Top filling method for artificial pillar in goaf of mine

A technology of artificial pillars and gobs, applied in mining equipment, earthwork drilling, pillars/brackets, etc., can solve problems such as incomplete filling, poor pillar bearing capacity, and inability to play an effective supporting role, achieving Effects of improving safety and ensuring construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

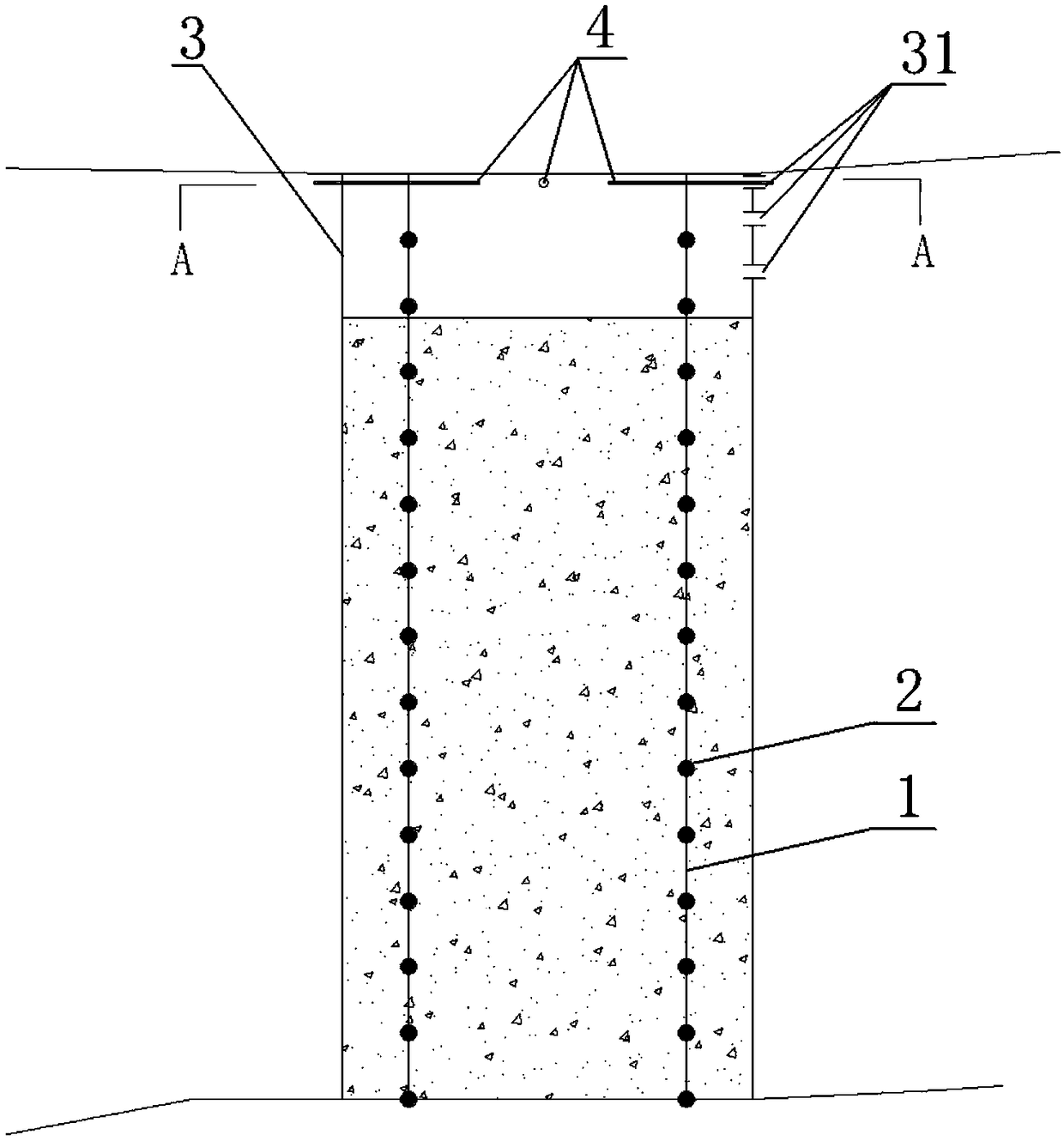

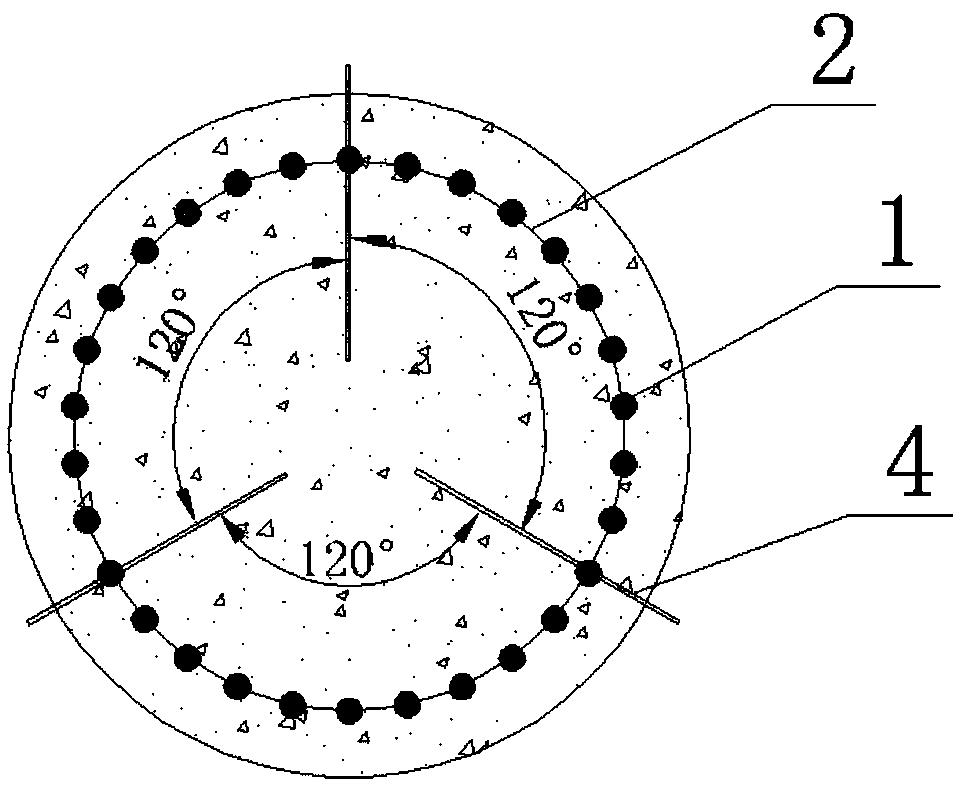

[0020] The method for connecting the roof of the artificial pillar in the goaf of the mine disclosed in this embodiment is aimed at the artificial pillar of the reinforced concrete structure. China Machinery pumps concrete to form the roofing section of the artificial pillar, and then uses the reserved grouting pipe to inject high-pressure grout at the junction of the pillar and the roof, so that the artificial pillar and the roof are fully connected to the roof, specifically including the following steps:

[0021] (1) Before pouring the top section of the artificial pillar near the roof, measure the distance between the top of the poured column and the roof.

[0022] (2) Prefabricate the template of the top section according to the measured data.

[0023] from figure 1 It can be seen that the formwork is mainly a side plate 3 on the periphery of the top of the column. The upper end of the side plate is in close contact with the top plate. Concrete delivery holes 31 are respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com