Fire resistant and weather resistant steel with yield strength larger than or equal 690 MPa and used for welding structure and production method thereof

A technology of welded structure and yield strength, applied in the field of low-alloy steel manufacturing, can solve the problems of poor welding performance and corrosion resistance of construction steel

Inactive Publication Date: 2018-11-13

武汉钢铁有限公司

View PDF18 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0052] The present invention is described in detail below:

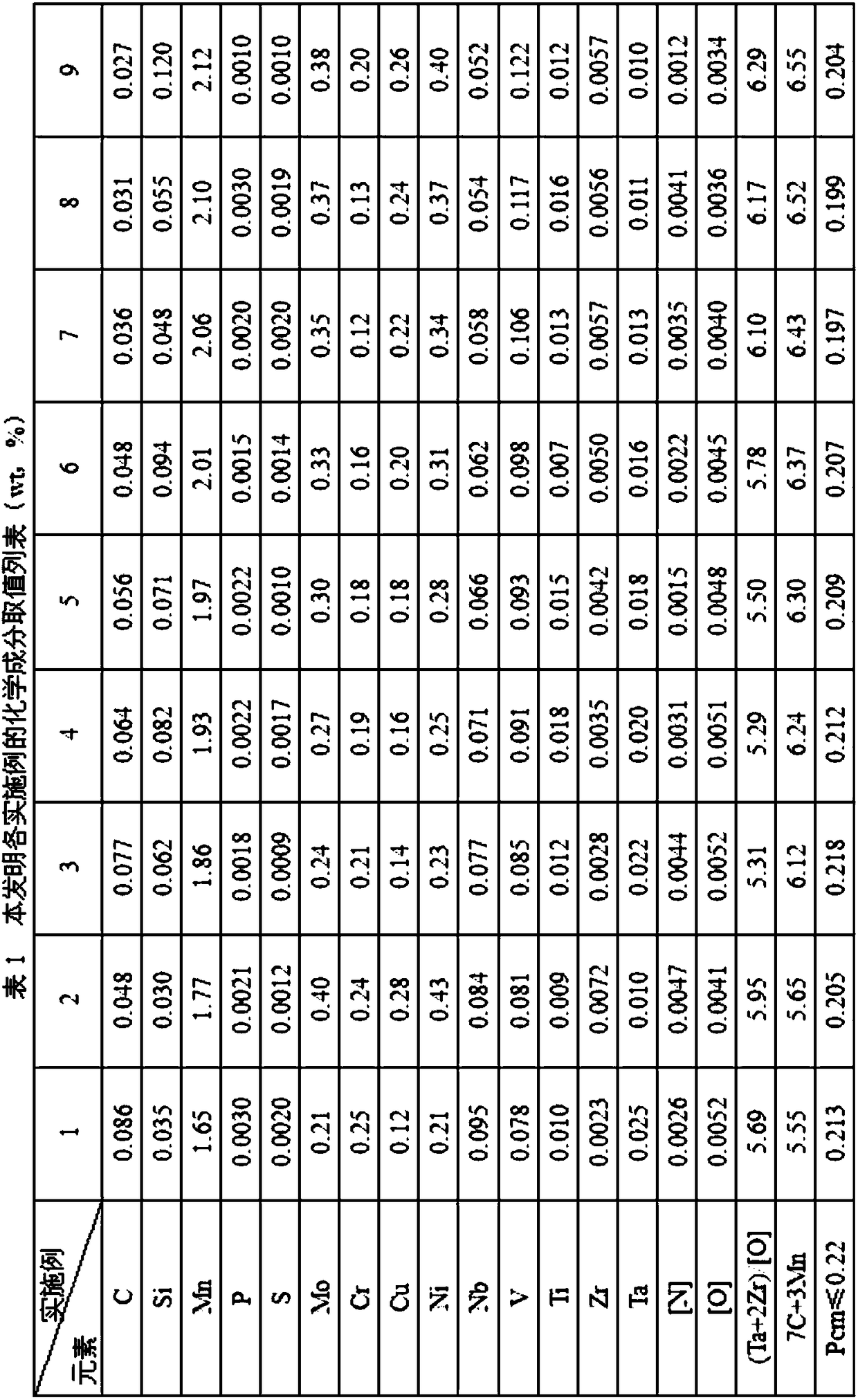

[0053]Table 1 is a list of chemical composition values of various embodiments of the present invention;

