Method for prolonging service life of numerical control milling machine

A technology of CNC milling machine and service life, which is applied in the direction of milling machines, milling machine equipment, metal processing machinery parts, etc., can solve the problems of unguaranteed precision of parts, failure of CNC milling machines, and low service life, so as to prolong service life and improve use Effect of life and life extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] use Figure 1-Figure 5 A method of prolonging the life of a CNC milling machine according to an embodiment of the present invention will be described below.

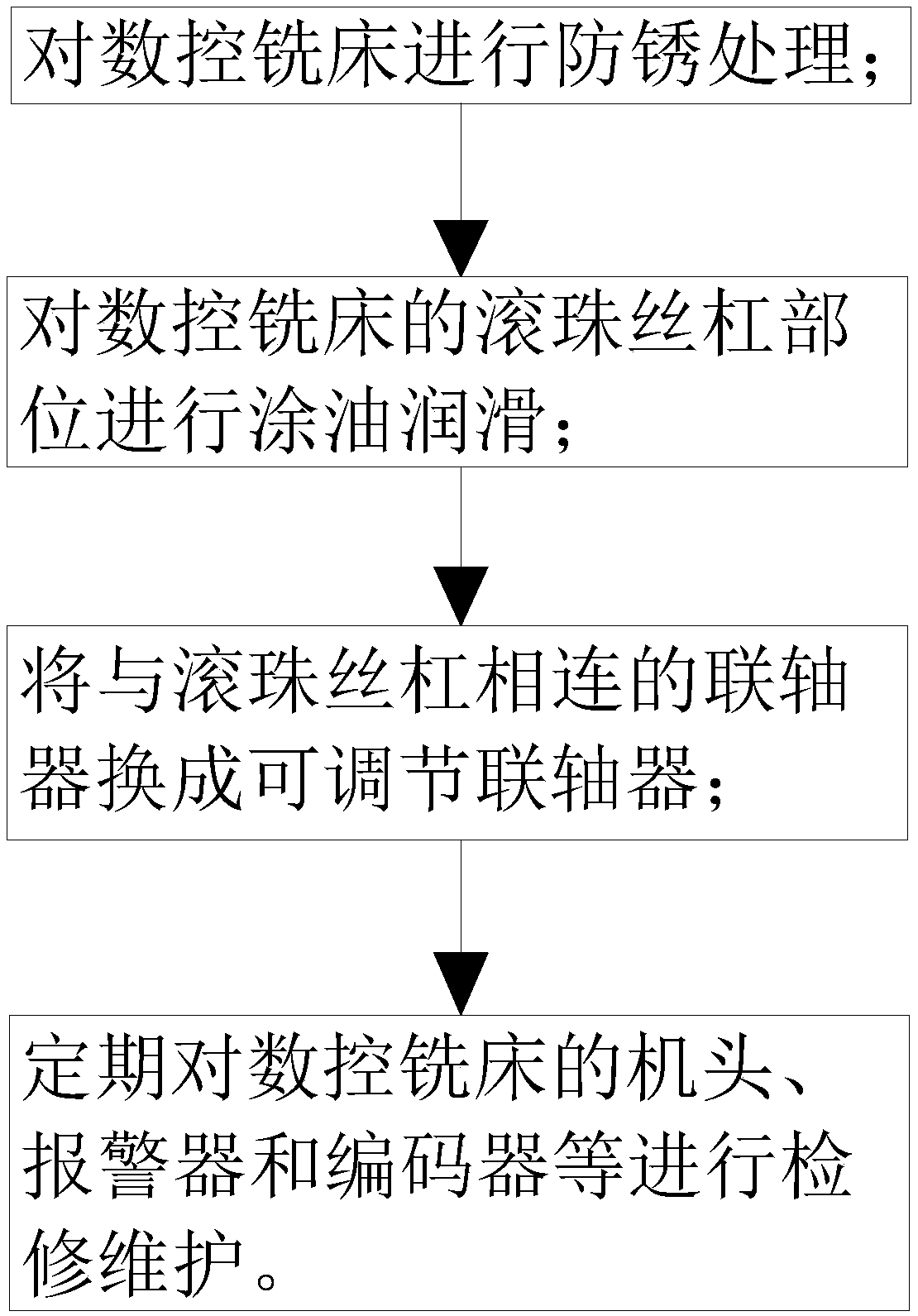

[0025] Such as Figure 1 to Figure 3 As shown, a method for prolonging the life of a CNC milling machine according to the present invention comprises the following steps:

