Rapid neptunium separating method

A fast, organic-phase technology used in chemistry to solve problems such as slow separation rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

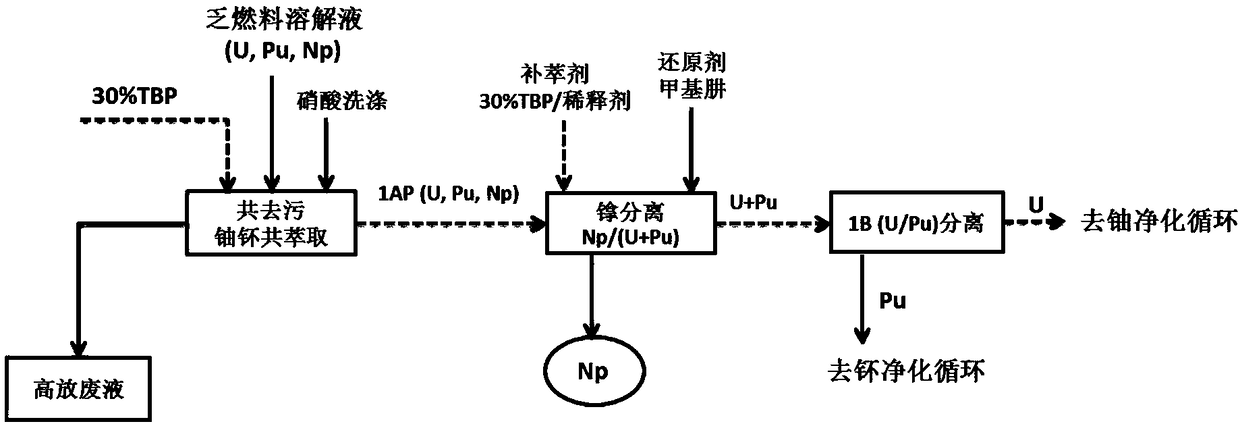

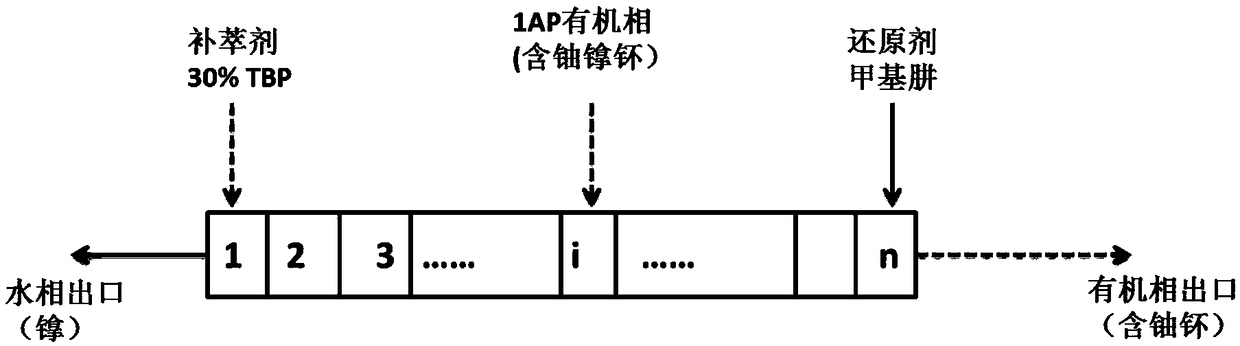

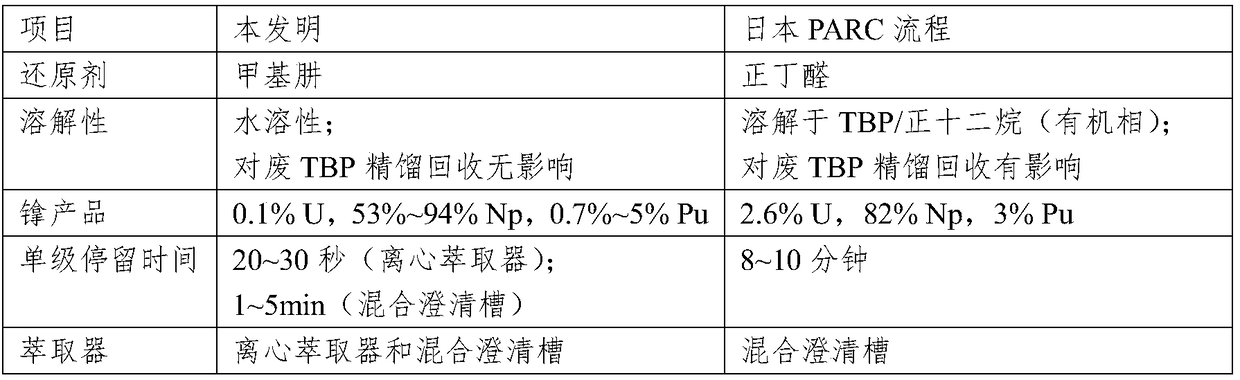

[0034] Schematic representation of fast separation of neptunium in the Purex flow process according to an embodiment of the present invention, such as figure 2 As shown, the neptunium is reductively stripped to the water phase by using a multi-stage countercurrent reduction stripping process, and the uranium and plutonium are retained in the organic phase to realize the separation and extraction of neptunium. The reducing agent methylhydrazine is added from the outlet of the organic phase, the outlet of the organic phase is the nth stage, n>2, the reducing agent is dissolving methylhydrazine in aqueous nitric acid solution, wherein the concentration of methylhydrazine is a, 0<a≤1.0 mol / L, the concentration of nitric acid is b, 0<b≤5.0mol / L, the flow ratio of adding reducing agent is: organic phase material solution containing uranium, neptunium and plutonium / reducing agent=1 / 10~1 / 0.1. The supplementary extraction agent is added from the outlet of the water phase, the outlet o...

Embodiment 2

[0036] According to another embodiment of the present invention, the same as embodiment 1, the difference is that the multistage countercurrent reduction and stripping is that the reducing agent methylhydrazine is added from the nth stage water phase inlet of the multistage centrifugal extractor, n >2, the supplementary extraction agent is added from the first-stage organic phase inlet of the multi-stage centrifugal extractor, and the organic phase feed solution containing uranium, neptunium and plutonium is added from the i-stage of the multi-stage centrifugal extractor, 1<i<n.

Embodiment 3

[0038] According to an embodiment of the present invention, a 12-stage centrifugal extractor is used with a mixing chamber of 0.7 mL; a syringe pump of model MSP1-C1 is used as the liquid flow delivery device. Concentrated nitric acid, tributyl phosphate (TBP), and sodium nitrite are all national medicines, analytically pure; kerosene is hydrogenated kerosene; uranyl nitrate is analytically pure. Np(Ⅵ) solution: Neptunium nitrate solution was electrolyzed at a constant current, using an H-shaped glass electrolytic cell with a diaphragm, a platinum mesh as an anode, and a titanium sheet as a cathode, and the current density was controlled at 30mA cm-2 for electrolytic oxidation to prepare Np(Ⅵ) ) solution, Np(Ⅵ) is generated when the anode solution is rose red. Carry out spectral scanning on the anolyte, when there is an absorption peak at 1225nm (Np(Ⅵ)), and there is no absorption peak at 980nm (Np(V)) and 960nm (Np(Ⅳ)), the solution in the anode chamber is collected as Np(Ⅵ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com