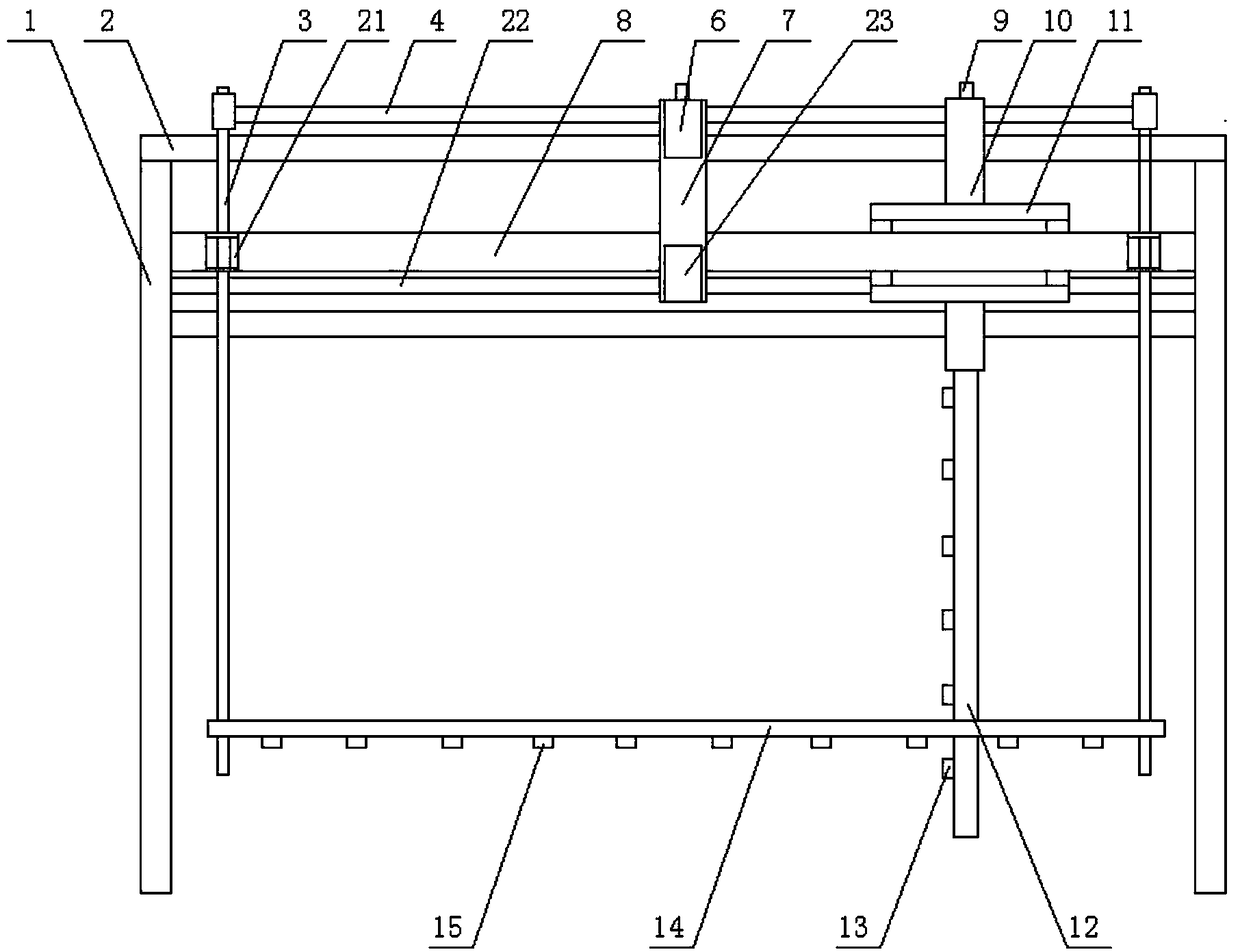

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

[0027] A small adaptive car washing machine such as Figure 1 to Figure 3 As shown, it includes a rectangular main frame and a control device. The rectangular main frame includes two front-end columns 1, an upper beam 2 and a lower beam 5 between the two front-end columns, two rear-end columns and between the two rear-end columns. The upper crossbeam 2 and the lower crossbeam 5 and some pairs of middle columns, the upper beam and the front and rear moving track 16 are installed from top to bottom between the front and rear end columns on the left and right sides, and the front and rear moving tracks are equipped with two front and rear The platform support frame 8 that mobile track moves. A mobile platform 11 that can move left and right is installed on the platform support frame. On the left and right moving rails 20 on the platform support frame.

[0028] A rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com