Preparation method of three-dimensional reticular MWCNTs/NiFe2O4 (multi-wall carbon nanotube/nickel ferrite) composite wave absorbing material

A technology of multi-walled carbon nanotubes and composite absorbing materials, applied in chemical instruments and methods, magnetic field/electric field shielding, electrical components, etc., can solve the problems of narrow absorption frequency band, limited application, high density, etc., and achieve enhanced attenuation ability, Easy operation and low density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Take a 100mL beaker, add 30mL ethylene glycol (EG) and 0mg MWCNTs, and sonicate for 30min;

[0030] 2. Add 0.54g ferric chloride hexahydrate (FeCl 3 ·6H 2 O) and 0.21g nickel chloride hexahydrate (NiCl 2 ·6H 2 O), vigorously stirred for 20min. Among them, Fe 3+ with you 2+ The molar ratio satisfies n Fe3+ :n Ni2+ =2:1;

[0031] 3. Add 2.37g of anhydrous ammonium acetate (NH 4 Ac), vigorously stirred for 30min;

[0032] 4. Pour the mixed dispersion liquid into a 50mL reactor, and react with solvent heat at 200°C for 12 hours;

[0033] 5. After the reaction, cool to room temperature, magnetically separate, and wash with deionized water and absolute ethanol several times to make the pH of the product reach neutral;

[0034] 6. Put it into a vacuum drying oven, dry at 50°C for 24 hours, and grind to obtain the final product, which is recorded as S1.