[0026] Step 1: Carry out anti-rust treatment on the CNC milling machine;

[0027] Step 2: After the anti-rust treatment in step 1, oil the ball screw part of the CNC milling machine;

[0028] Step 3: After lubricating in step 2, replace the coupling connected to the ball screw with an adjustable coupling;

[0029] Step 4: After changing the coupling in step 3, regularly check and maintain the machine head, alarm and encoder of the CNC milling machine;

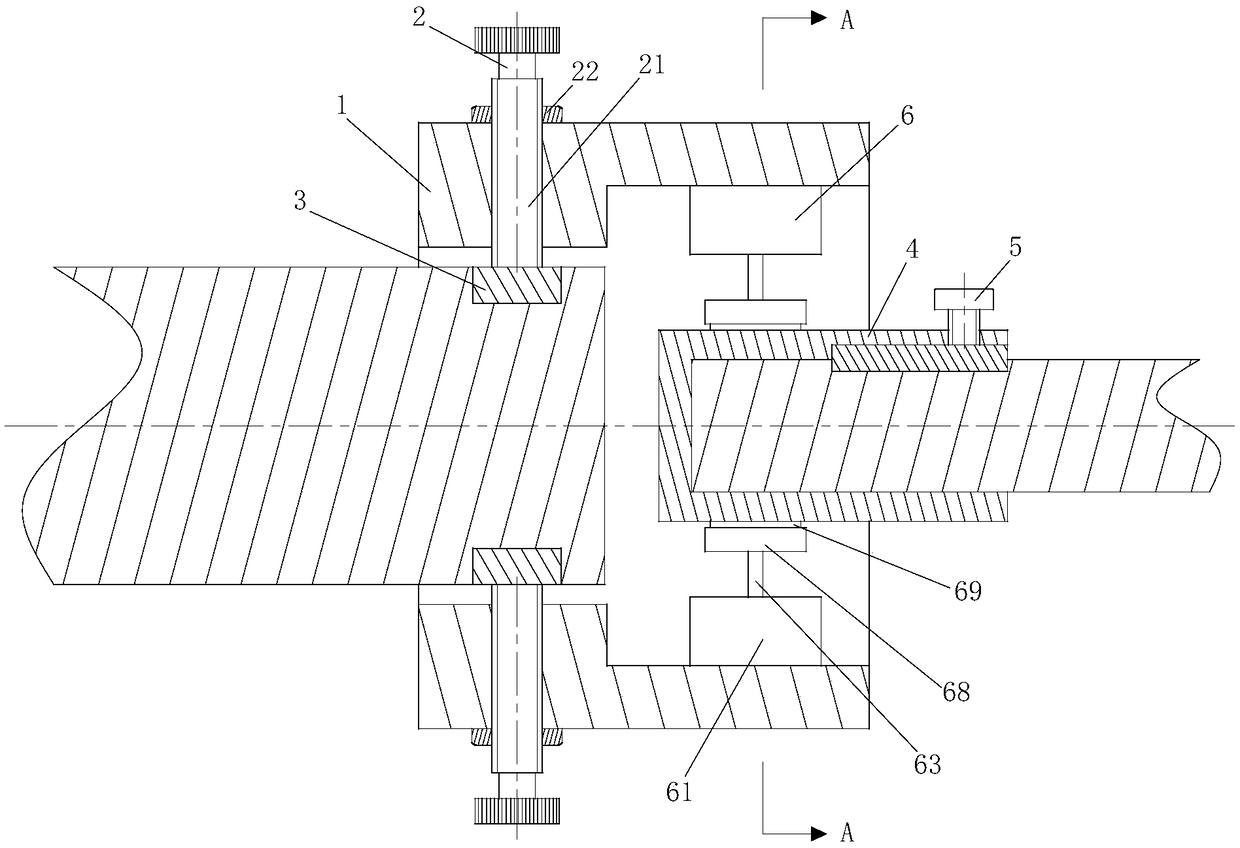

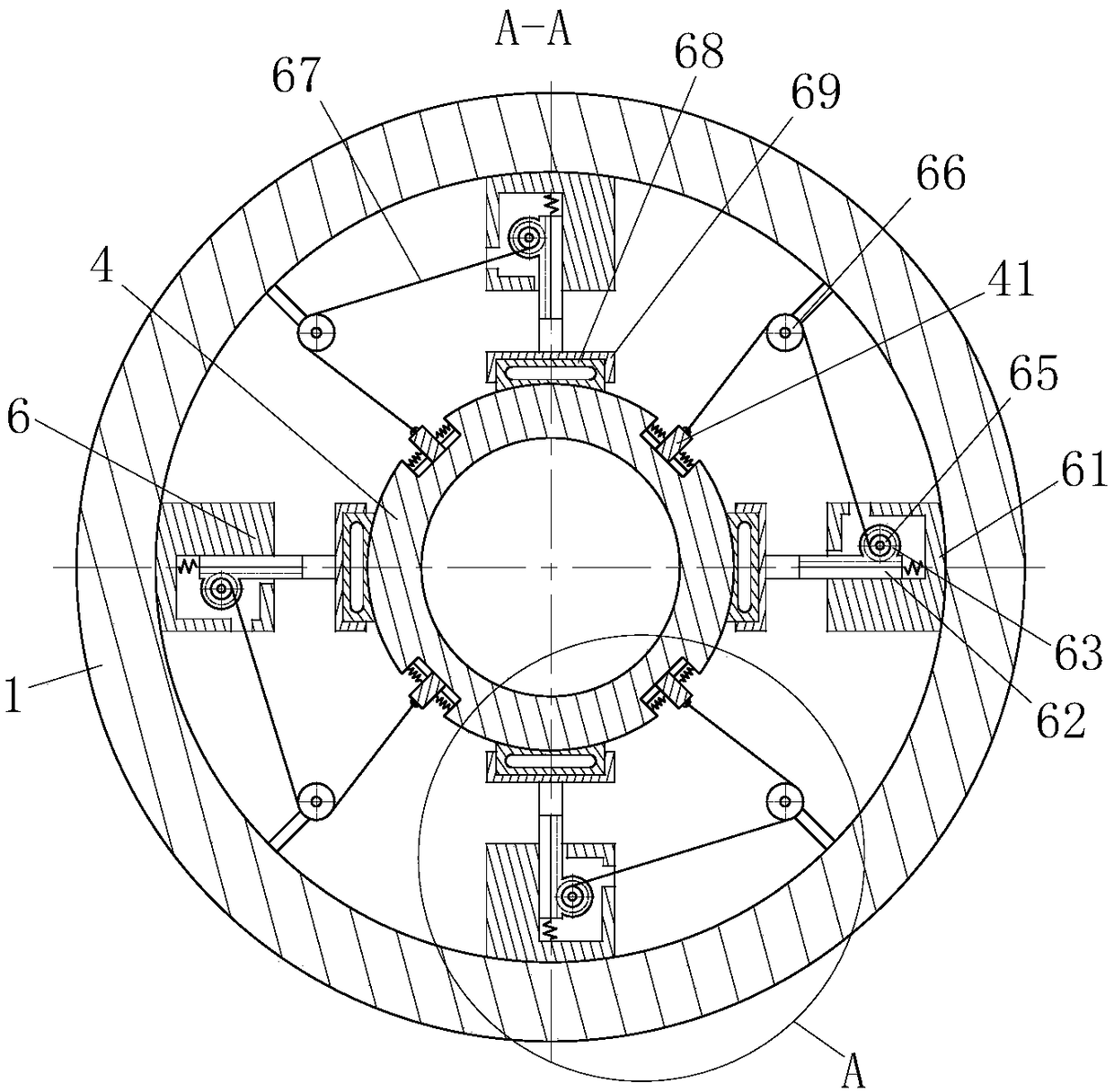

[0030] Wherein, the adjustable shaft coupling described in step 3 includes a main body 1, an adjusting member 2, a shaft coupling key 3, a shaft sleeve 4, a fastening bolt 5 and a locking me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com