Variable-viscosity agent for alcohol-based acid liquor and preparation method of variable-viscosity agent

An alcohol-based acid and adhesive technology, which is applied in the directions of chemical instruments and methods, drilling compositions, etc., can solve problems such as difficulty in using water-soluble diverting acid, and achieve the effects of avoiding formation damage, low production cost, and easy acquisition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

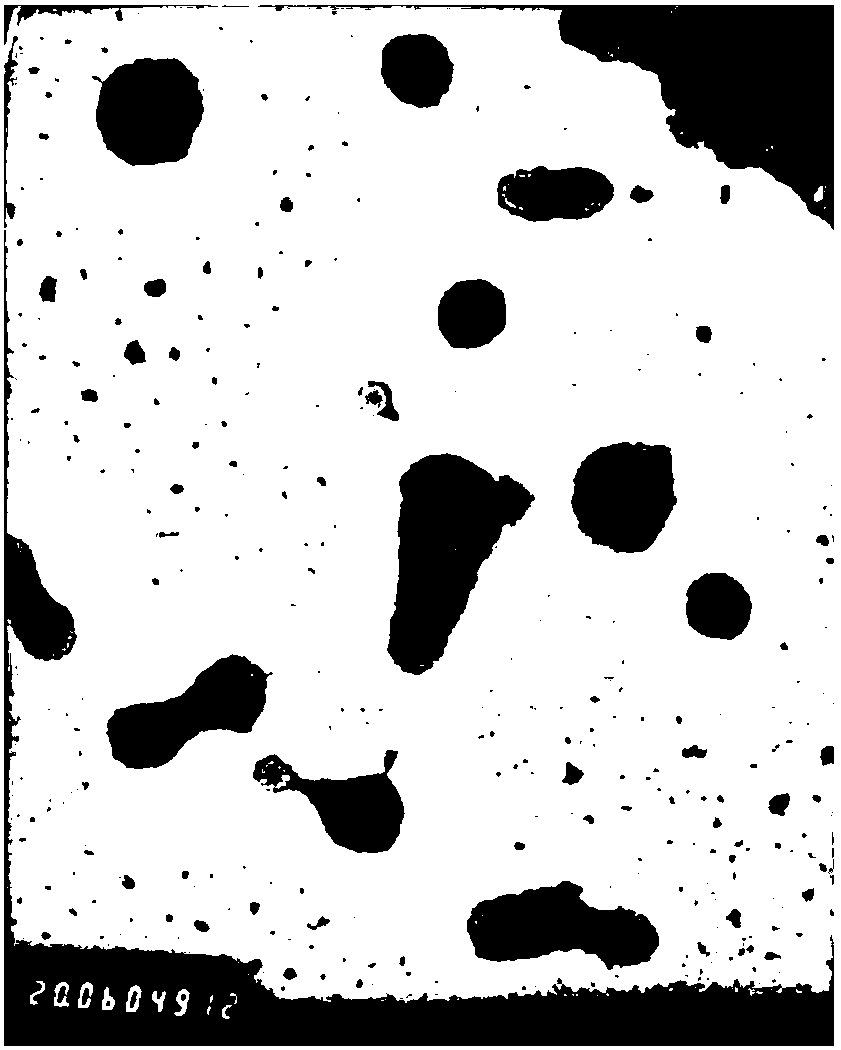

Image

Examples

preparation example Construction

[0032] In the first aspect, an embodiment of the present invention provides a method for preparing a viscosity-increasing agent for alcohol-based acid liquid, the method for preparing the viscosity-increasing agent comprising:

[0033] Step 1, using unsaturated carboxylic acid and / or its salt monomer, unsaturated sulfonic acid and / or its salt monomer and acrylate monomer as raw materials to carry out polymerization reaction to obtain soap-free latex;

[0034] Step 2, mixing the soap-free latex and saturated alcohol evenly to obtain a viscous agent;

[0035] The mass ratio of acrylate monomer, unsaturated carboxylic acid and / or its salt monomer, and unsaturated sulfonic acid and / or its salt monomer is (80-95):(5-20):(0 -5);

[0036] The volume ratio of soap-free latex to saturated alcohol is 1:1-1:4.