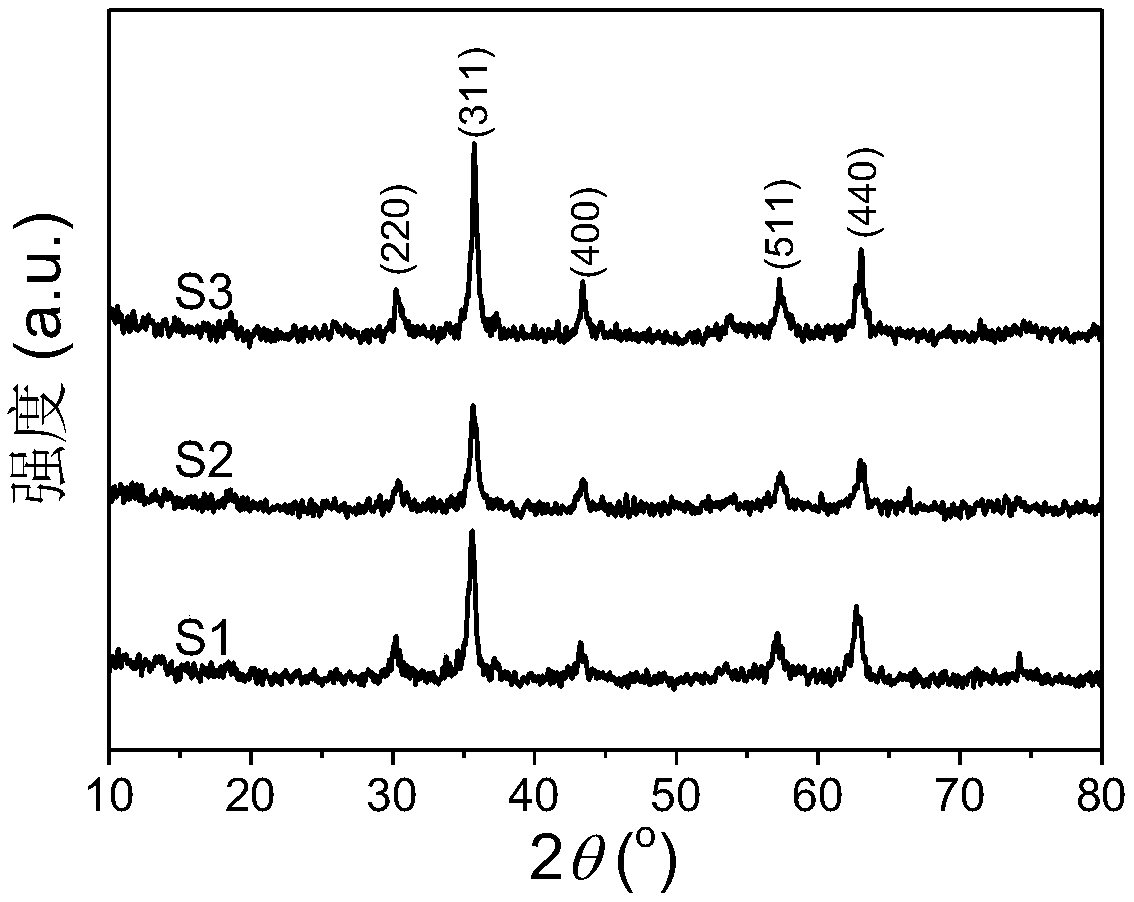

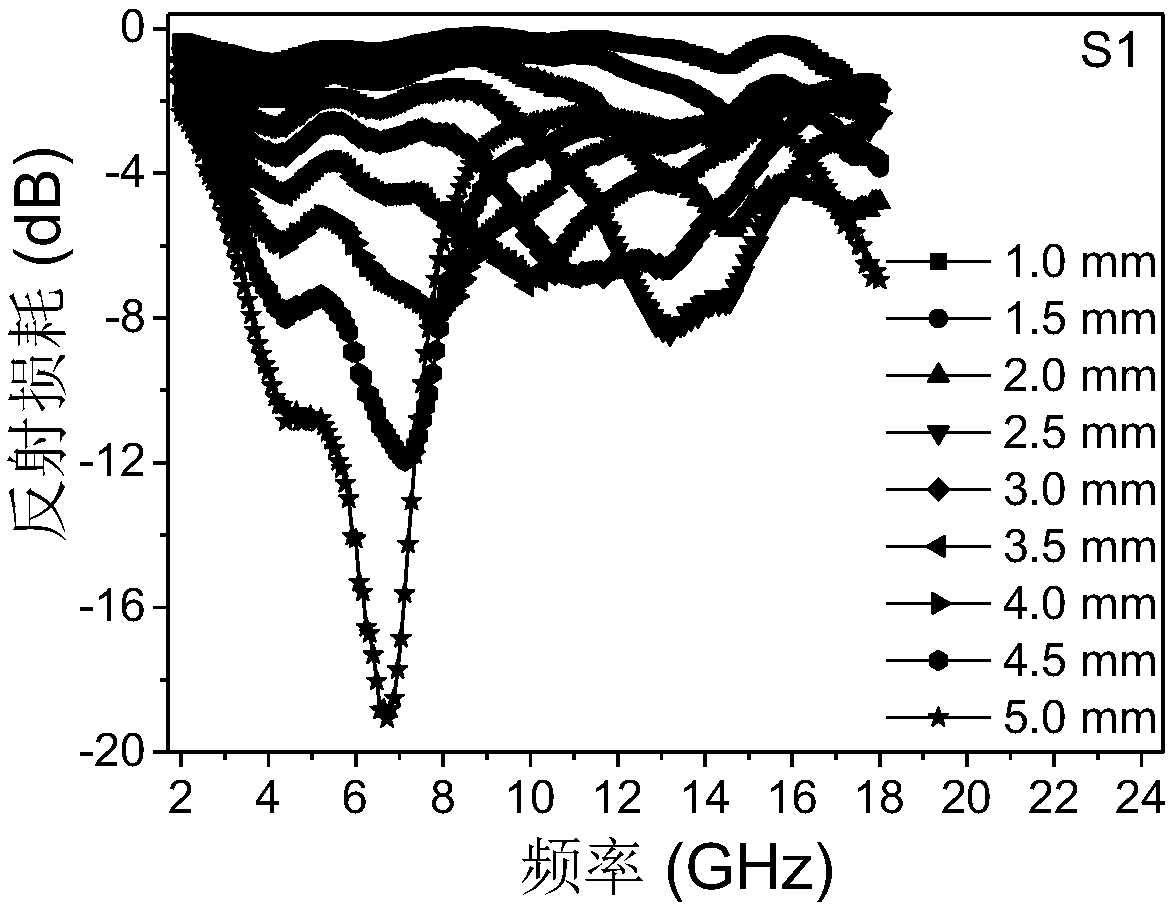

[0035] The XRD spectrogram of embodiment 1 product sees figure 1 . The powder product and paraffin in Examp...

Embodiment 2

[0037] 1. Take a 100mL beaker, add 30mL ethylene glycol (EG) and 10mg MWCNTs, and sonicate for 30min;

[0038] 2. Add 0.54g ferric chloride hexahydrate (FeCl 3 ·6H 2 O) and 0.21g nickel chloride hexahydrate (NiCl 2 ·6H 2 O), vigorously stirred for 20min. Among them, Fe 3+ with you 2+ The molar ratio satisfies n Fe3+ :n Ni2+ =2:1;

[0039] 3. Add 2.37g of anhydrous ammonium acetate (NH 4 Ac), vigorously stirred for 30min;

[0040] 4. Pour the mixed dispersion liquid into a 50mL reactor, and react with solvent heat at 200°C for 12 hours;

[0041] 5. After the reaction, cool to room temperature, magnetically separate, and wash with deionized water and absolute ethanol several times to make the pH of the product reach neutral;

[0042] 6. Put it into a vacuum drying oven, dry at 50°C for 24 hours, and grind to obtain the final product, which is recorded as S2.

[0043] The XRD spectrum pattern of embodiment 2 product sees figure 1. The powder product and paraffin in ...

Embodiment 3

[0045] 1. Take a 100mL beaker, add 30mL ethylene glycol (EG) and 20mg MWCNTs, and sonicate for 30min;

[0046] 2. Add 0.54g ferric chloride hexahydrate (FeCl 3 ·6H 2 O) and 0.21g nickel chloride hexahydrate (NiCl 2 ·6H 2 O), vigorously stirred for 20min. Among them, Fe 3+ with you 2+ The molar ratio satisfies n Fe3+ :n Ni2+ =2:1;

[0047] 3. Add 2.37g of anhydrous ammonium acetate (NH 4 Ac), vigorously stirred for 30min;

[0048] 4. Pour the mixed dispersion liquid into a 50mL reactor, and react with solvent heat at 200°C for 12 hours;

[0049] 5. After the reaction, cool to room temperature, magnetically separate, and wash with deionized water and absolute ethanol several times to make the pH of the product reach neutral;

[0050] 6. Put it into a vacuum drying oven, dry at 50°C for 24 hours, and grind to obtain the final product, which is recorded as S3.

[0051] The XRD spectrum pattern of embodiment 3 product sees figure 1 . The powder product and paraffin in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com