Instrument and method for testing hydorgen contained in molten steel

A measuring instrument and molten steel technology, applied in the field of material analysis, can solve problems such as unsatisfactory results of hydrogen content, influence on the correct reflection of hydrogen content, easy falling off of the probe, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

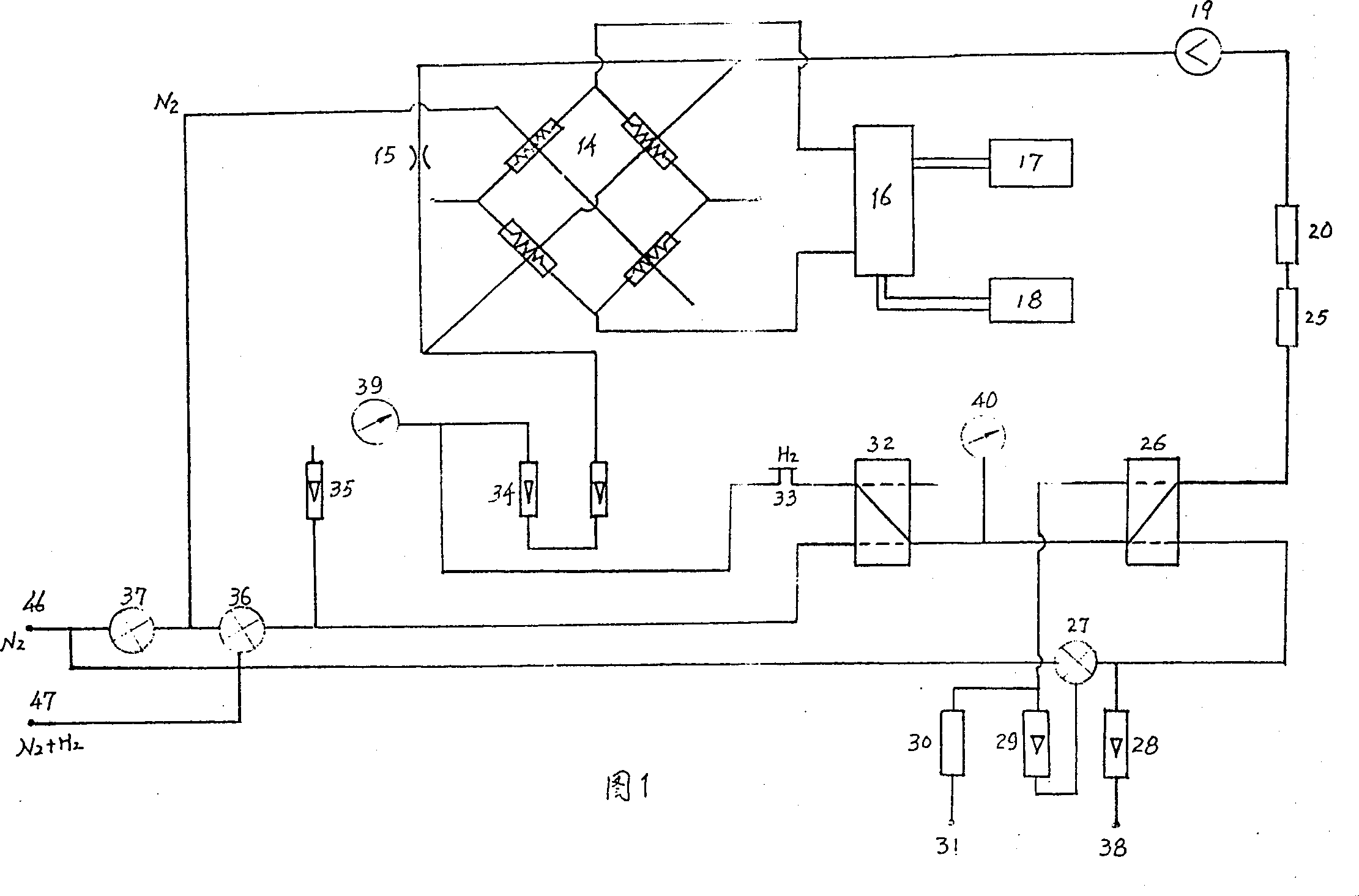

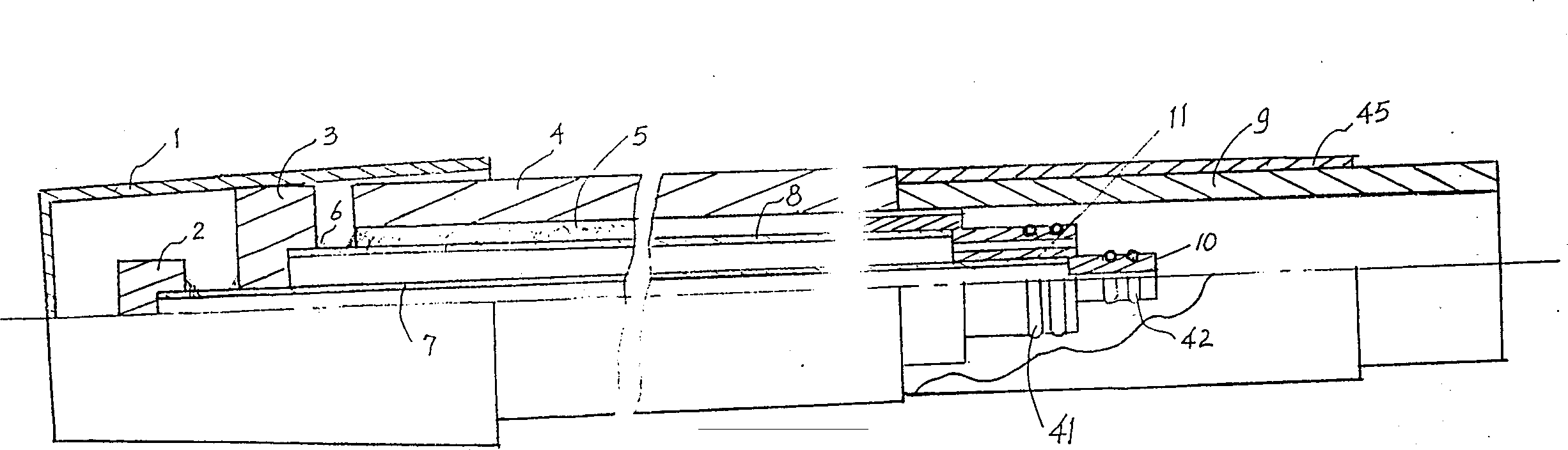

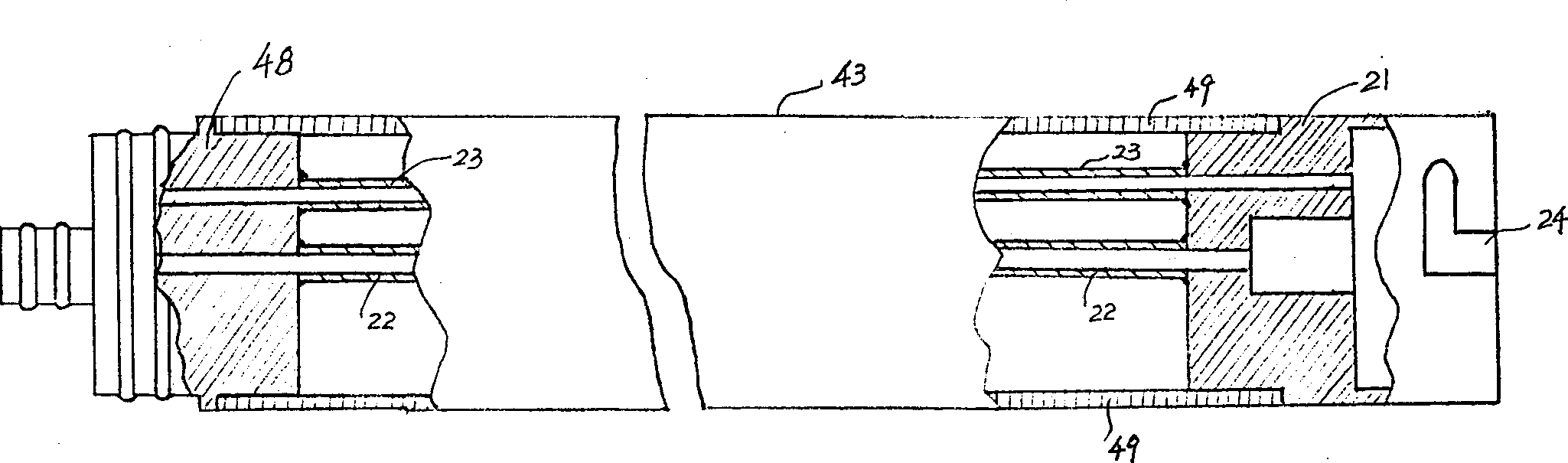

[0070] The hydrogen content in three heats of molten steel was measured by using the measuring instrument of the present invention, and the measurement was carried out in a tundish. First, connect the host part of the measuring instrument with the measuring gun and measuring head. Quickly insert the measuring head into the molten steel, start the host part at the same time, then open the switching valve 36, the pressure stabilizing valve 37 and the switching valve 27, flush all the gas circuits, then empty them, determine the baseline of the carrier gas for measurement, recirculate the measurement, and finally Closed loop measurement. The measured steel types, molten steel temperature and measurement parameters are shown in Table 1. The hydrogen content measurement results are shown in Table 2. The measurement result curve of hydrogen content is as attached Figure 5-7 shown. Attach Figure 5-7 Be respectively the hydrogen measurement curve of embodiment 1-3. In the figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com