Cable cutting and stripping production line

A production line and thread cutting technology, which is applied in the direction of cable installation, cable installation device, cutting/splitting cable equipment, etc., can solve the problems of large error in cutting and stripping wires, low degree of automation, and high labor intensity, etc., to improve Product quality, wide application range, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

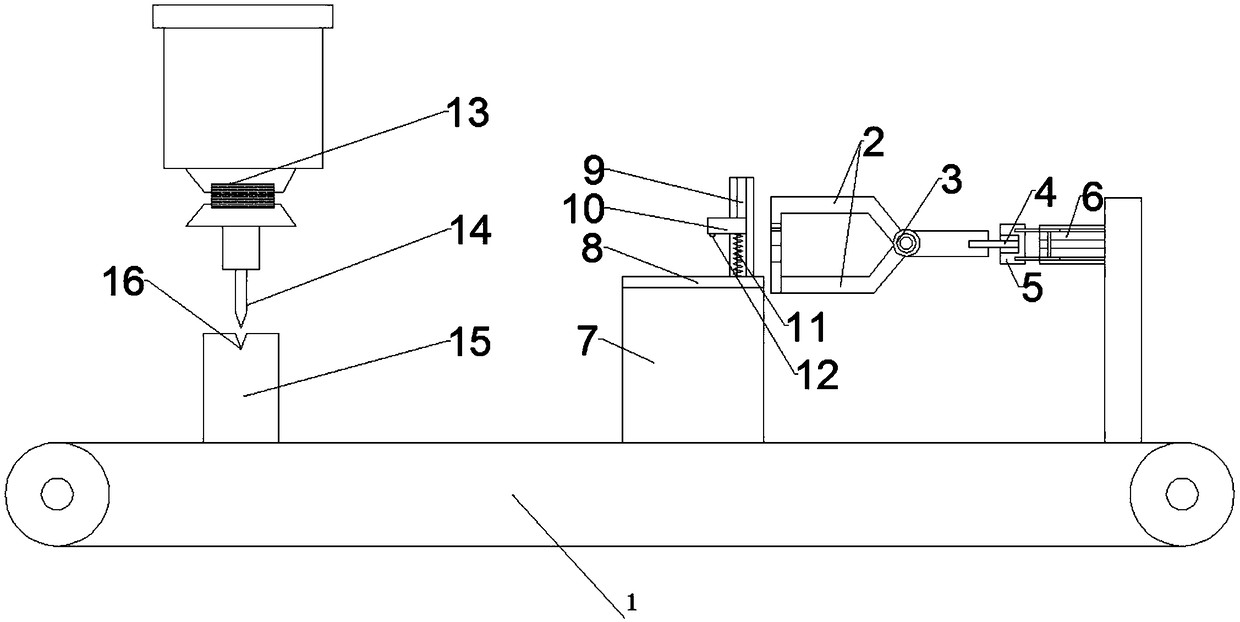

[0027] Such as figure 1 As shown, the cable cutting and stripping production line includes: a conveyor belt 1, a cutting assembly arranged beside the conveyor belt 1, an electric cable stripping assembly arranged beside the conveyor belt 1; the electric cable stripping assembly consists of: a stripping board 2, The clamp 3 connected to the head stripping board 2 is connected to the rotating motor 4 of the clamp 3 .

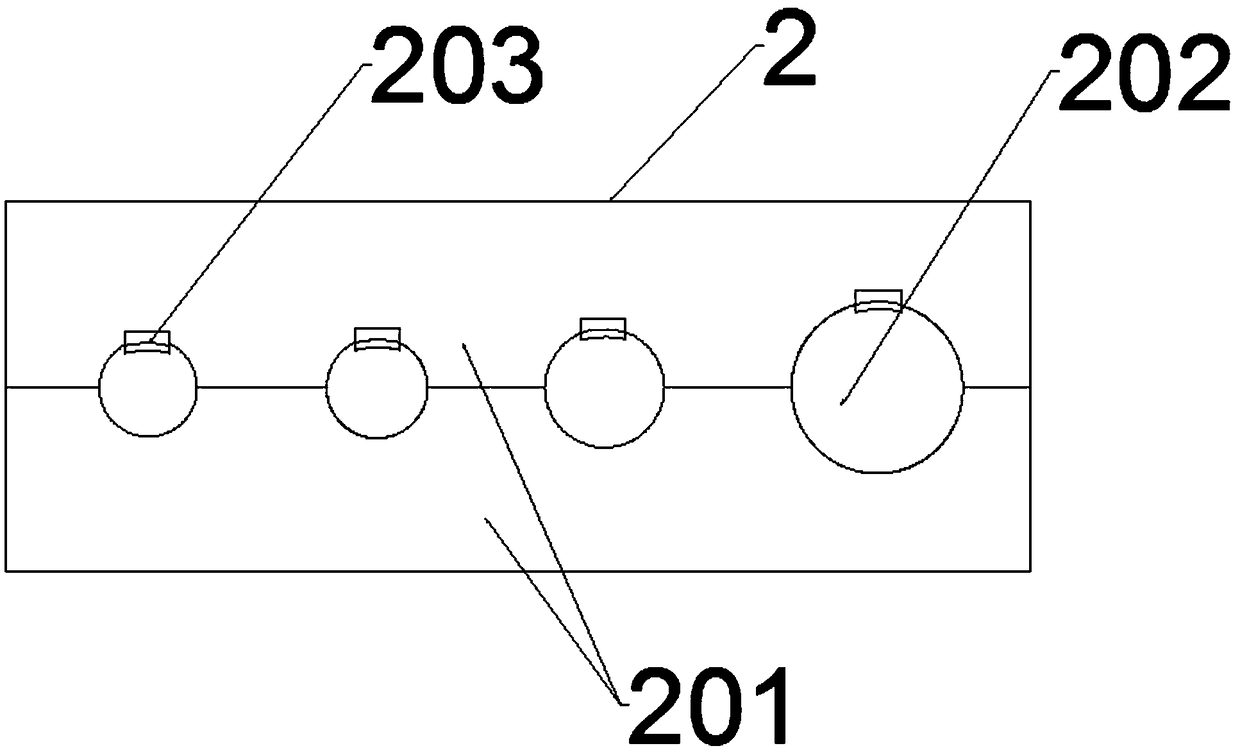

[0028] The stripping plate 2 is composed of: two stripping plate bodies 201 connected to the end positions of the splints of the clamp 3, a stripping groove 202 arranged on the edge of the stripping plate body 201, and a stripping groove 202 arranged in the stripping groove 202. blade 203 . The head stripping plate 2 cooperates with the clamp 3, so that the cable is fixed in the head stripping groove 202, the rotating motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com