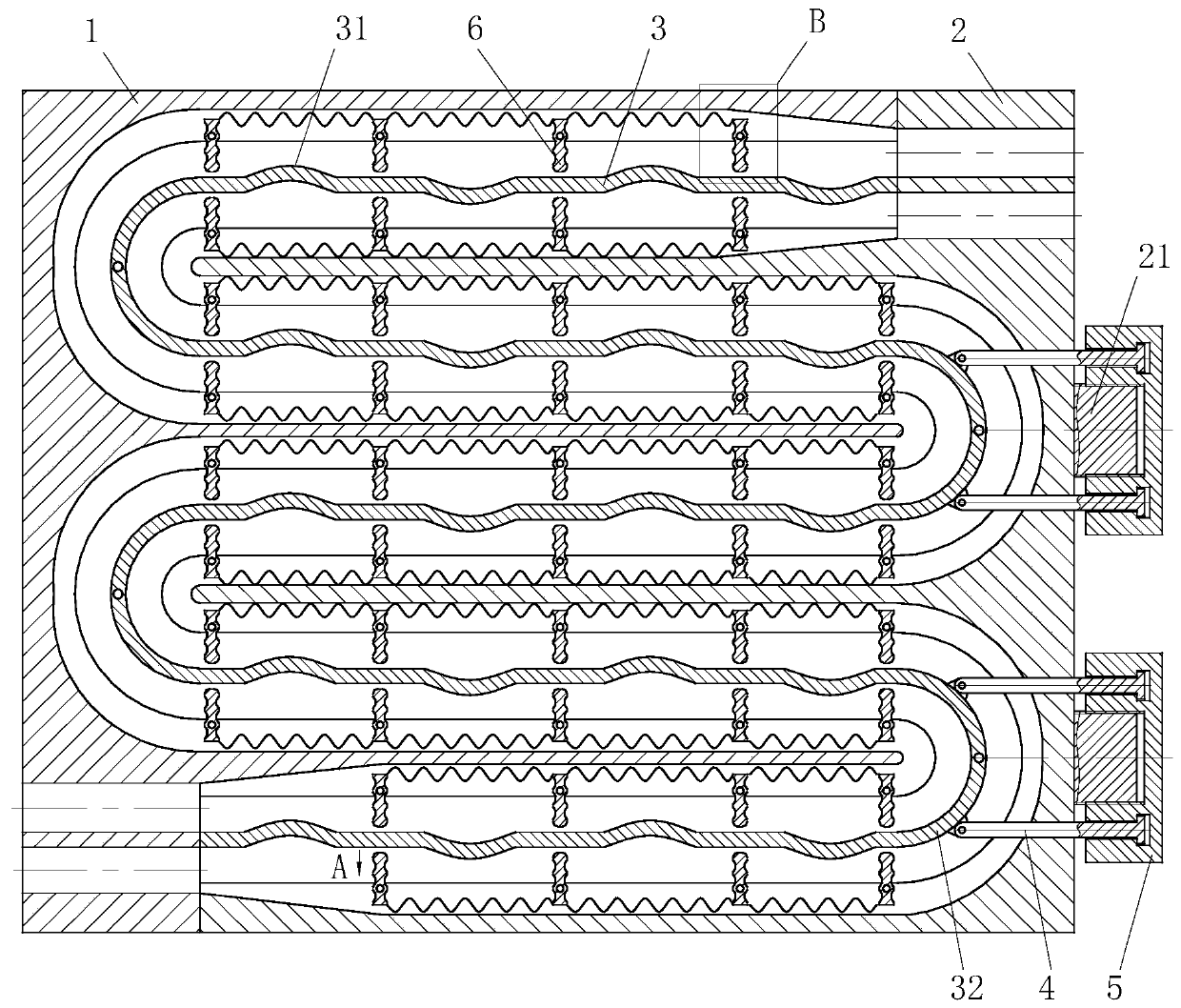

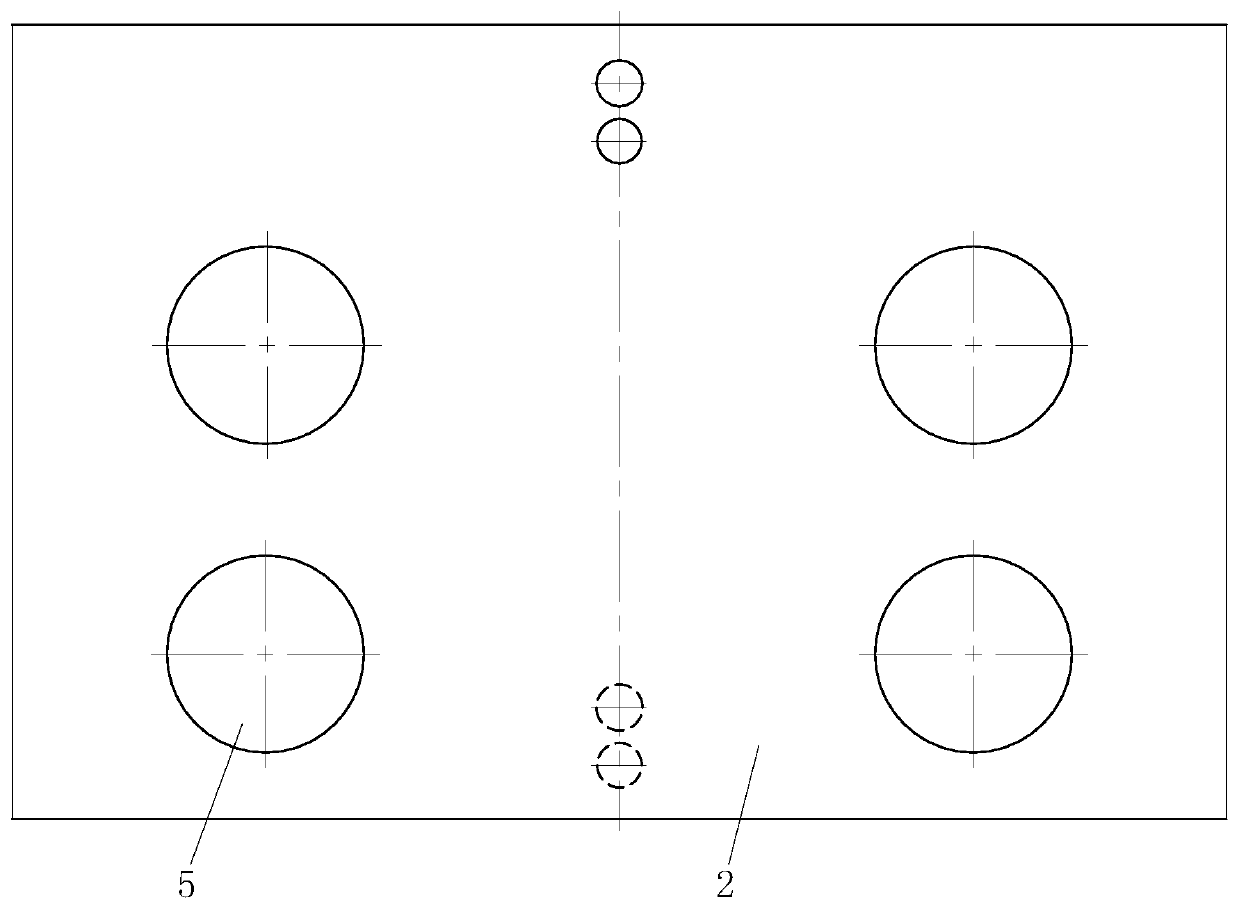

A heat exchanger for chemical production

A technology for heat exchangers and chemical production, which is applied in the field of heat exchangers for chemical production, which can solve problems such as inconvenient installation and achieve the effect of reducing volume and improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