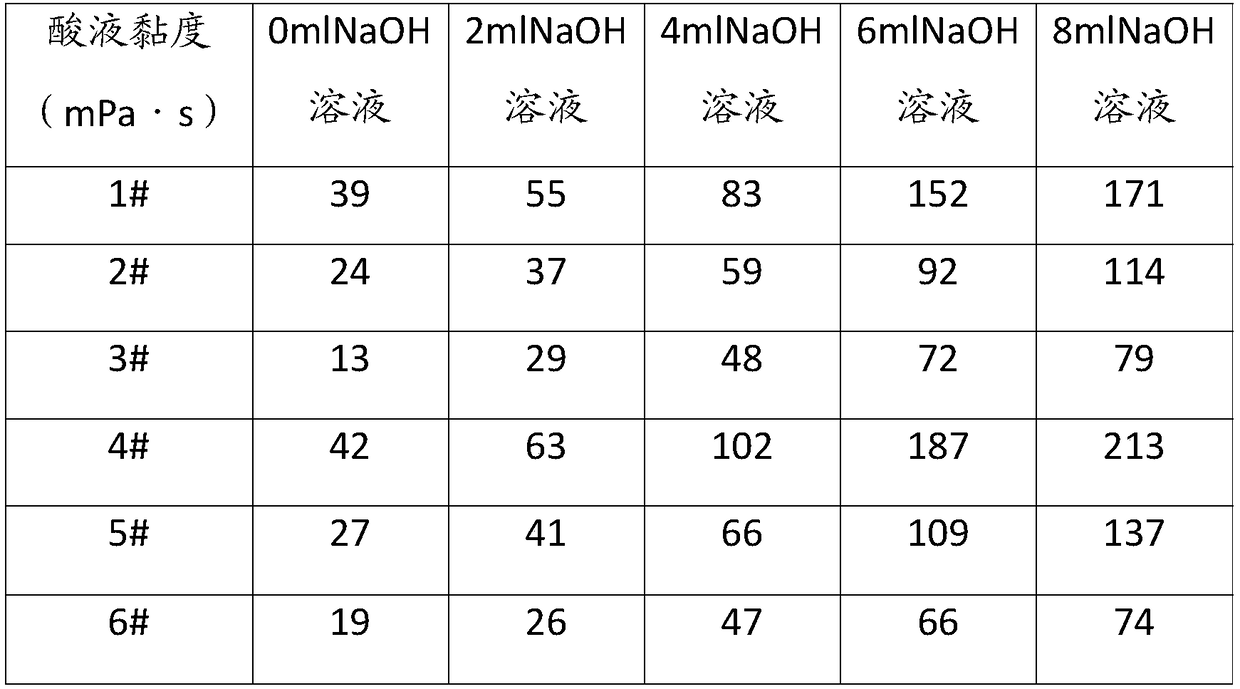

[0037] The viscosity of the acid solution system of the viscosifying agent provided by the embodiments of the present invention can increase with the increase of the pH value o...

Embodiment 1

[0063] The present embodiment provides a kind of soap-free latex, and this soap-free latex is prepared by following method:

[0064] Step 1. Dissolve 0.27g of potassium persulfate, 7.5g of sodium acrylate, and 2.5g of 2-acrylamido-2-methylpropanesulfonate monomer into 10g of water, and mix uniformly to obtain the first mixture;

[0065] Under the condition of 65°C, uniformly mix 25g of methyl methacrylate monomer and 15g of ethyl methacrylate monomer, and add dropwise to 50g of water with the first mixture, and control the dropping end point to reach at the same time, to obtain the second mixture;

[0066] Step 2. The temperature of the second mixture is raised to 82° C. and kept for 0.4 h to obtain a soap-free latex; and the average particle diameter of the soap-free latex is 120 nm.

Embodiment 2

[0068] The present embodiment provides a kind of soap-free latex, and this soap-free latex is prepared by following method:

[0069] Step 1. Dissolve 0.33g of potassium persulfate, 7.5g of sodium acrylate monomer, and 2.5g of 2-acrylamido-2-methylpropanesulfonate monomer into 10g of water, and mix uniformly to obtain the first mixture;

[0070] Under the condition of 65°C, uniformly mix 25g of methyl methacrylate monomer and 15g of ethyl methacrylate monomer, and add dropwise to 50g of water with the first mixture, and control the dropping end point to reach at the same time, to obtain the second mixture;

[0071] Step 2. The temperature of the second mixture is raised to 85° C. and kept warm for 0.4 h to obtain a soap-free latex; and the average particle size of the soap-free latex is 90 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com