U-shaped tube heat exchange closed cycle downhole thermoelectric power generation system and method

A technology of thermoelectric power generation and U-shaped tubes, which is applied in geothermal energy systems, geothermal energy, household heating, etc., can solve the problems that restrict the development of geothermal power generation, wellbore scaling, and subsidence of the ground, so as to achieve heat generation without water intake , reduce emissions, and stabilize power supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

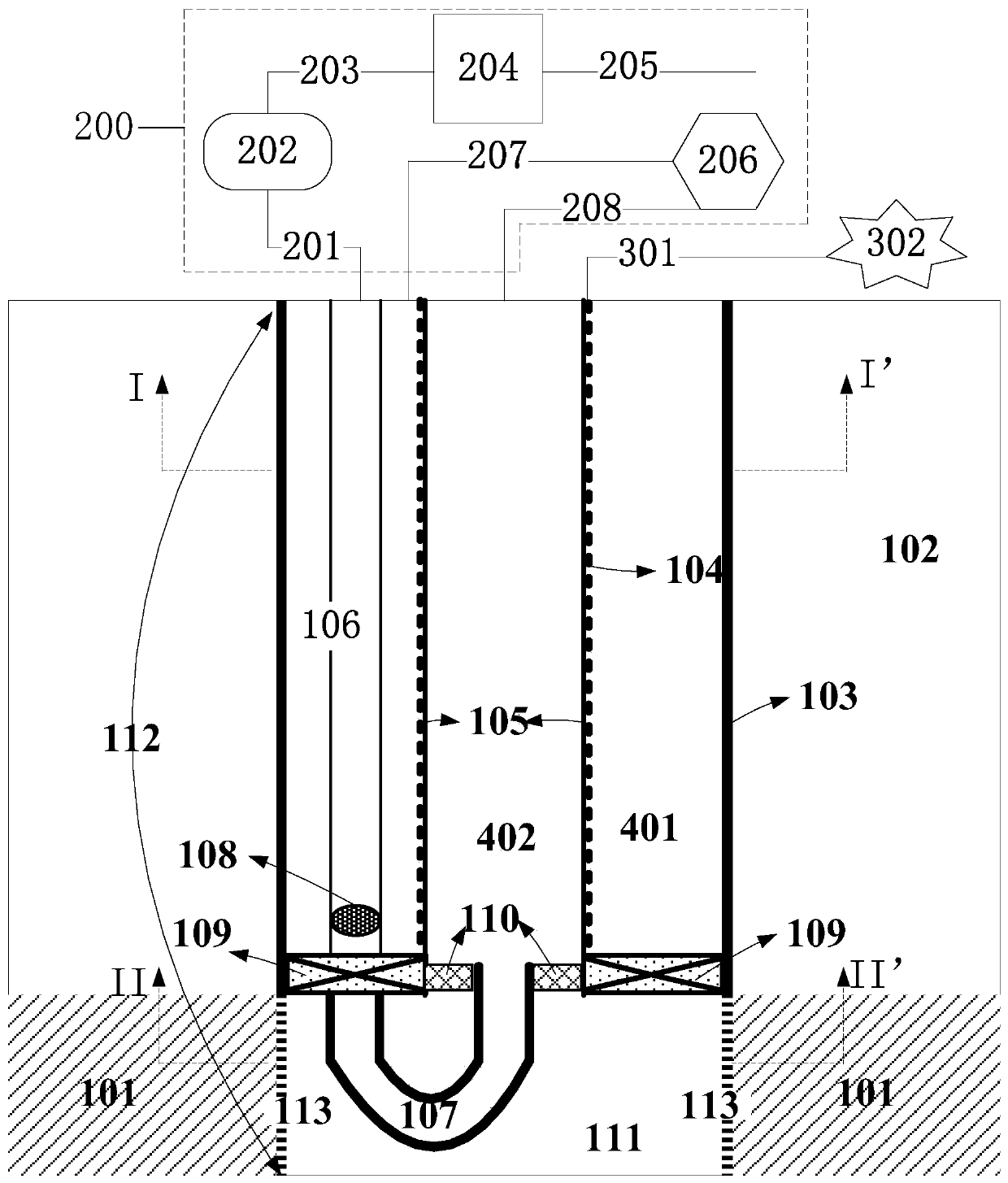

[0046] like figure 1 A U-shaped tube heat exchange closed cycle downhole thermoelectric power generation system shown includes: a wellbore 112 , a fluid circulation module 200 and an electric energy external transmission module 302 .

