Method for efficiently coagulating natural latex under assistance effects of microwave fields

A technology of natural rubber latex and microwave field, which is applied in the field of natural rubber processing, can solve the problems of short microwave coagulation time, low work efficiency, low modulus stress and tensile strength, slow rubber vulcanization rate, etc. The effect of reducing the amount of work and increasing work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

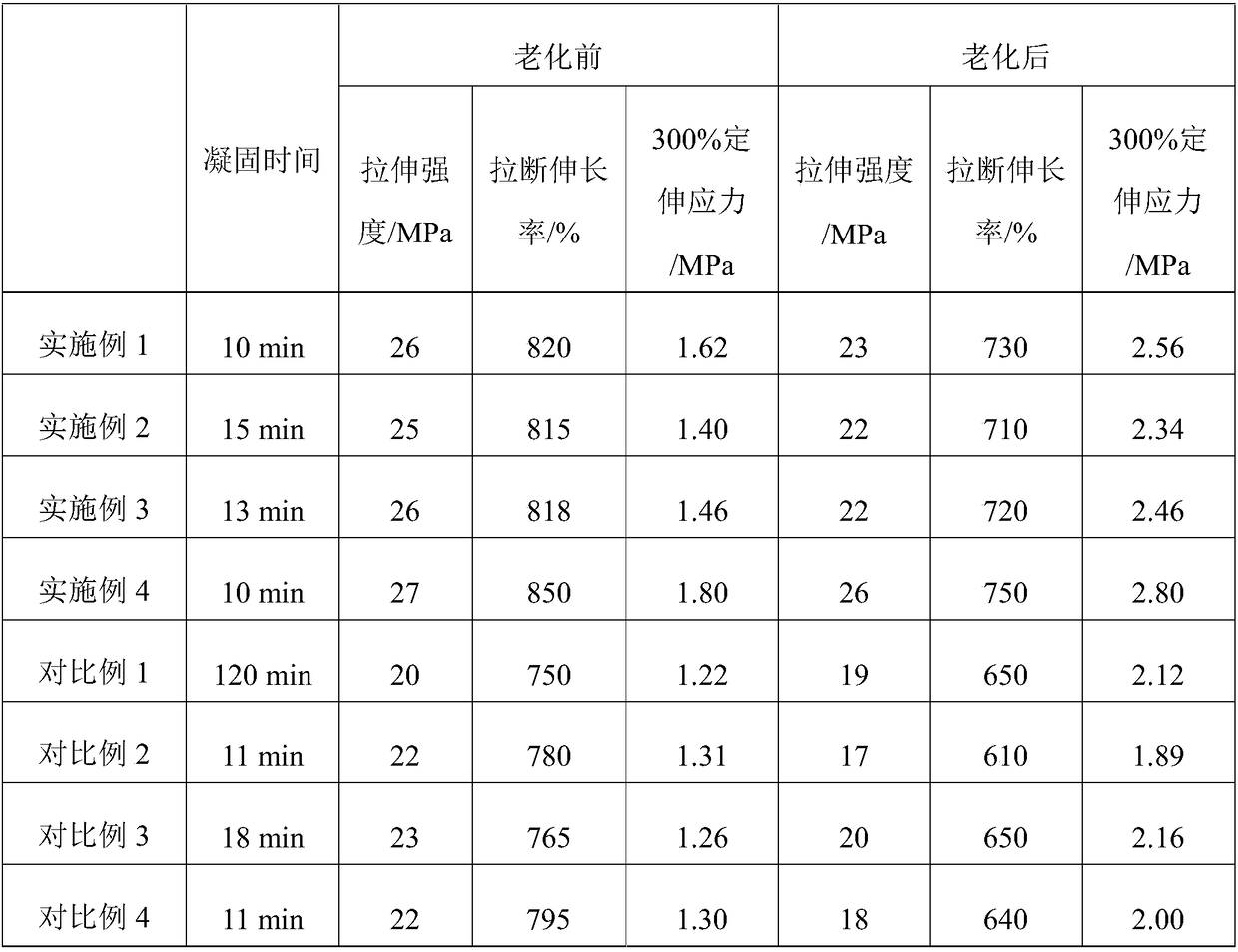

Examples

Embodiment 1

[0023] A method for coagulating natural rubber latex efficiently with the assistance of a microwave field, the specific steps are:

[0024] Get 100g of fresh latex (the content of dry glue is 25%) and add it to the ceramic tray. The thickness of the latex is 12-18mm, then add 12.5g of acetic acid solution (mass fraction 10%) in the tray, put it into the microwave equipment, and the microwave frequency is 2450MHz ( Medium heat) heating for 10min, causing the latex to completely coagulate.

Embodiment 2

[0026] A method for coagulating natural rubber latex efficiently with the assistance of a microwave field, the specific steps are:

[0027] Take 100g of fresh latex (the content of dry glue is 25%) and add it to the ceramic tray. The thickness of the latex is 12-18mm, then add 15g of acetic acid solution (mass fraction 2%) into the tray, and put it into the microwave equipment. The microwave frequency is 2000MHz (medium Fire) heated for 15min, causing the latex to completely coagulate.

Embodiment 3

[0029] A method for coagulating natural rubber latex efficiently with the assistance of a microwave field, the specific steps are:

[0030] Take 100g of fresh latex (the content of dry glue is 44%) and add it to the ceramic tray. The thickness of the latex is 12-18mm, then add 10g of acetic acid solution (mass fraction 10%) in the tray, put it into the microwave equipment, and the microwave frequency is 3000MHz (medium Fire) heated for 13min, causing the latex to completely coagulate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| 300% modulus stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com