A nuclear power plant pressure pipeline acoustic emission detector and method

A pressure pipeline and acoustic emission technology, applied in the pipeline system, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of large measurement error and large deviation, reduce the response difference, increase the distance, and avoid the application of preset The effect of tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

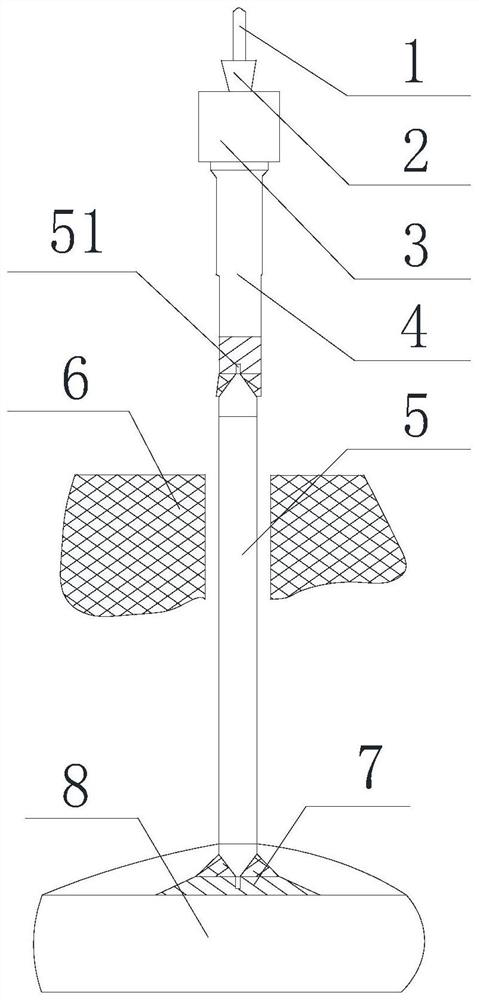

[0042] Such as figure 1 As shown, a nuclear power plant pressure pipeline acoustic emission detector includes a launch sensor 3, a signal cable 1 is arranged on the top of the launch sensor 3, and a first waveguide rod 4 is arranged on the bottom of the launch sensor 3 , the first waveguide rod 4 and the launch sensor 3 are integrated structures, and also include a second waveguide rod 5, one end of the second waveguide rod 5 is connected to the end of the first waveguide rod 4, and the other end is connected to the adapter seat 7 connection, the adapter seat 7 is installed on the main pipeline 8 or the wave pipe, the length of the second waveguide rod 5 is greater than the thickness of the insulation layer 6, and the connection method is welding, bonding or screw connection Compared with bonding and threaded connections, welding is more conducive to the propagation of acoustic emission signals. In order to improve the propagation characteristics of acoustic emission signals, ...

Embodiment 2

[0044] Such as figure 1 As shown, this embodiment is based on Embodiment 1. The two ends of the second waveguide rod 5 are tapered structures, and the ends of the tapered structure are small-sized ends, which are connected with the first waveguide rod 4 on the outside of the tapered structure. A welding zone is formed between the outside of the tapered structure and the adapter seat 7; the end of the tapered structure is provided with a positioning pin 51, and the end of the first waveguide rod 4 and the top of the adapter seat 7 are both provided There is a positioning hole matched with the positioning pin 51; the positioning pin 51 is a cylinder, and the positioning hole is a circular hole; the connection between the transmitting sensor 3 and the signal cable 1 is provided with a sealing structure 2, and the sealing The structure 2 is in contact with the top of the transmitting sensor 3, and the sealing structure 2 is provided with a through hole for passing the signal cable...

Embodiment 3

[0048] Such as figure 1As shown, this embodiment is based on Embodiment 1 or Embodiment 2. The adapter seat 7 is a trapezoidal structure with a large lower end and a small upper end; The material is consistent with or close to the main pipe 8 or the wave pipe.

[0049] Based on the detection method of the detector described in any one of embodiment 1 to embodiment 3, the described comprises the following steps:

[0050] 1), install the adapter seat 7 on the main pipe 8 or the wave pipe;

[0051] 2), connecting one end of the second waveguide rod 5 to the adapter seat 7;

[0052] 3), and then lay the insulation layer 6 on the main pipeline 8 or the wave pipe, so that the second waveguide rod 5 protrudes from the insulation layer 6;

[0053] 4) Connect the other end of the second waveguide 5 to the end of the first waveguide 4 . .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com