Acid-sensitive variable-viscosity mixed surfactant

A technology of surfactant and active agent, applied in the field of acid-sensitive viscous mixed surfactant, can solve the problems of high cost, high concentration of viscoelastic surfactant, application limitation, etc., and achieve increased flow resistance and uniform acidification effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

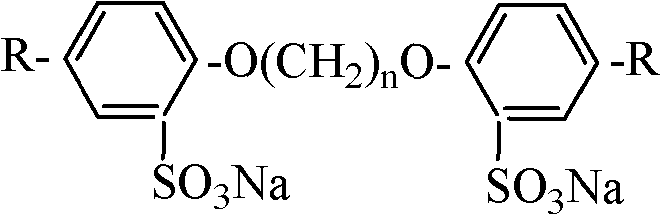

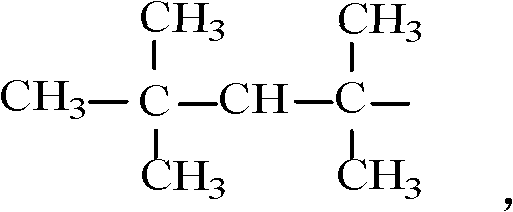

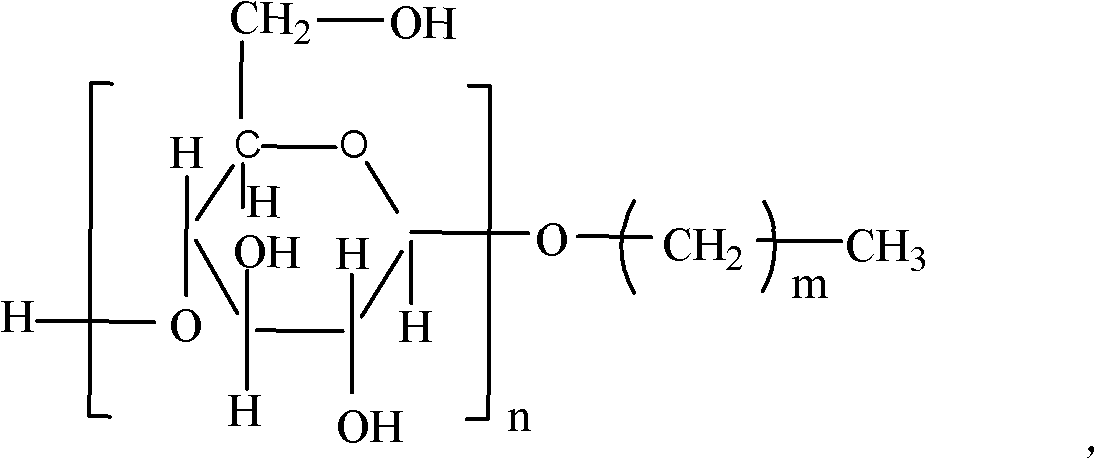

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: According to the mass ratio of sulfonate gemini surfactant and alkyl glycoside nonionic surfactant is 4: 1, 3: 1, 2: 1, 1: 1, 1: 2, 1: 3 and 1 : 4 prepare the mixed surfactant system that the total mass concentration of surfactant is 2% respectively, then add the anhydrous calcium chloride that mass concentration is 2% respectively in each system, measure different shear rates under the condition of 60 ℃ Viscosity, the results are shown in Table 1. Under the mass ratio of 1:4~4:1, the mixed surfactant has higher viscosity, and the viscosity is far greater than the viscosity of a single surfactant solution, and when the mass ratio is 2:1, the viscosity of the mixed surfactant Best for thickening.

[0030] Table 1 Viscosity of acid-sensitive mixed surfactant system

[0031]

Embodiment 2

[0032] Embodiment 2: preparation hydrochloric acid mass concentration is respectively the mass ratio of sulfonate gemini surfactant and alkyl glycoside nonionic surfactant of 1%, 0.5%, 0.1%, 0.05%, 0.01%, 0.005% and 0% It is a 2: 1 mixed surfactant solution system, the total surfactant mass concentration of the system is 1.5%, and then anhydrous calcium chloride with a mass concentration of 2% is added to each system, and measured at 60°C Viscosities at different shear rates are shown in Table 2. The viscosity of the mixed surfactant system increases with the decrease of acid mass concentration.

[0033] The influence of table 2 acid concentration on the viscosity of acid-sensitive mixed surfactant system

[0034]

Embodiment 3

[0035]Embodiment 3: preparation mass concentration is 1.5%, the mass ratio of sulfonate gemini surfactant and alkyl glycoside nonionic surfactant is the mixed surfactant solution system of 2: 1 and mass concentration is 2% anhydrous Calcium chloride solution, the viscosity of the solution system is very large, then add the volume ratio of 3% kerosene, the viscosity of the solution system obviously decreases after stirring, then add the volume ratio of 3% kerosene, the solution system viscosity is close to the viscosity of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com