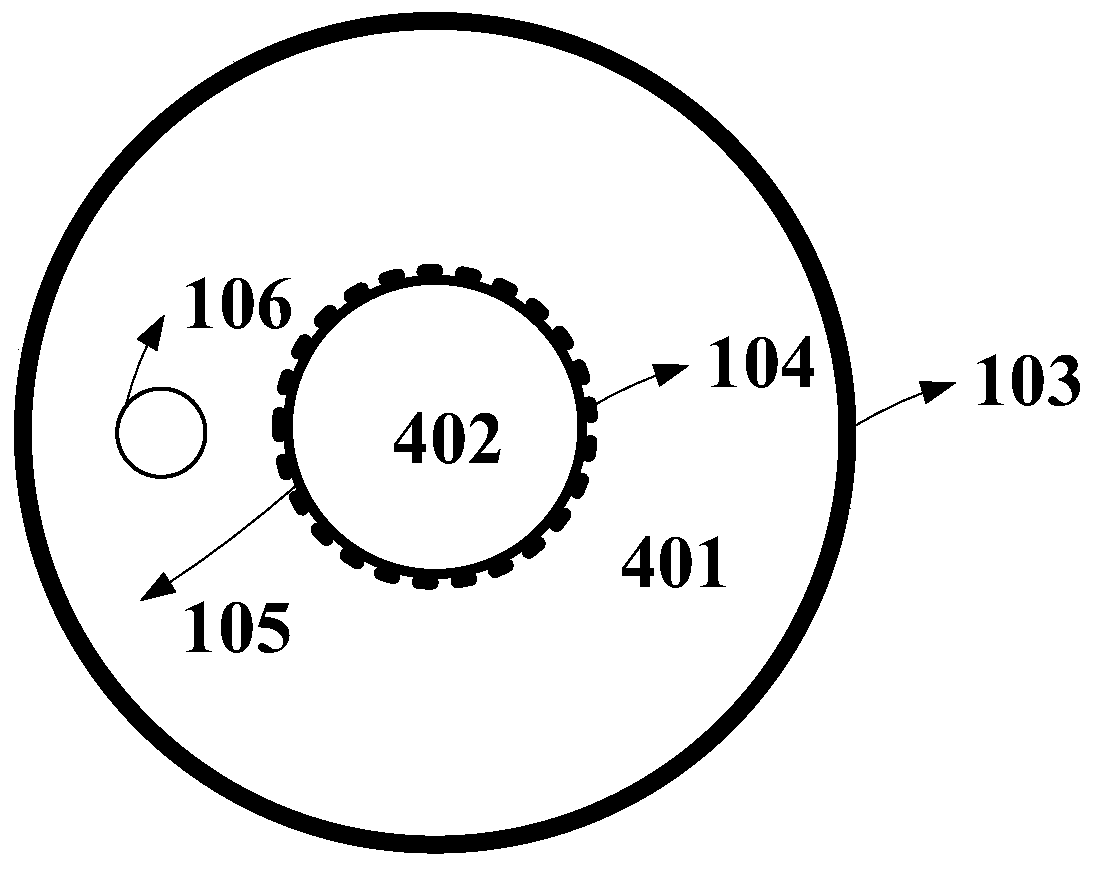

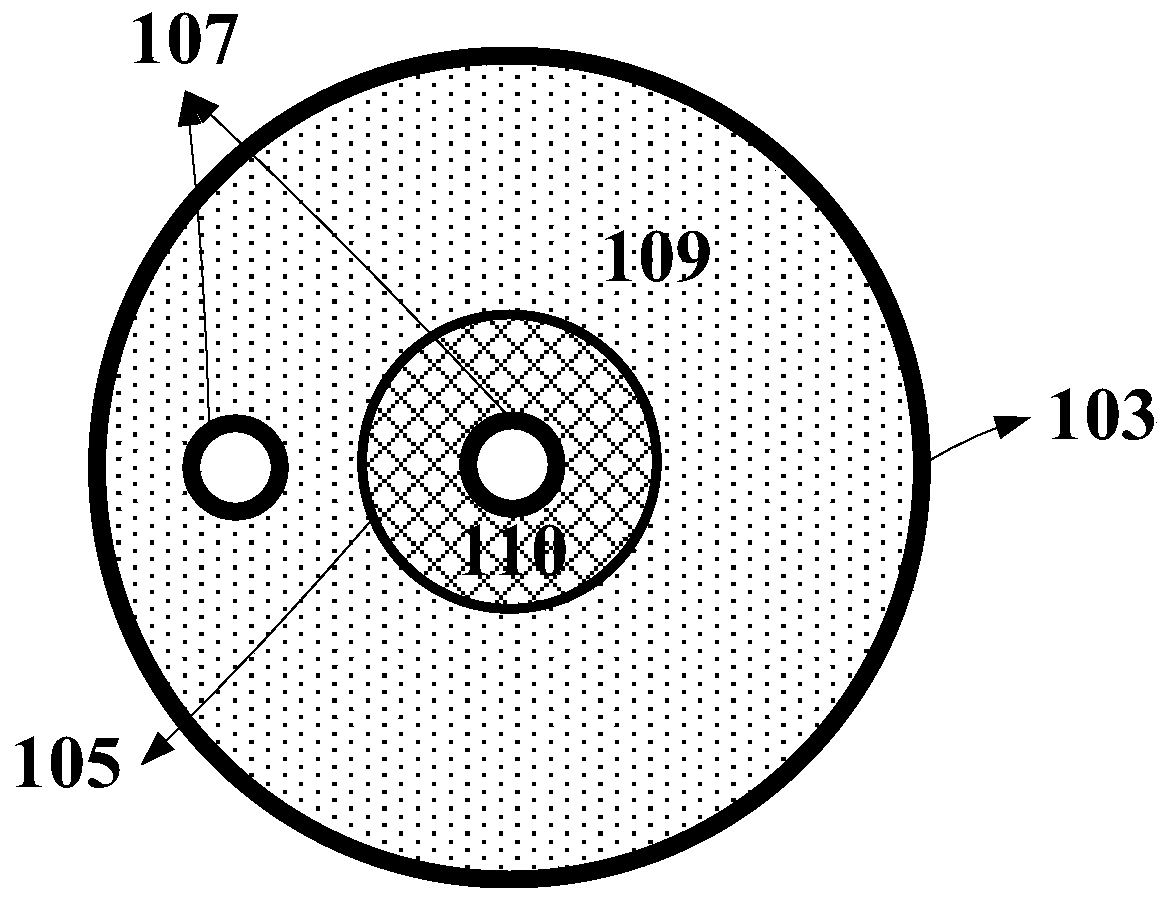

[0047] Further, the wellbore 112 includes a casing 103 that drills through the overlying formation 102 and the production layer 101 from top to bottom, an oil pipe 105 embedded in the casing 103, and a thermoelectric generator set on the outer wall of the oil pipe 105. Module 104, cold fluid injection pipe 106 and U-tube heat exchanger 107 embedded in casing 103 located within the production zone. The part of the casing 103 located in the production layer 101 is provided with a perforation section 113 . The top of the oil pipe 105 is flush with the top of the casing 103 , and the bottom is located at the junction of the overlying formation 102 and the production layer 101 over the production layer.

[0048] Specifically, the production layer 1...

Embodiment 2

[0069] like Figure 4 The U-tube heat exchange closed cycle downhole thermoelectric power generation system under the condition of tubing injection shown, and figure 1 The difference of the U-shaped tube heat exchange closed circulation downhole thermoelectric power generation system in the case of oil casing annular injection in the first embodiment shown is that the cold fluid injection pipe 106 is lowered from the oil pipe 105, that is, the cold fluid injection pipe 106 is disposed in the tubing flow passage 402 . A portion of the cold fluid diverted from the downhole flow splitter 108 enters the tubing flow channel 402 and flows up the tubing flow channel 402 out of the surface. The U-shaped tube heat exchanger 107 communicates with the cold fluid injection tube 106 through a through-type oil tube plug 110 . The U-shaped tube heat exchanger 107 passes through the packer 109 and communicates with the oil jacket annular flow channel 401 . Specifically, the lower end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com