Novel floating bush for outer engaging gear pump

A floating bushing and gear pump technology, applied in the field of hydraulic components, can solve problems such as reduced bearing life, reduced bearing capacity, flow pulsation, etc., and achieve the effects of reducing axial leakage, reducing vibration and noise, and improving overturning moment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, the present invention is described in further detail:

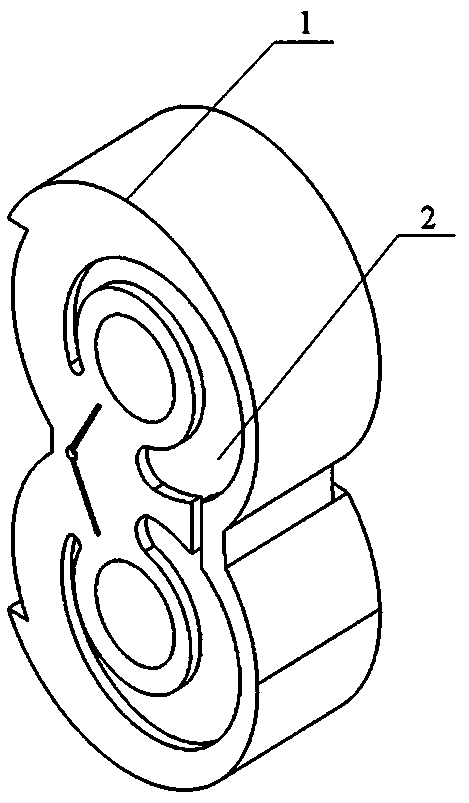

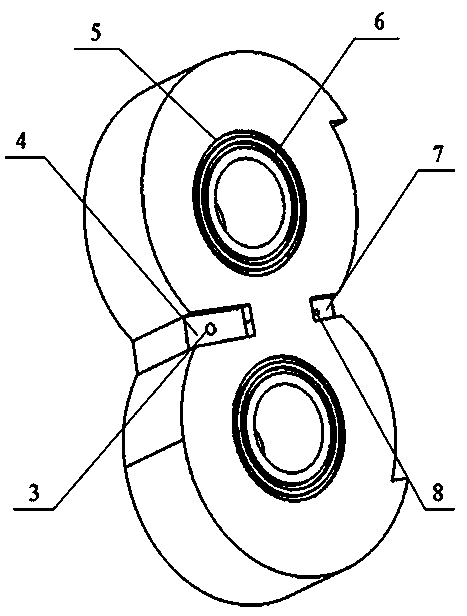

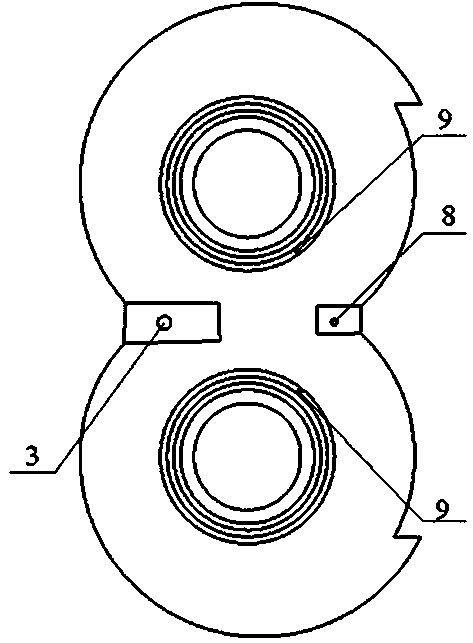

[0022] A new type of floating bushing for external gear pumps, mainly composed of a bow-shaped balance area (2) on the "8"-shaped floating bushing, a high-pressure oil hole (3), a high-pressure unloading groove (4), a low-pressure unloading Groove (7), circumferential hydraulic oil collection tank (5), oil return hole (8), oil drain hole (9), oil drain return tank (10), pre-boost oil chamber (11), etc.;

[0023] Such as figure 1 , 5 As shown, the new type of floating bush adopts an "8"-shaped structure, and its outer edge adopts a transition curve section with a gradually increasing radius of curvature, that is, a gradual transition from the high-pressure oil discharge chamber to the low-pressure oil suction chamber, so that the tooth tip clearance gradually increases. It is enough to stop at the position 2 gear teeth away from the low-pressure oil suction chamber. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com