Treatment method and treatment device of high-salinity and high-COD (Chemical Oxygen Demand) organic wastewater

A technology of organic wastewater and treatment method, which is applied in the field of organic wastewater treatment, can solve the problems of inorganic salt pollution, difficulty in meeting discharge requirements, inability to oxidize and degrade organic matter, etc., and achieve the effects of recycling, low treatment cost and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

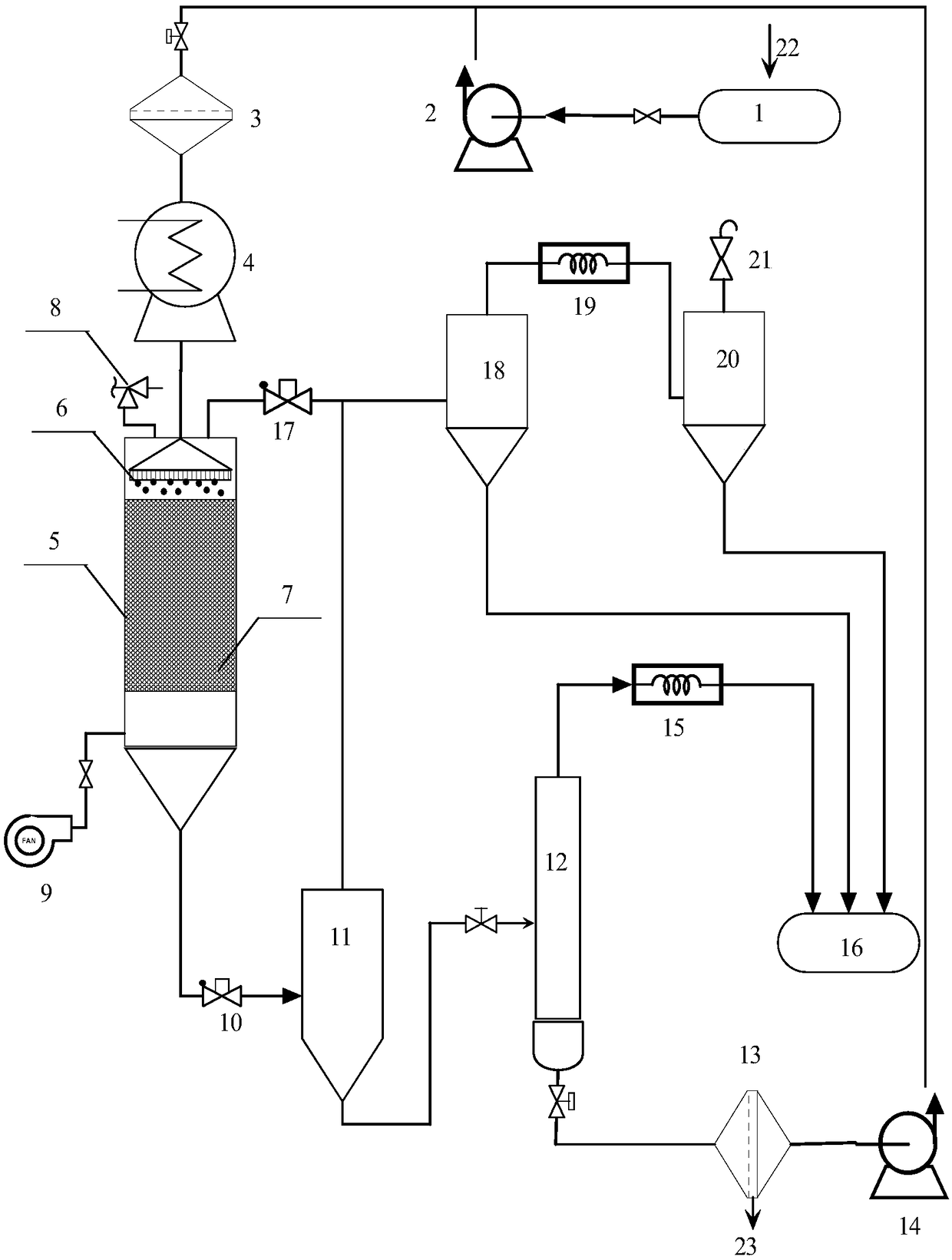

Method used

Image

Examples

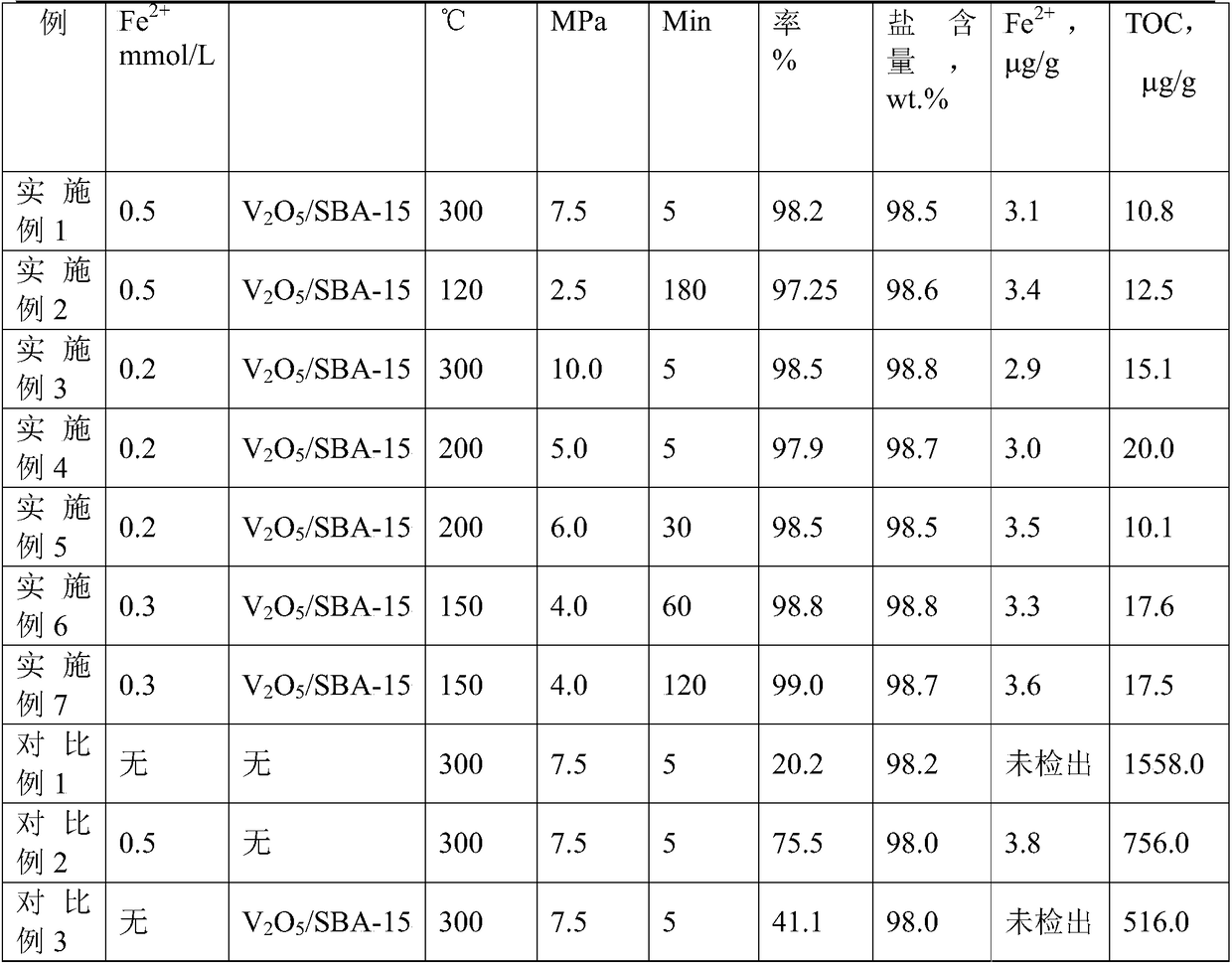

Embodiment 1

[0036] (1) Take high-salt and high-COD organic wastewater (NaCl content 19.0wt.%, COD: 20000mg / L) and add it to the wastewater storage tank, add anhydrous ferrous chloride catalyst and stir evenly, and Fe in the organic wastewater 2+ The molar concentration is 0.5mmol / L;

[0037] (2) Preheat to 300 °C, enter the device with V 2 O 5 In the fixed bed reactor of / SBA-15 catalyst, it reacts with oxygen; the reaction temperature is controlled to be 300°C, the reaction pressure is 7.5MPa, the residence time is 5min, and the flow rate of the waste water is 200ml / min;

[0038] (3) Sampling and analysis at the outlet of the fixed-bed reactor, then entering the flash evaporation device, cooling, and centrifuging out the solid salt NaCl through the desalting filter, and the centrifuged concentrated solution is returned to the filter device, then enters the preheating device, and is applied to In the process, the recycling of catalytic oxidation assistants is realized.

[0039] After t...

Embodiment 2

[0041] (1) Take high-salt and high-COD organic wastewater (NaCl content 24.1wt.%, COD: 20000mg / L) and add it to the wastewater storage tank, add anhydrous ferrous chloride catalyst and stir evenly, and Fe in the organic wastewater 2+ The molar concentration is 0.5mmol / L;

