Defect location method for sheet metal based on active sweep frequency acoustic excitation

A technology of metal thin plate and positioning method, which is applied in the detection of response signals, the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, and the use of sound waves/ultrasonic waves/infrasonic waves for material analysis, etc. It can solve problems such as positioning errors and positioning errors, and achieve accuracy sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

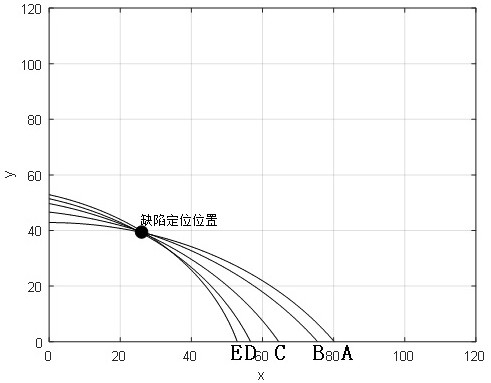

[0028] A thin metal sheet defect location method based on active sweeping acoustic excitation, the innovation of which is that the method includes:

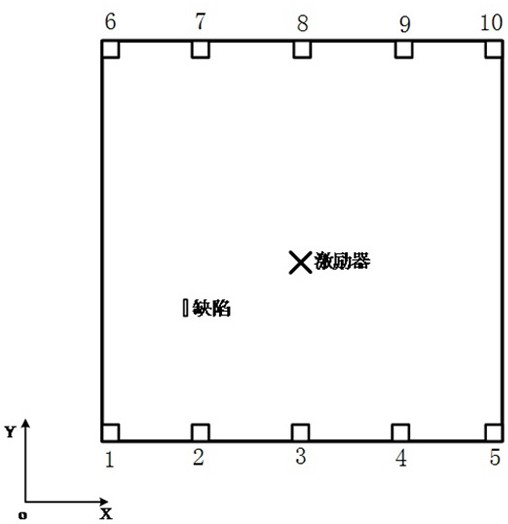

[0029] 1) Device layout: multiple piezoelectric ceramic sensors are arranged on the surface of the metal sheet to be tested, and the multiple piezoelectric ceramic sensors are distributed in a ring, and the area surrounded by multiple piezoelectric ceramic sensors forms a detection area; A dynamic actuator, the actuating actuator is located in the middle of the detection area; the surface of the metal sheet to be tested is used as the coordinate plane to establish a two-dimensional rectangular coordinate system to obtain the coordinates of each piezoelectric ceramic sensor in the two-dimensional rectangular coordinate system;

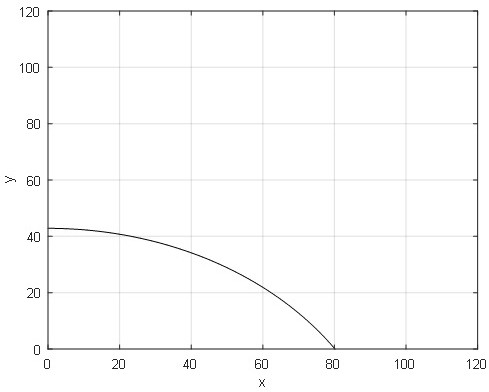

[0030] 2) Signal acquisition: control the actuation exciter to apply a frequency sweep excitation signal to the metal sheet to be tested, and at the same time, obtain detection signals through multiple piez...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com