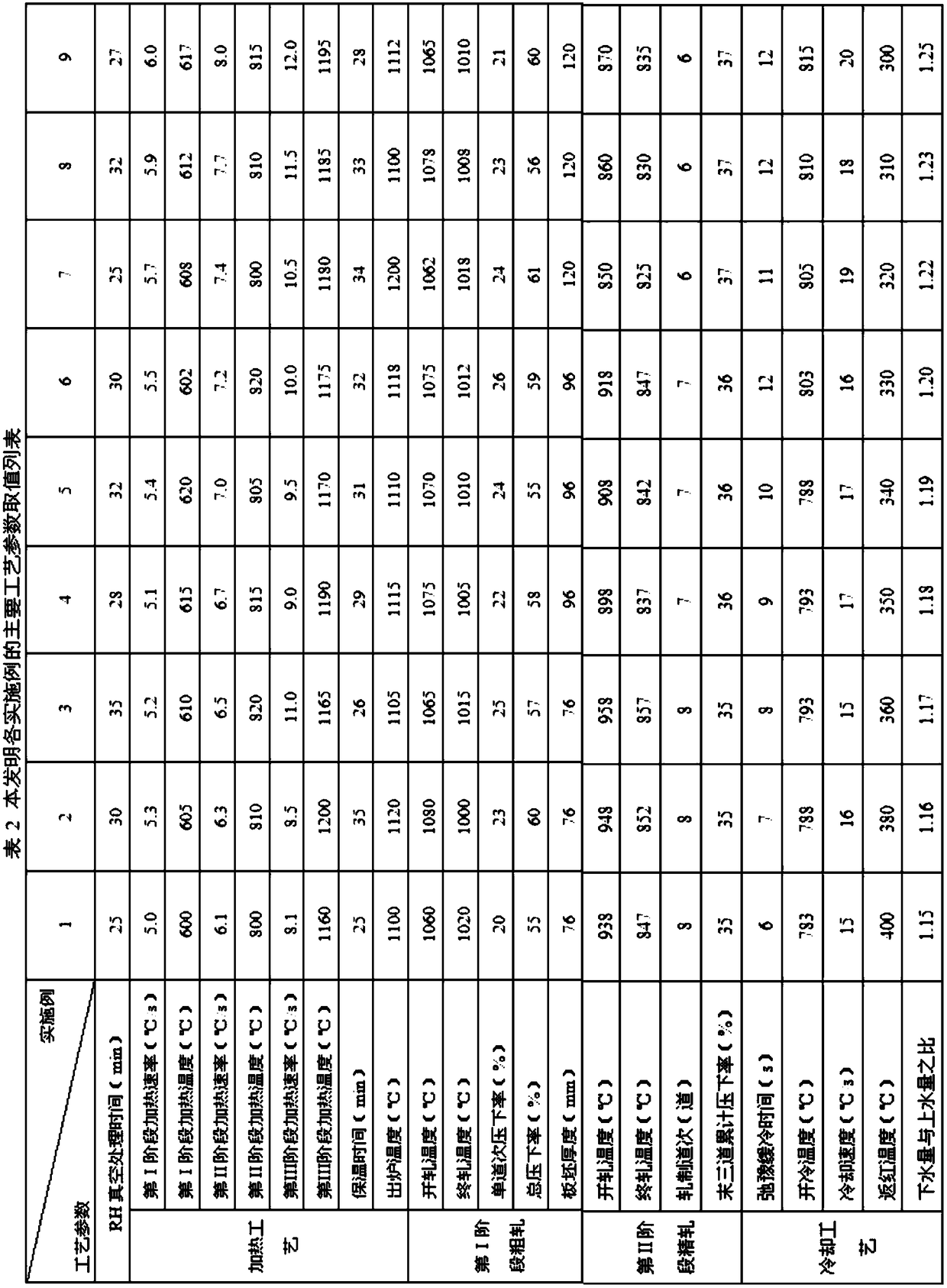

[0054] Table 2 is the value list of the main process parameters of each embodiment of the present invention;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