[0042] (2) Preheat to 120°C, enter the device with V 2 O 5 In the fixed bed reactor of / SBA-15 catalyst, it reacts with oxygen; the reaction temperature is controlled to be 120°C, the reaction pressure is 2.5MPa, the residence time is 180min, and the flow rate of the waste water is 5.6ml / min;

[0043] (3) Sampling and analysis at the outlet of the fixed-bed reactor, then entering the flash evaporation device, cooling, and centrifuging out the solid salt NaCl through the desalting filter, and the centrifuged concentrated solution is returned to the filter device, then enters the preheating device, and is applied to In the process, the recycling of catalytic oxidation assistants is realized.

[0044] After ...

Embodiment 3

[0046] (1) Take high-salt and high-COD organic wastewater (KCl content 10.0wt.%, COD: 10000mg / L) and add it to the wastewater storage tank, add anhydrous ferrous chloride catalyst and stir evenly, and Fe in the organic wastewater 2+ The molar concentration of 0.2mmol / L;

[0047] (2) Preheat to 300 °C, enter the device with V 2 O 5 In the fixed bed reactor of / SBA-15 catalyst, it reacts with oxygen; the reaction temperature is controlled to be 300°C, the reaction pressure is 10.0MPa, the residence time is 5min, and the flow rate of the waste water is 200ml / min;

[0048] (3) Sampling and analysis at the outlet of the fixed-bed reactor, then entering the flash evaporation device, cooling, and centrifuging the solid salt KCl through the desalting filter, the centrifuged concentrated solution is returned to the filter device, and then enters the preheating device, which is applied to In the process, the recycling of catalytic oxidation assistants is realized.

[0049] After test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com