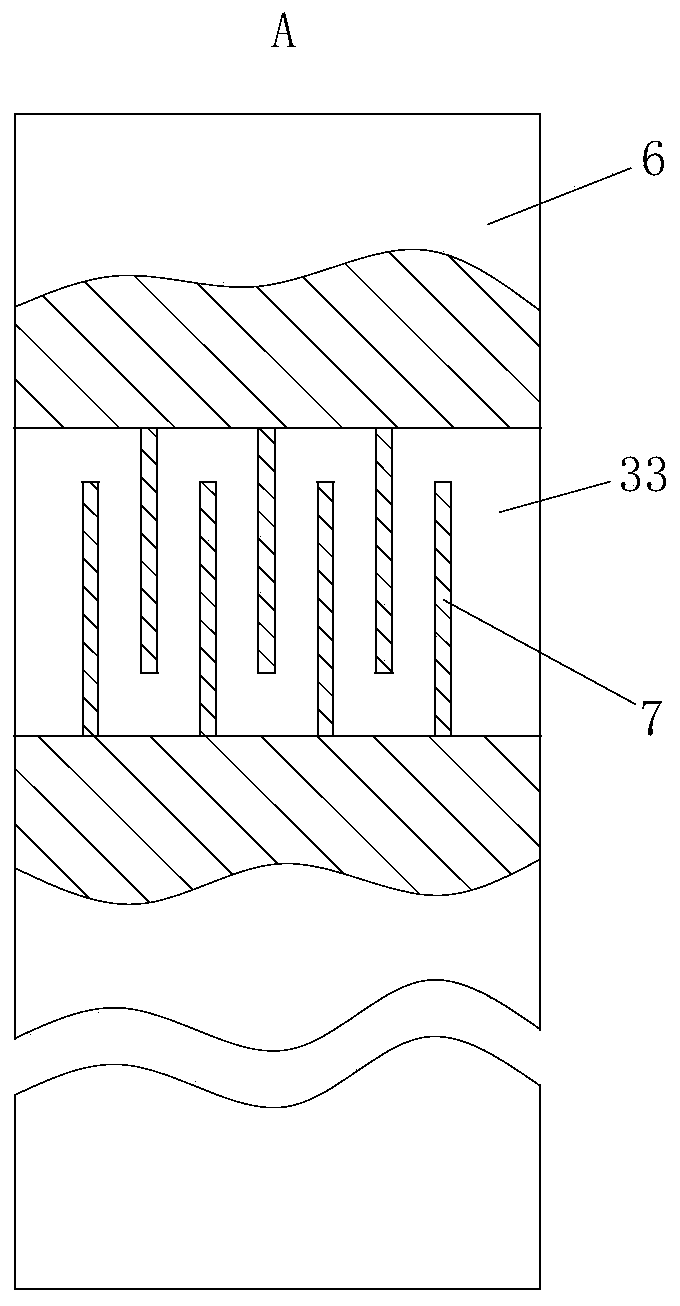

[0035] As the first embodiment of the drainage groove 33 in the present invention, the two sides of the drainage groove 33 of the swing plate 6 are alternately provided with baffles 7; one end of the baffle 7 is fixedly connected to the side wall of the drainage groove 33; When working, the flowing liquid pushes the oscillating plate 6 to swing after overcoming the elastic force of the torsion spring, and the flowing liquid bypasses the baffle plate 7 in the drainage groove 33 on the oscillating plate 6 and then discharges, and the liquid bends in the drainage groove 33 on the oscillating plate 6 Heat exchange is performed through the heat exchange partition plate 3 during the flowing process, and the liquid constantly changing the direction of movement further improves the heat exchange efficiency.

[0036] As the second embodiment of the drainage groove 33 in the present invention, sliding grooves 331 are arranged on both sides of the drainage groove 33 of the swing plate 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com