High-pressure gas conveying pipe leakage monitoring system and method

A technology for conveying pipelines and high-pressure gas, which is applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., and can solve problems such as leak alarm positioning of high-pressure gas pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

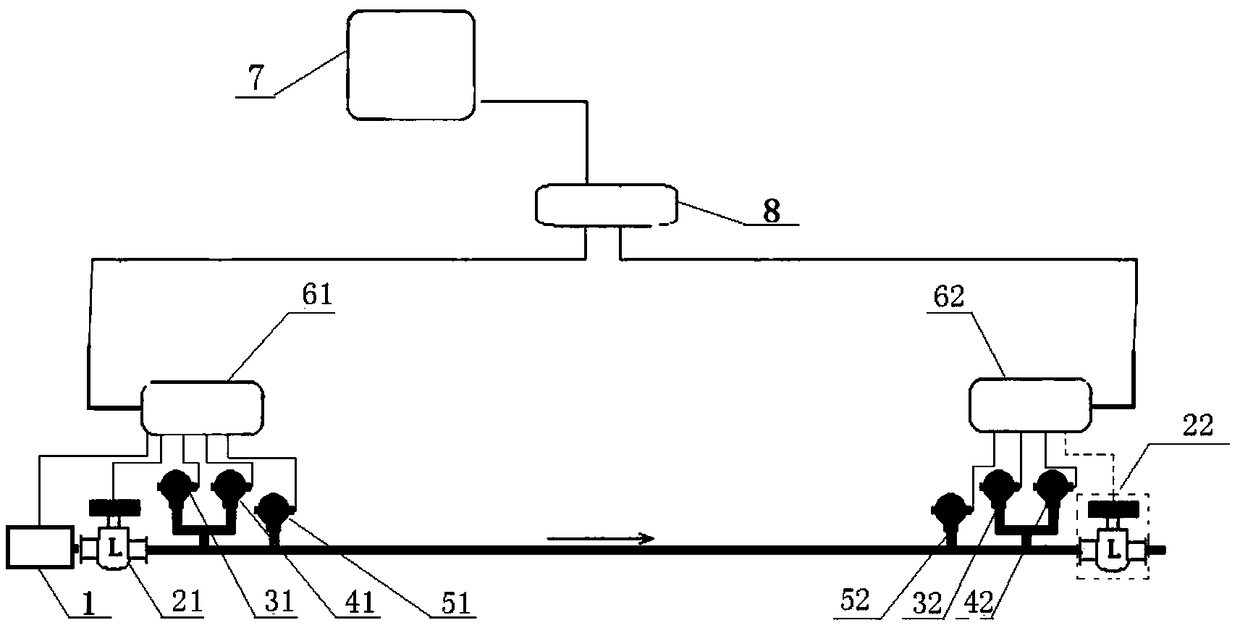

[0027] In this example combined figure 1 The leak monitoring system of high-pressure gas transmission pipeline is described. Such as figure 1 As shown, it includes: a first data acquisition and processing device 61 arranged in the first section of the high-pressure gas delivery pipeline, a first flow sensor 21, a first vibration signal sensor 31, a first pressure sensor 41, a first temperature sensor 51, and The second data acquisition and processing device 62, the second vibration signal sensor 32, the second pressure sensor 42, and the second temperature sensor 52 are arranged in the second section of the high-pressure gas delivery pipeline; the first section is located upstream of the second section.

[0028] The first flow sensor 21 is connected to the first data acquisition and processing device 61 through a shielded signal cable. The first flow sensor 21 is a high-precision flow signal sensor, and the collected flow signal can be sent to the first data collection and p...

Embodiment 2

[0051] An embodiment of the present invention provides a leakage monitoring method of a high-pressure gas transmission pipeline, which is applied to the high-pressure gas transmission pipeline leakage monitoring system described in the first aspect; the high-pressure gas transmission pipeline leakage monitoring method includes: collecting the flow rate of the first section of the high-pressure gas transmission pipeline Signal, vibration signal, pressure signal, temperature signal; collect the vibration signal, pressure signal, temperature signal of the second section of the high-pressure gas pipeline; the first section is located upstream of the second section; the flow signal of the first section , vibration signal, pressure signal, and temperature signal are sent to the first data acquisition and processing device 61, and the flow signal, vibration signal, pressure signal, and temperature signal of the first section are processed by the first data acquisition and processing de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com