Self-leveling self-compacting concrete and preparation technology thereof

A concrete and self-leveling technology, applied in the field of concrete, can solve the problems of easy cracking of concrete, restricted use and development, difficult to form self-compacting, etc., so as to improve self-compacting and self-leveling properties, and good fluidity and self-compacting properties. , Good carbonization resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

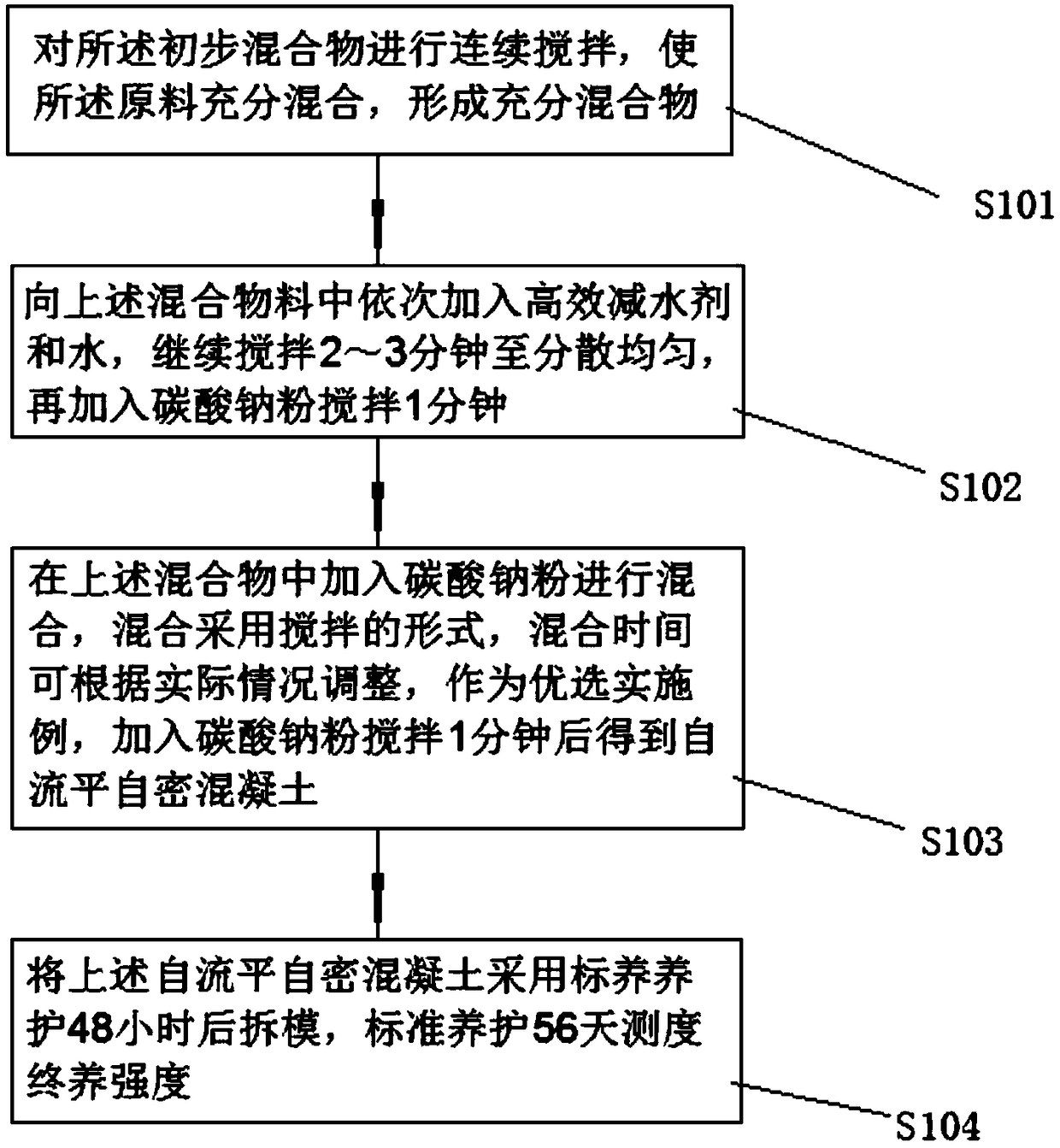

Method used

Image

Examples

Embodiment 1

[0049] A self-leveling self-compacting concrete, the self-leveling self-compacting concrete is made of the following raw materials in parts by mass:

[0050]400kg of cement, 172kg of powder, 1000kg of sand, 20kg of lime powder, 15kg of admixture, 3.4kg of superplasticizer, 95kg of water, 200kg of cement and 60kg of steel fiber.

[0051] Wherein, the sand includes the following raw materials: 600kg of fine aggregate and 400kg of coarse aggregate, the particle size of the fine aggregate is below 4.75mm, and the particle size of the coarse aggregate is greater than 5mm.

[0052] The coarse aggregate includes the following raw materials: 210kg of crushed stones and 190kg of pebbles, the crushed stones are made of natural rocks, pebbles or mine waste rocks through mechanical crushing and screening, and rock particles with a particle size greater than 5mm. Pebbles are rock particles with a particle size greater than 5mm formed by natural weathering, water flow handling, sorting, and...

Embodiment 2

[0063] A self-leveling self-compacting concrete, the self-leveling self-compacting concrete is made of the following raw materials in parts by mass:

[0064] 475kg of cement, 182.5kg of powder, 1050kg of sand, 25kg of lime powder, 17kg of admixture, 4.5kg of superplasticizer, 100kg of water, 230kg of cement and 62kg of steel fiber.

[0065] Wherein, the sand includes the following raw materials: 625 kg of fine aggregate and 425 kg of coarse aggregate, the particle size of the fine aggregate is below 4.75 mm, and the particle size of the coarse aggregate is greater than 5 mm.

[0066] The coarse aggregate includes the following raw materials: 225kg of crushed stones and 200kg of pebbles, the crushed stones are made of natural rocks, pebbles or mine waste rocks through mechanical crushing and screening, and rock particles with a particle size greater than 5mm. Pebbles are rock particles with a particle size greater than 5mm formed by natural weathering, water flow handling, sort...

Embodiment 3

[0077] A self-leveling self-compacting concrete, the self-leveling self-compacting concrete is made of the following raw materials in parts by mass:

[0078] 550kg of cement, 193kg of powder, 1100kg of sand, 30kg of lime powder, 20kg of admixture, 5.7kg of superplasticizer, 105kg of water, 260kg of cement and 65kg of steel fiber.

[0079] Wherein, the sand includes the following raw materials: 650 kg of fine aggregate and 450 kg of coarse aggregate, the particle size of the fine aggregate is below 4.75 mm, and the particle size of the coarse aggregate is greater than 5 mm.

[0080] The coarse aggregate includes the following raw materials: 245kg of crushed stones and 205kg of pebbles, the crushed stones are made of natural rocks, pebbles or mine waste rocks through mechanical crushing and screening, and rock particles with a particle size greater than 5mm. Pebbles are rock particles with a particle size greater than 5mm formed by natural weathering, water flow handling, sortin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com