Permanent magnet brushless motor Hall position sensor fault diagnosis method

A permanent magnet brushless motor and sensor fault technology, applied in the direction of electric/magnetic position measurement, using electric devices, electromagnetic measuring devices, etc., can solve the problems of poor practicability, achieve good practicability, improve reliability, and ensure reliable operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

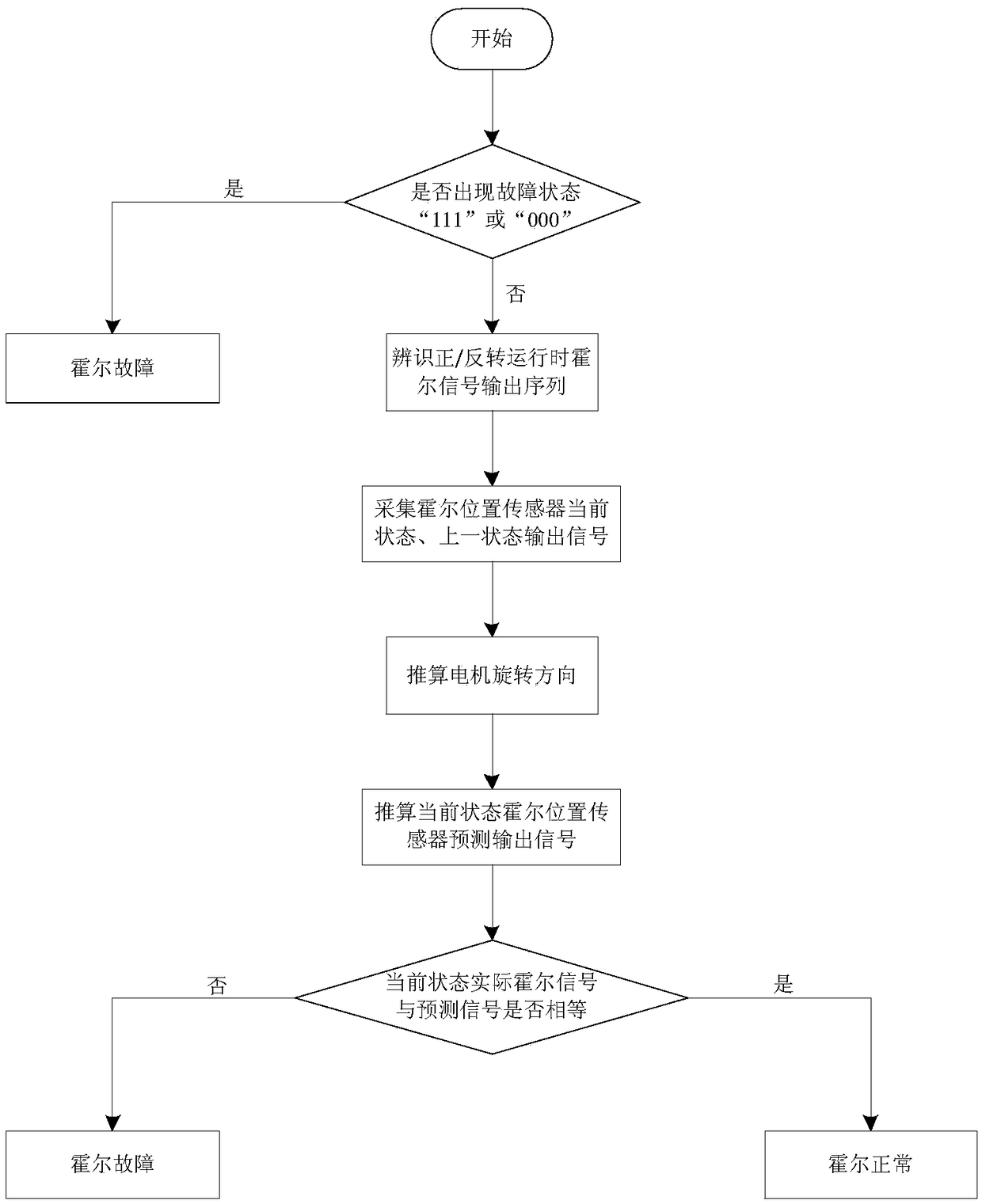

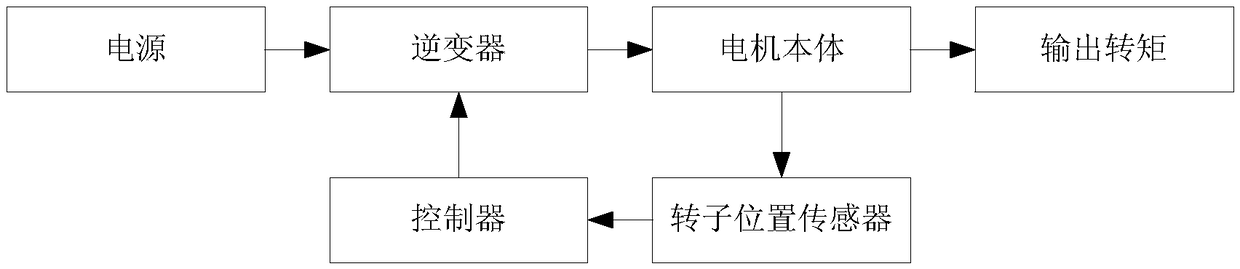

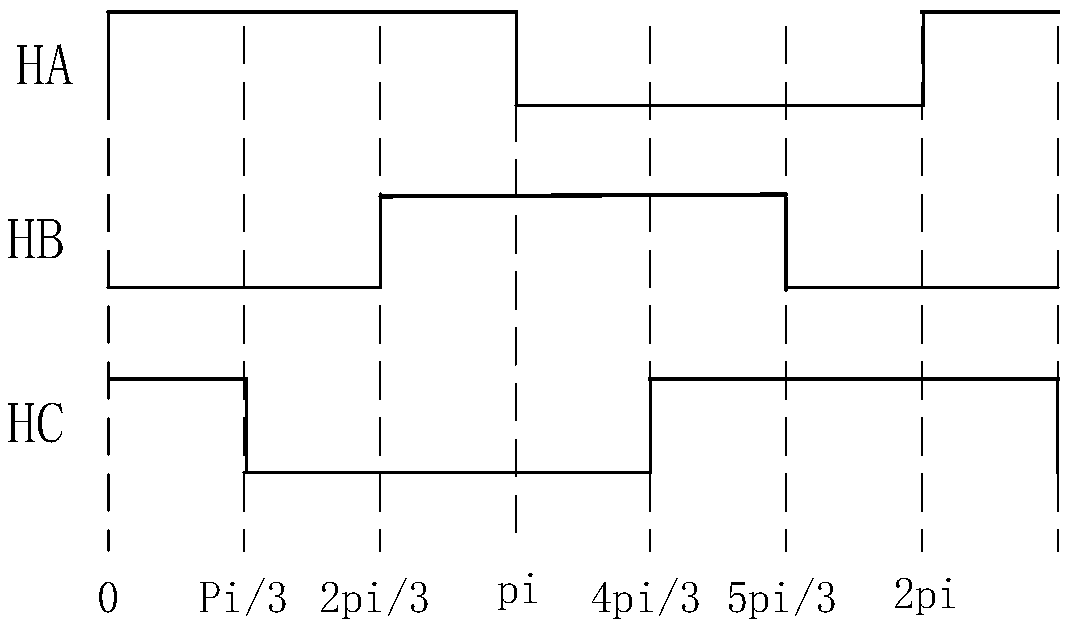

[0025] The following examples refer to Figure 1-4 .

[0026] In this embodiment, TMS320F2812 of Texas Instruments is used as the control chip, IR2136 is used as the driver chip, and a three-phase bridge circuit is used to drive the permanent magnet brushless motor.

[0027] The specific steps of the fault diagnosis method for the hall position sensor of the permanent magnet brushless motor of the present invention are as follows:

[0028] Step 1. When the permanent magnet brushless motor is running, the three-way Hall position sensor can output up to eight states of "000, 001, 010, 011, 100, 101, 110, 111", among which "000, 111" are failure state. A one-dimensional array Hall with a length of 8 is used to represent the eight states respectively, among which Hall[0] and Hall[7] are fault states, and the system judges whether the Hall position sensor has a fault state by detecting whether the Hall sensor has a fault state. Fault. If the Hall position sensor has a "111" fau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com