Combustion control method for hot rolling pulse heating furnace

A control method and pulse heating technology, applied in furnace control devices, furnace monitoring devices, lighting and heating equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0169] Embodiments of the present invention are described in detail below, and the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are provided, but the protection scope of the present invention is not limited to the following embodiments.

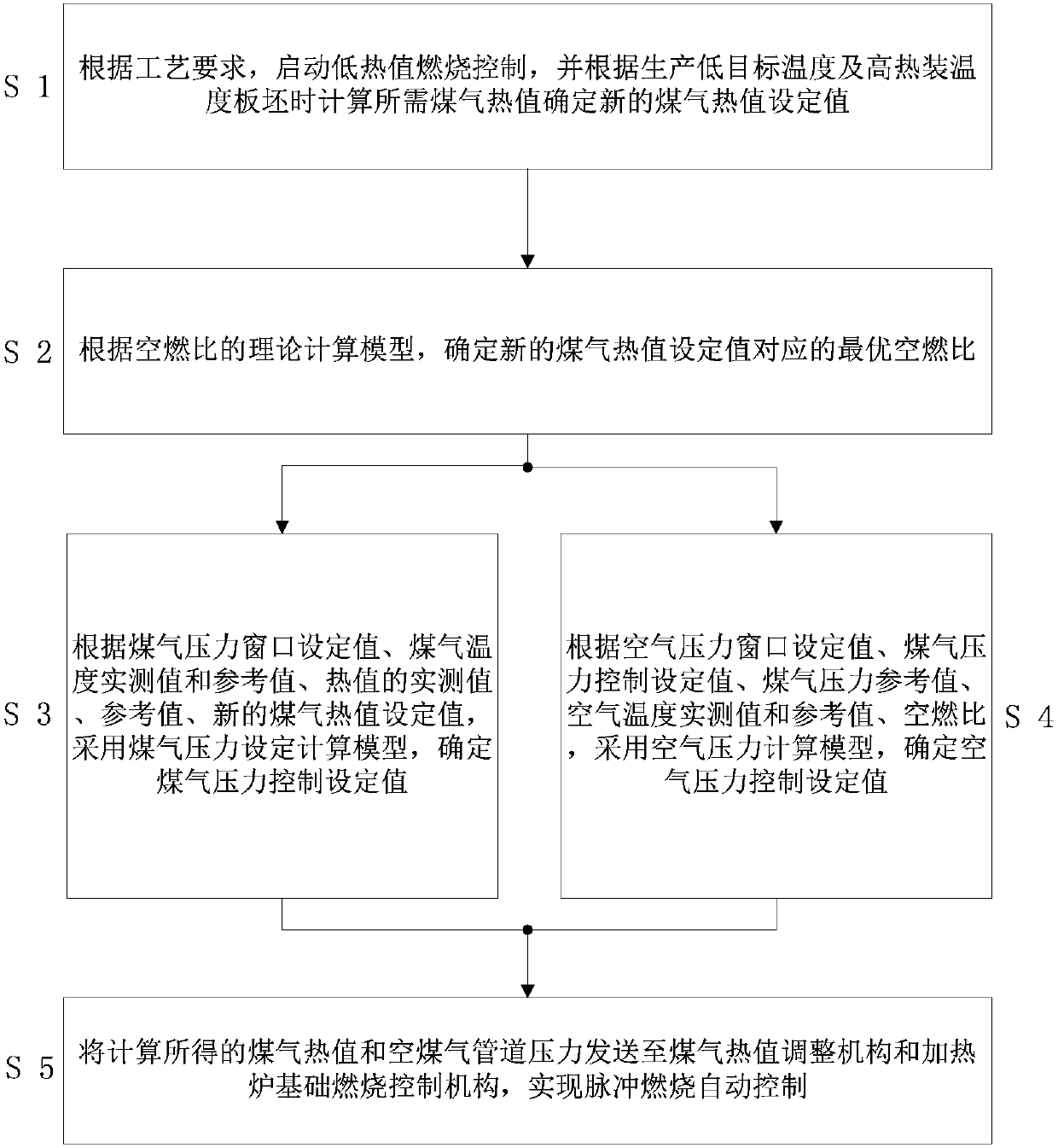

[0170] Taking a certain hot-rolling production line as an example, the control method of the present invention determines that when the production line pulse heating furnace produces slabs with a low target temperature for hot charging, a new fuel calorific value is set, and by using the gas pressure formula and air pressure The formulas determine the mixed gas pressure setpoint and the combustion air pressure setpoint.

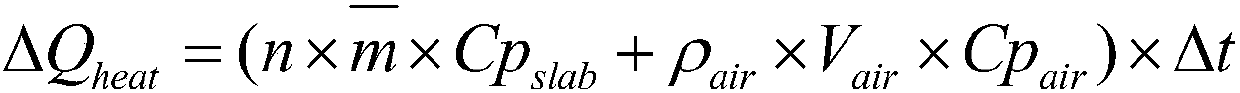

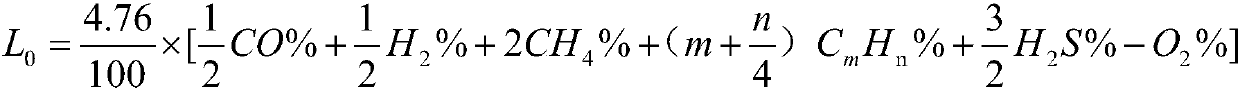

[0171] When the pulse heating furnace is producing a slab with a low target temperature for hot charging, the steps to determine the new gas calorific value and the control method of the gas and air pressure form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com