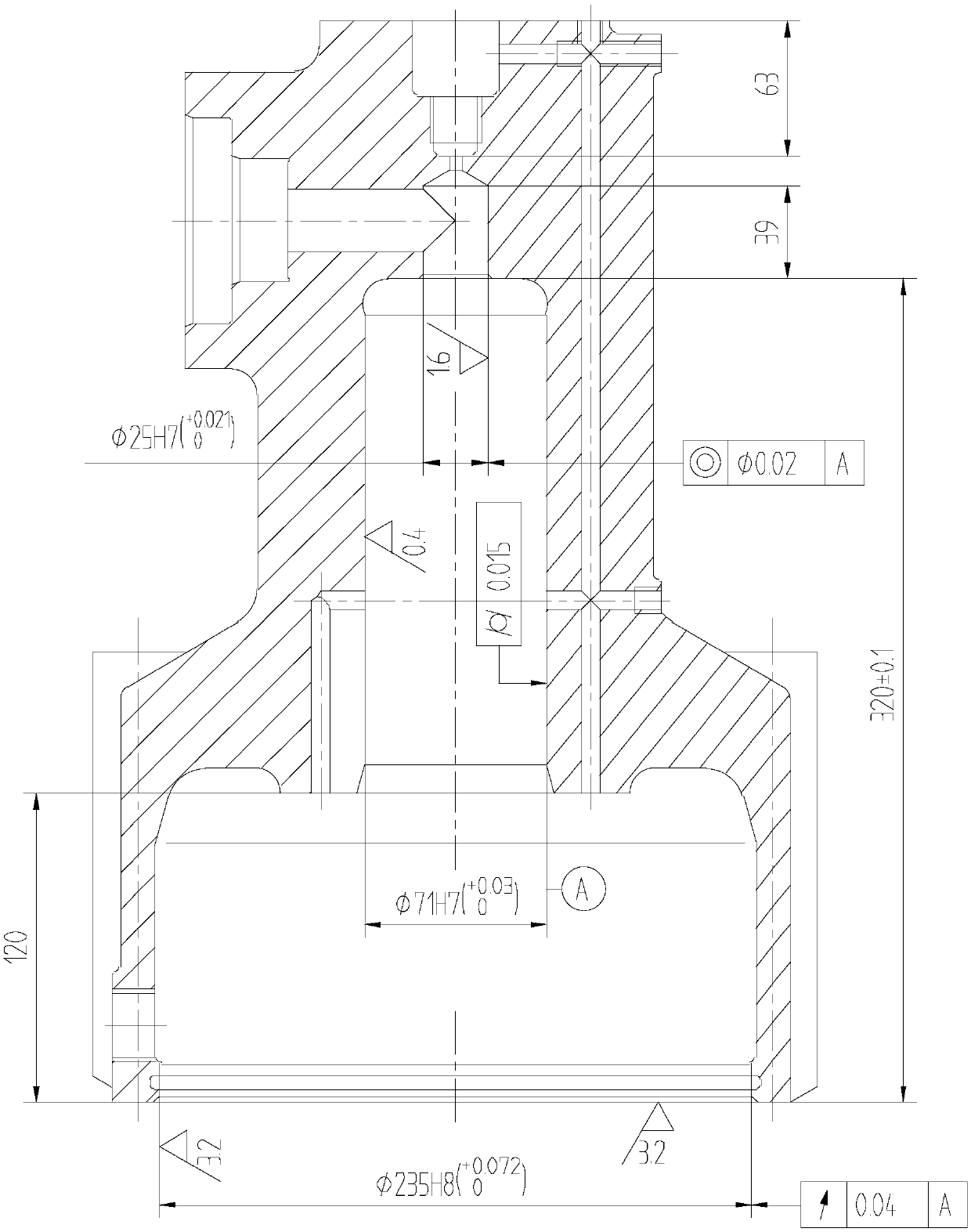

Precision machining method for blind holes of oil cylinder piston

A technology of precision machining and semi-finishing, which is applied in the field of precision machining of blind holes of oil cylinders and pistons. problems, to achieve high dimensional accuracy and shape and position accuracy, sufficient process assurance capabilities, and stable processing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

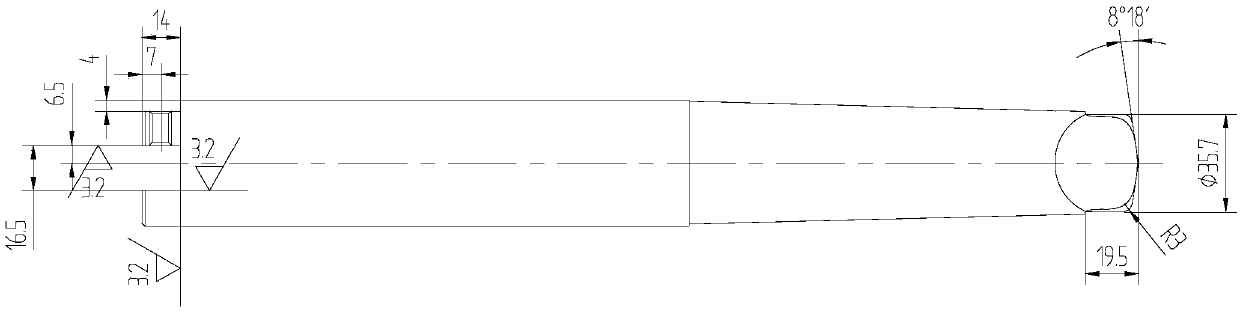

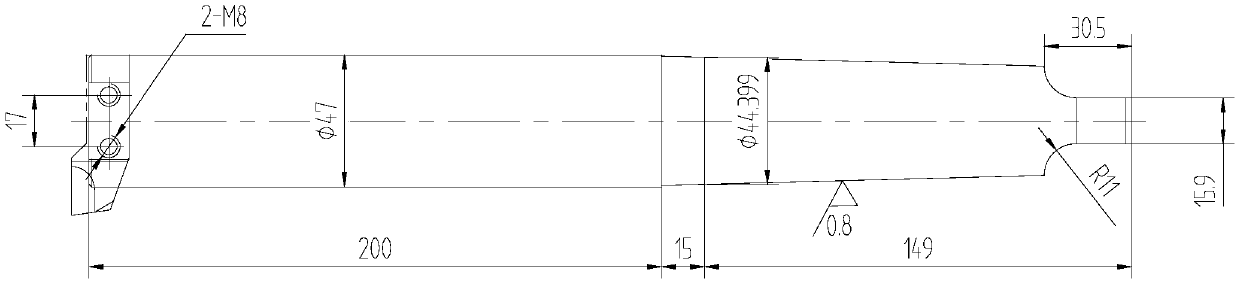

[0045] A precision machining method for a blind hole of an oil cylinder piston, comprising the following machining steps:

[0046] (1) Rough machining hole:

[0047]Before the rough machining of the blind hole of the large piston, in order to improve the rough machining efficiency and ensure the quality to serve the next process, the hole is drilled first to remove the allowance. In order to prevent and reduce the deflection of the drill bit, the following measures are adopted in the process:

[0048] a. Before drilling, process the end face of the hole to ensure that the end face is perpendicular to the axis of the drill bit;

[0049] b. First use the center drill to drill the center hole and drill a pit to guide the drill bit to drill;

[0050] c. For holes with a diameter exceeding 35mm, drilling must be performed in stages, and the diameter of the first...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com