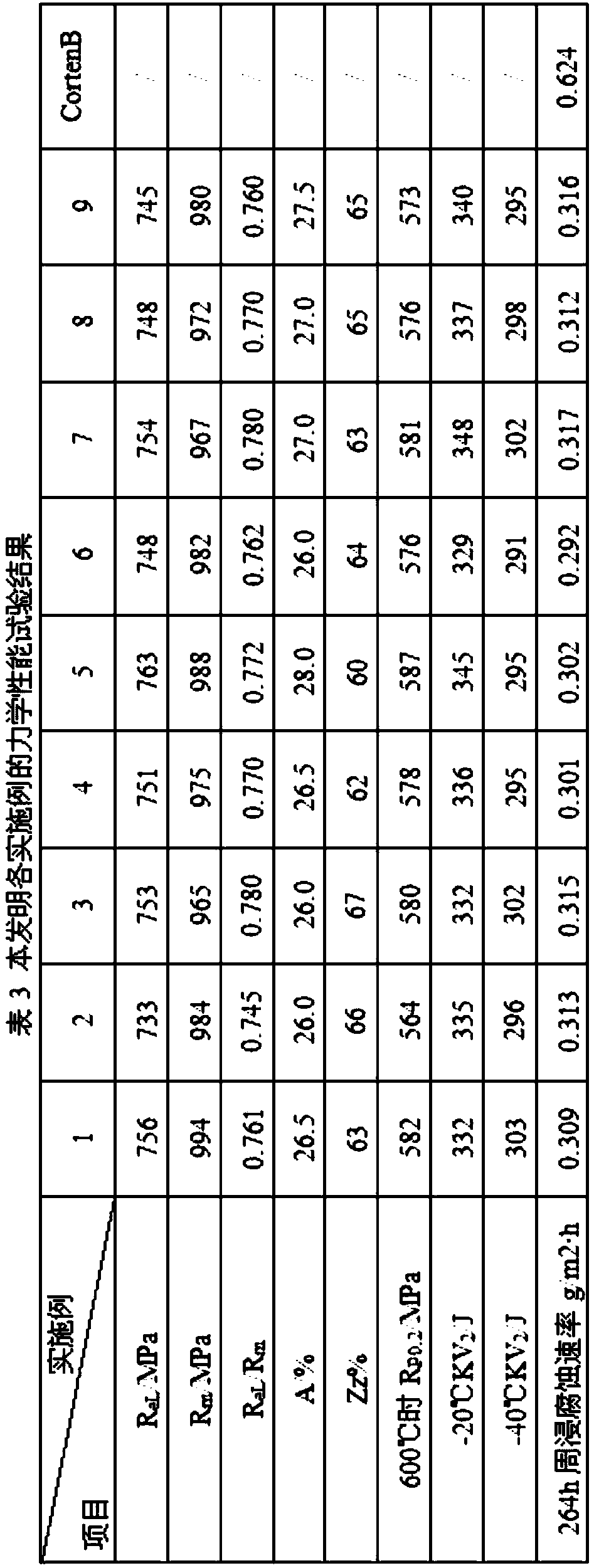

The invention belongs to the field of low alloy steel manufacturing, and particularly provides fire resistant and weather resistant steel with yield strength larger than or equal 690 MPa and used fora welding structure and a production method thereof. The steel comprises, by weight percent, 0.027 to 0.086% of C, 0.03 to 0.12% of Si, 1.65 to 2.12% of Mn, not larger than 0.003% of P, not larger than 0.002% of S, 0.21 to 0.40% of Mo, 0.12 to 0.25% of Cr, 0.12 to 0.28% of Cu, 0.21 to 0.43% of Ni, 0.052 to 0.095% of Nb, 0.078 to 0.122% of V, 0.007 to 0.018% of Ti, 0.0023 to 0.0072% of Zr, 0.010 to0.025% of Ta, 0.0012 to 0.0047% of N, 0.0034 to 0.0052% of O, and the balance Fe and inevitable impurities. Meanwhile, (2Zr+Ta) / O is equal to 5.28 to 6.31, 7C+3Mn is equal to 5.32 to 6.67%, Pcm is equal to C+Si / 30+(Mn+Cr+Cu) / 20+Ni / 60+Mo / 15+V / 10+5B smaller than or equal to 0.22%, and a product produced through the production method has the high strength toughness, excellent fire resistance and weather resistance(obviously superior to CortenB steel) and lamellar tearing resistance.

Description

technical field [0001] The invention belongs to the field of low-alloy steel manufacturing, and specifically provides a fire-resistant and weather-resistant steel for welded structures with a yield strength ≥ 690 MPa and a production method thereof. Background technique [0002] With the continuous development of iron and steel metallurgy technology, structural parts such as columns and beams of steel structures have put forward new requirements for steel plate strength, fire and disaster resistance, corrosion resistance, and earthquake resistance, while ordinary steel structures are poor in the construction industry. The ability to resist fire, disaster and corrosion is facing a severe test. In recent years, metallurgists at home and abroad have actively carried out research on fire-resistant, weather-resistant, and earthquake-resistant steels. Fire-resistant and weather-resistant steel can not only make up for the shortcomings of ordinary steel structures with poor fire re...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C38/02C22C38/58C22C38/42C22C38/44C22C38/46C22C38/48C22C38/50C21C7/10C21D8/02

CPCC22C38/02C21C7/0006C21C7/10C21D8/0226C21D2211/002C21D2211/005C22C38/42C22C38/44C22C38/46C22C38/48C22C38/50C22C38/58

Inventor 童明伟卜勇张开广范巍

Owner 武汉钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com