Roadway U-type steel support performance test system and test method

A technology of testing and testing methods, applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve the problem of outdated measurement and control systems and testing methods, loading methods and technical parameters that cannot meet the performance testing of roadway supports Questions such as requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

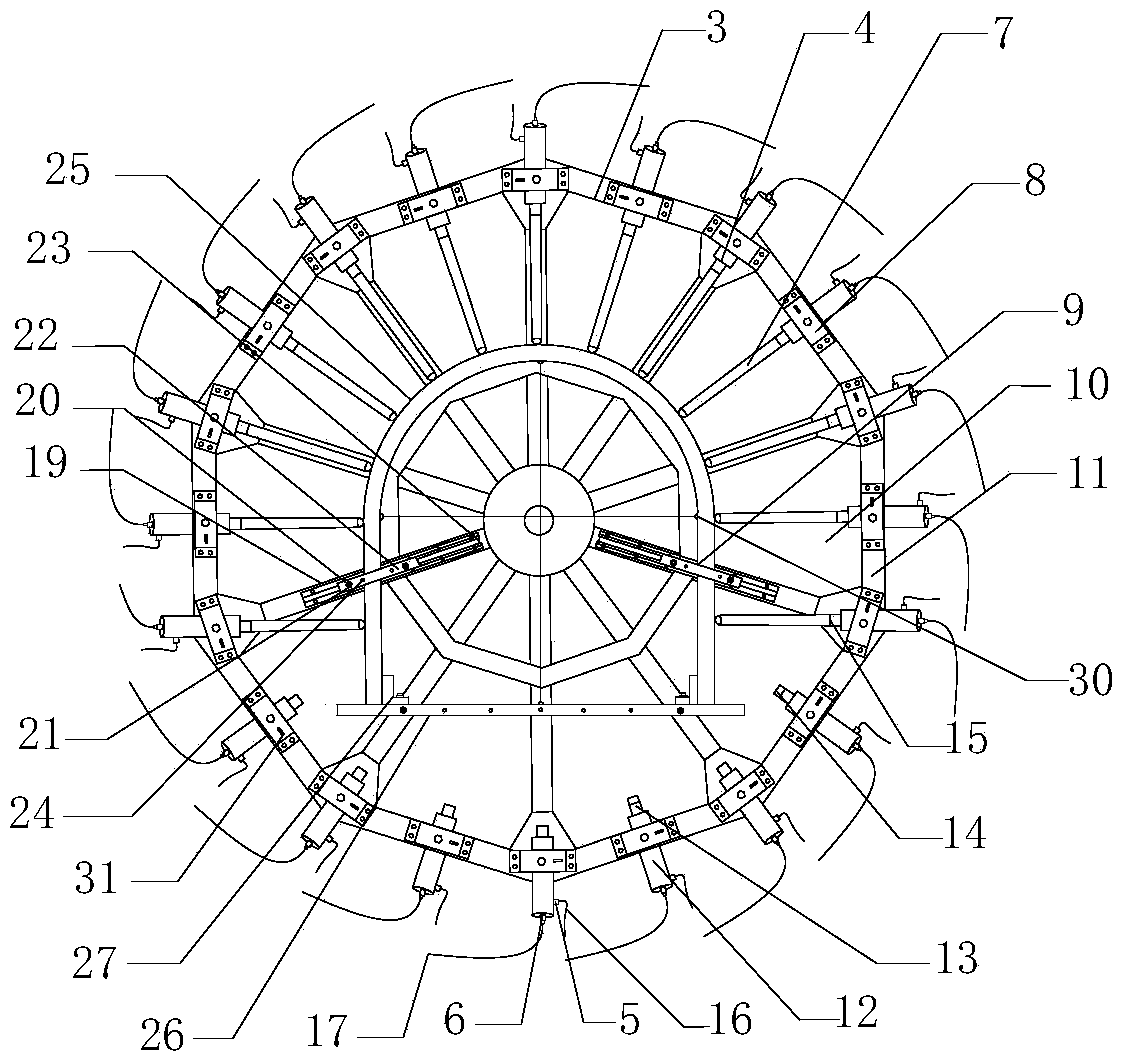

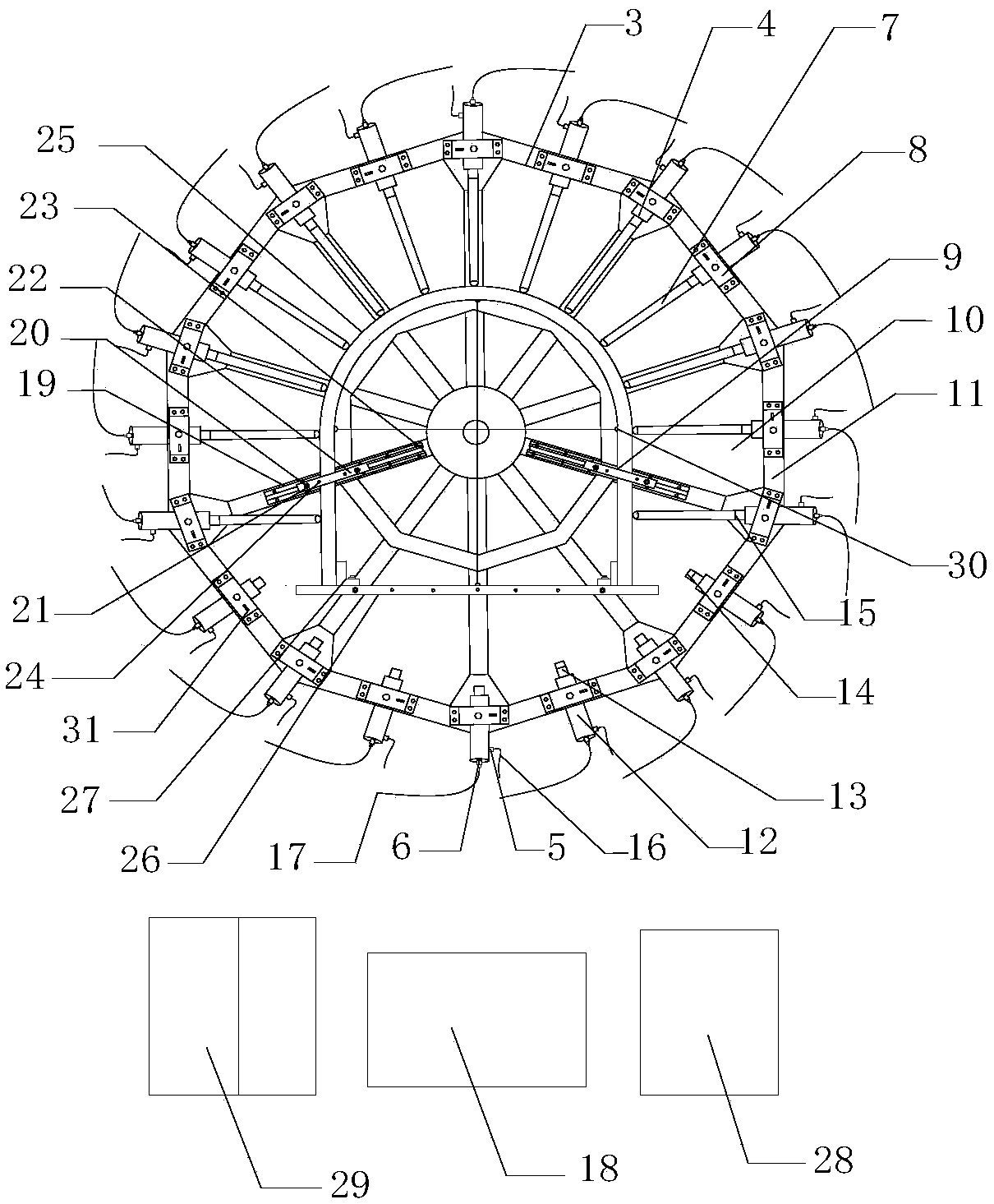

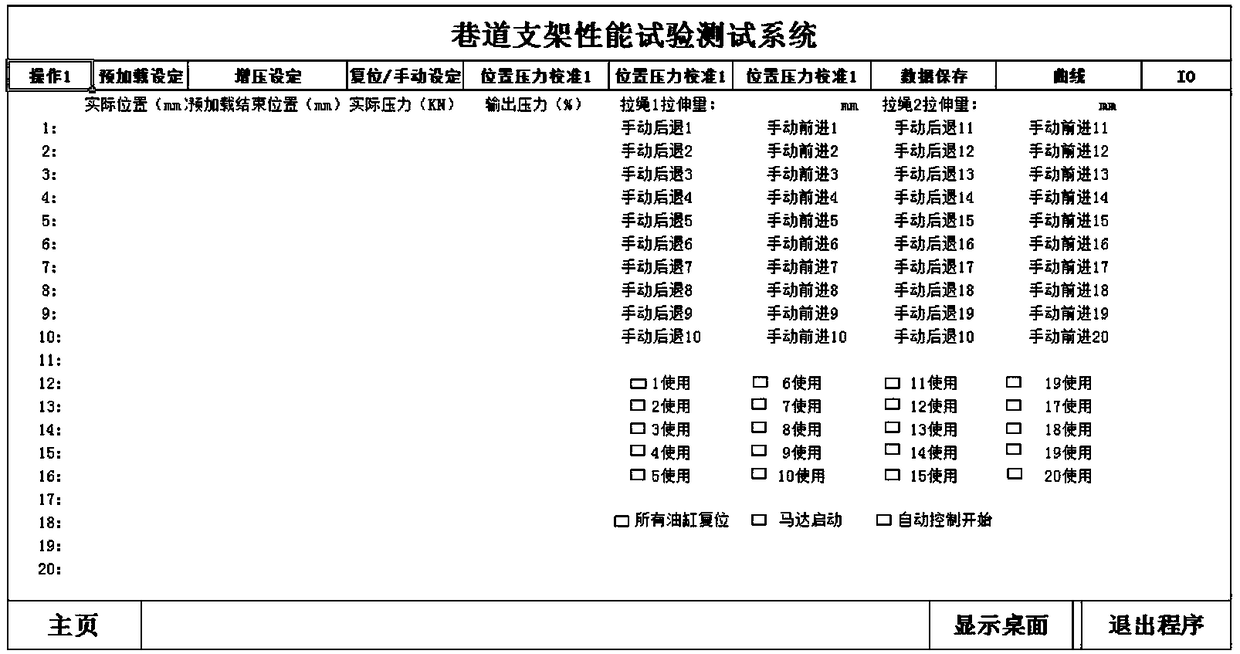

[0041] Such as figure 1 , 2 , 3, 4 shown, figure 1 It is a frame diagram of the host structure of a roadway U-shaped steel support performance test system proposed by the present invention; figure 2 It is an overall schematic diagram of a roadway U-shaped steel support performance test testing system proposed by the present invention; image 3 It is an operation 1 interface diagram of the operation interface of a roadway U-shaped steel bracket performance test test system proposed by the present invention; Figure 4 It is a preloaded interface diagram of the operation interface of the U-shaped steel bracket performance test system for roadway proposed by the present invention; Figure 5 It is a supercharging setting interface diagram of the operation interface of the roadway U-shaped steel bracket performance test test system proposed by the present invention; Figure 6 It is a reset interface diagram of the operation interface of a roadway U-shaped steel bracket performa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com