Method to precisely control iron-loading capacity of iron protein succinylate

A technology of iron protein succinate and precise control, which is applied in the field of medicine, can solve the problems of large measurement work, tedious work, and the inability to accurately quantify the iron content of iron protein succinate, and achieve the effect of stable quality, simple process, and avoiding measurement work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

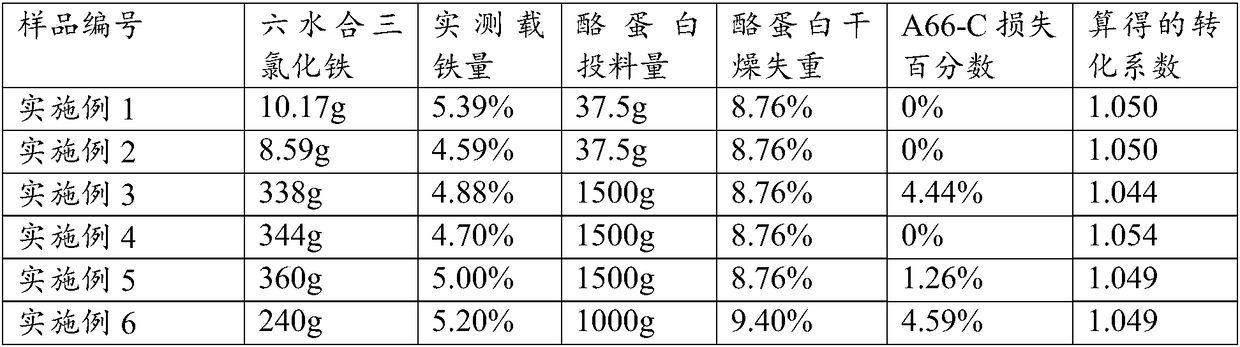

Examples

Embodiment 1

[0071] Disperse 37.5g of casein (loss on drying: 8.76%) in 250g of purified water, add 8.5g of 4N sodium hydroxide solution dropwise after raising the temperature to 60°C to keep the system pH=7-9 to fully dissolve the casein, then divide more Add 5.5g of succinic anhydride in batches and at the same time dropwise add 30.0g of 4N sodium hydroxide solution to keep the system pH=5-7. The hydrochloric acid solution maintains the pH of the system at 2.0-3.0 to precipitate solids. After centrifugation, the obtained solids are added to an appropriate amount of 250 g of purified water, beaten at room temperature for 1-3 hours, and then centrifuged to obtain 240 g of wet succinyl casein.

[0072] Take 240g of the above wet product of succinyl casein and disperse it in 500g of purified water. After raising the temperature to 60°C, add 41.5g of 4N sodium hydroxide solution dropwise to maintain the system pH=7-9 to fully dissolve the succinyl casein, and then filter to remove a small amou...

Embodiment 2

[0075] Disperse 37.5g of casein (loss on drying: 8.76%) in 250g of purified water, add 8.5g of 4N sodium hydroxide solution dropwise after raising the temperature to 60°C to keep the system pH=7-9 to fully dissolve the casein, then divide more Add 5.5g of succinic anhydride in batches and at the same time dropwise add 30.0g of 4N sodium hydroxide solution to keep the system pH=5-7. The hydrochloric acid solution maintains the pH of the system at 2.0-3.0 to precipitate solids. After centrifugation, the obtained solids are added to an appropriate amount of 250 g of purified water, beaten at room temperature for 1-3 hours, and then centrifuged to obtain 240 g of wet succinyl casein.

[0076] Take 240g of the above wet product of succinyl casein and disperse it in 500g of purified water. After raising the temperature to 60°C, add 41.5g of 4N sodium hydroxide solution dropwise to maintain the system pH=7-9 to fully dissolve the succinyl casein, and then filter to remove a small amou...

Embodiment 3

[0079] Disperse 1.50kg of casein (loss on drying: 8.76%) in 10.00kg of purified water, add 0.34kg of 4N sodium hydroxide solution dropwise after heating up to 60°C to keep the system pH=7-9 to fully dissolve the casein, then divide Add 0.22kg of succinic anhydride in multiple batches and dropwise add 1.16kg of 4N sodium hydroxide solution to keep the pH of the system at 5-7. 4N hydrochloric acid solution kept the pH of the system at 2.0-3.0 to precipitate solids. After centrifugation, the resulting solids were added to an appropriate amount of 16.00 kg of purified water, beaten at room temperature for 1-3 hours, and then centrifuged to obtain 4.48 kg of wet succinyl casein.

[0080] Take 4.48kg of the above wet product of succinyl casein and disperse it in 10.00kg of purified water. After raising the temperature to 60°C, add 0.79kg of 4N sodium hydroxide solution dropwise to keep the system pH=7-9 to fully dissolve the succinyl casein, and then remove it by filtration. A small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com