Mechanical vegetable and vine type plant chopping machine

A mechanical shredder technology, applied in metal processing and other directions, can solve the problems of not being able to slice at one time, different uniformity, time-consuming and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0028] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

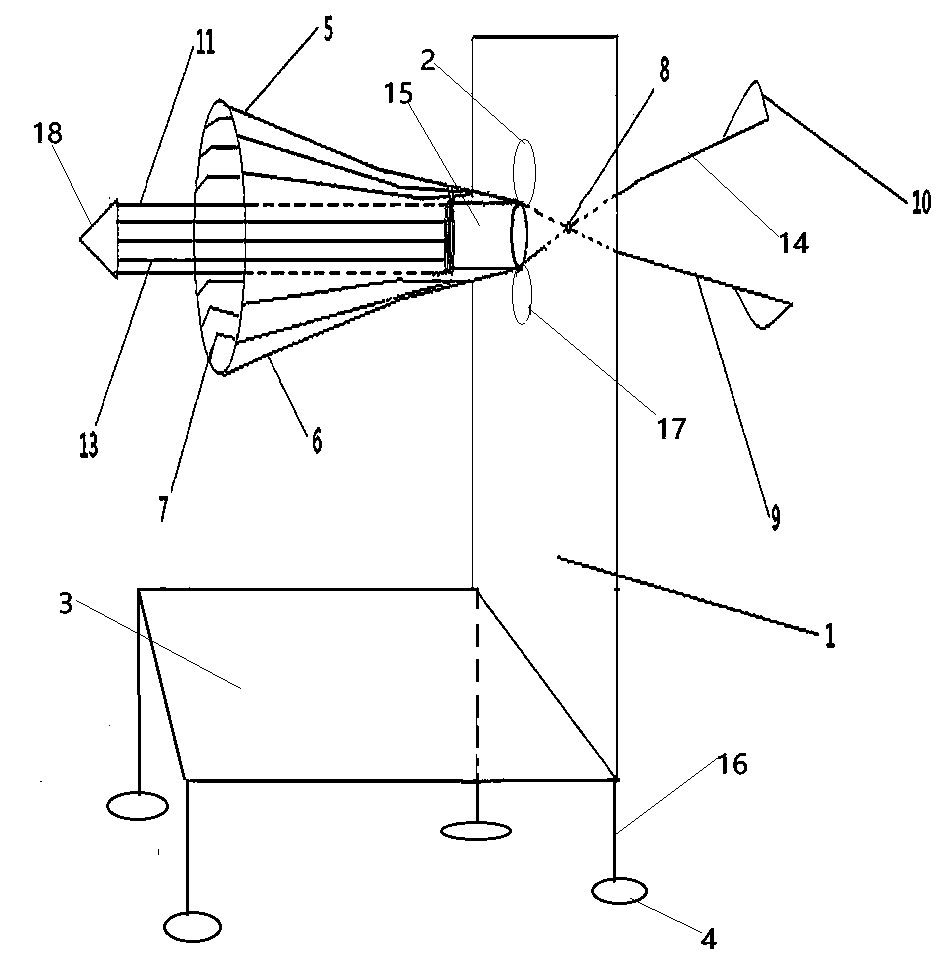

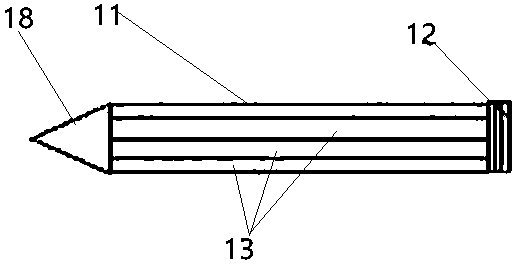

[0029] Such as Figure 1-Figure 4 As shown, the present invention includes a vertical plate, a movable hole one, a horizontal plate, a suction cup, a cutting part one, a cutting part two, a cutting blade, a rivet, a rod one, a handle, a central column, a connecting column, a groove, a rod two, a fixing Seat, plate leg, movable hole two, pointed cone, wherein, the vertical plate and the horizontal plate are all rectangular, and the vertical plate is vertically arranged on the right side above the horizontal plate; the bottom end of the plate leg is provided with a As for the suction cup, f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap