A kind of coaxial zigzag band-like injection slow-wave structure

A technology similar to coaxial and wave structure, applied in the field of ribbon beam traveling wave tube slow wave system, can solve the problems of narrow bandwidth and poor transmission characteristics, and achieve the effect of increasing bandwidth and reducing dispersion characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

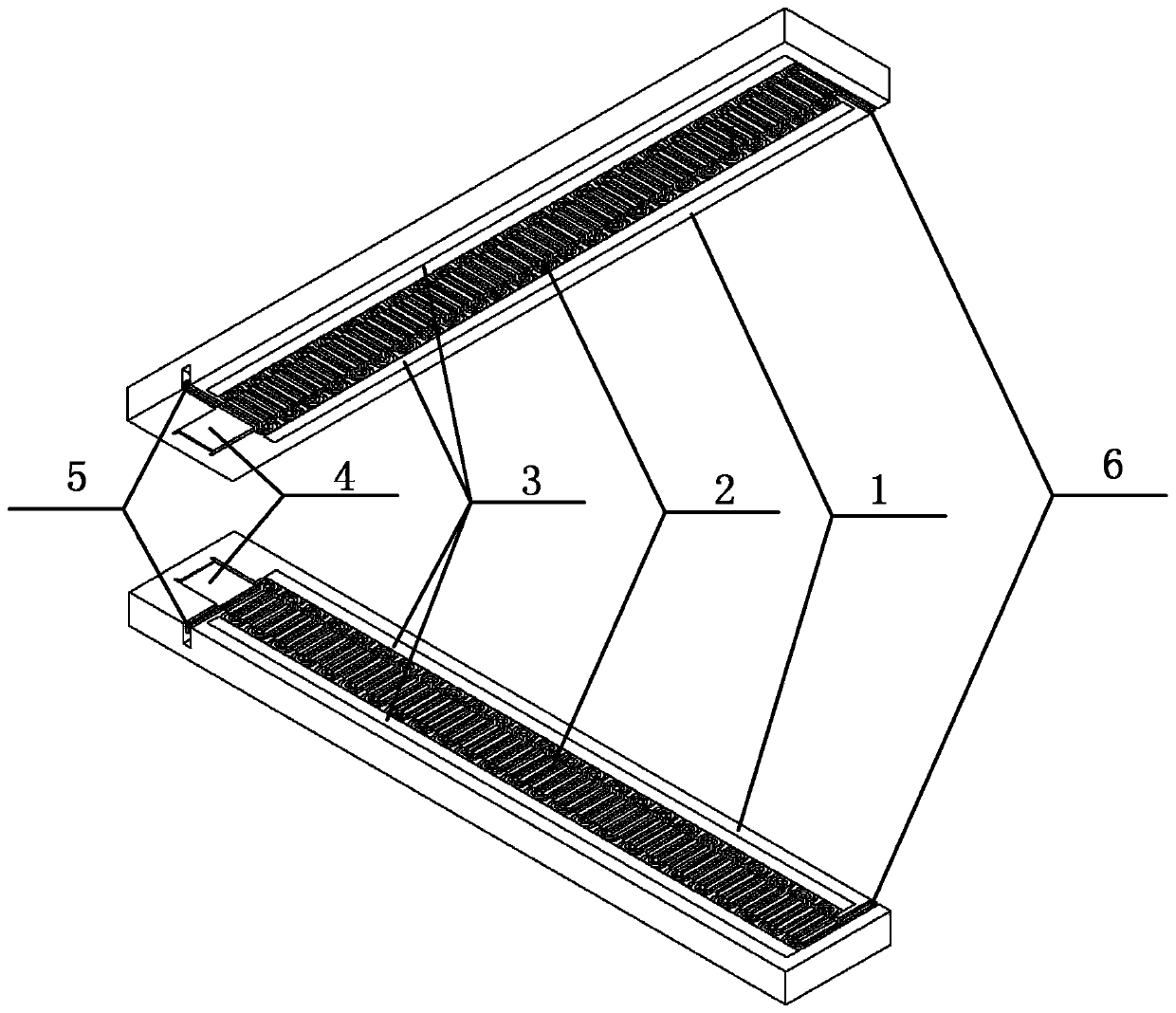

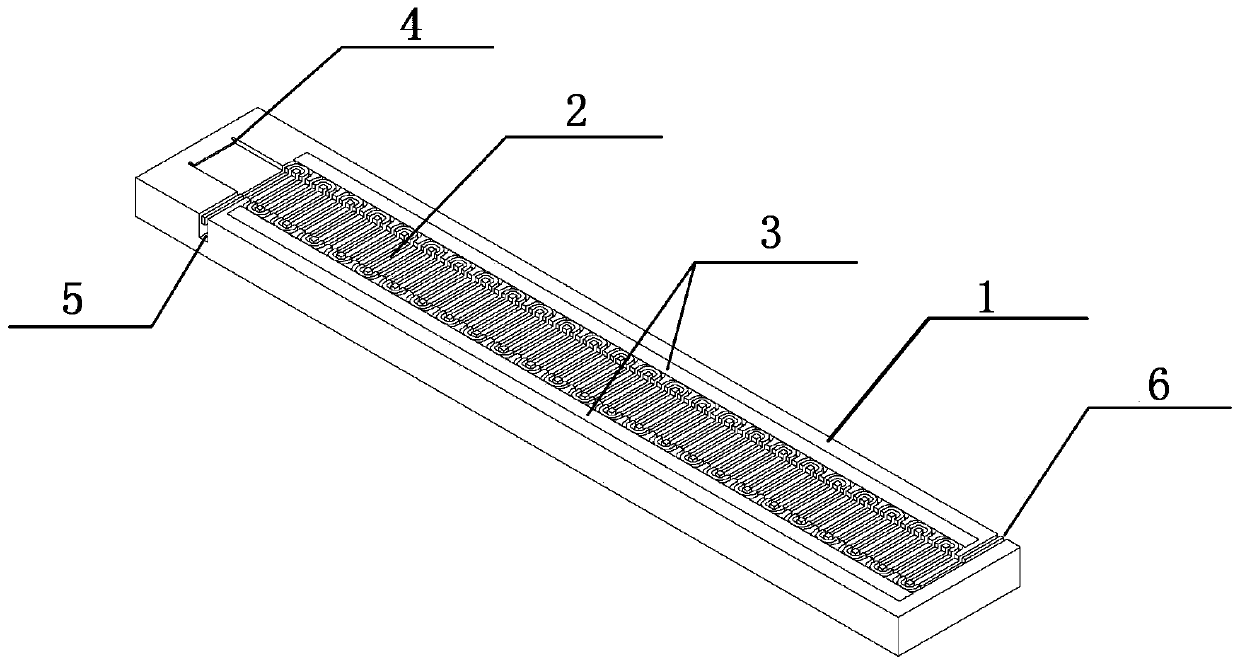

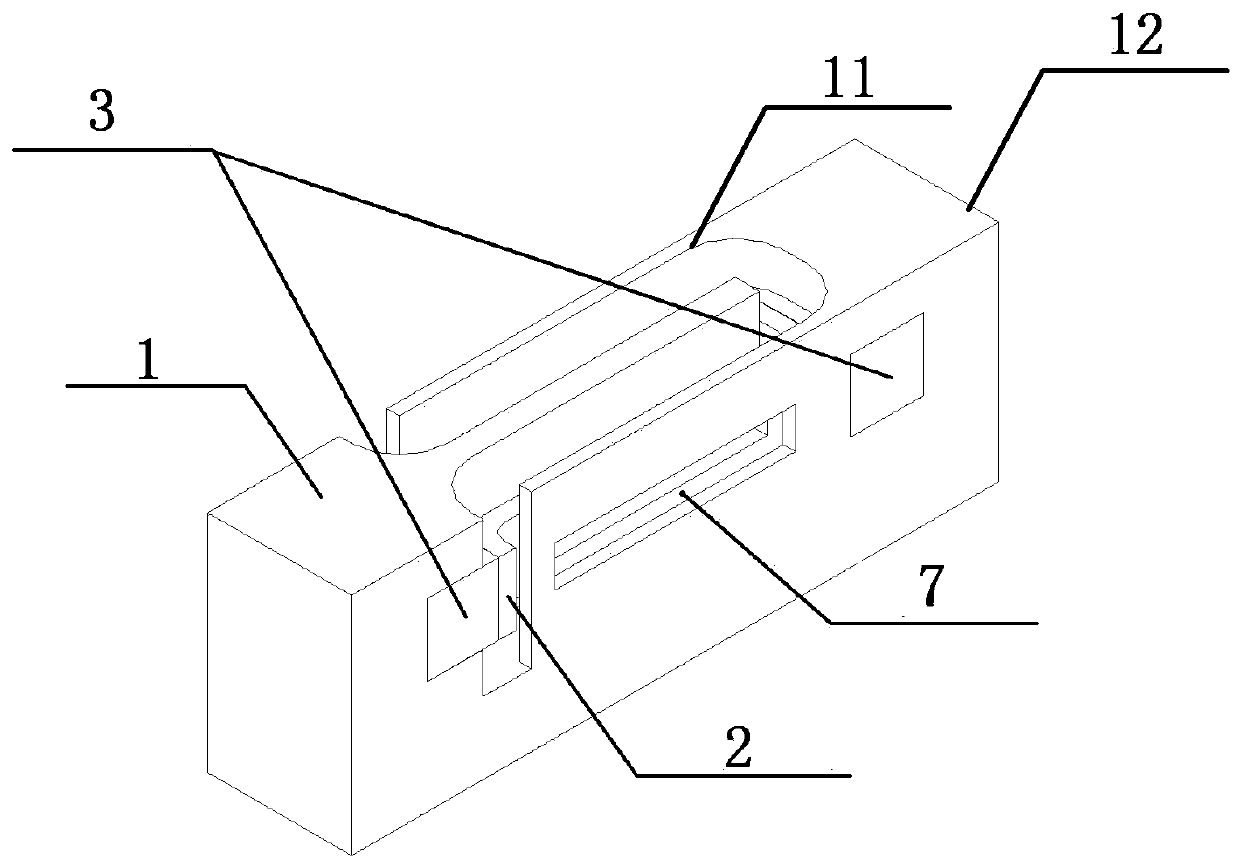

[0021] figure 1 It is a structural diagram of a specific embodiment of the quasi-coaxial meandering ribbon injection slow wave structure of the present invention. In order to show the inner structure of the ultra-broadband planar double-injection slow-wave structure more clearly, figure 1 In the center, the quasi-coaxial meandering strip-shaped beam slow-wave structure is divided into upper and lower halves by taking the plane where the electron beam is located as the cross-section. figure 2 yes figure 1 A magnified view of the lower half of the quasi-coaxial meander-ribbon-note slow-wave structure shown. Such as figure 1 and figure 2 As shown, the coaxial meandering strip-shaped slow-wave injection structure of the present invention includes a metal shell 1 , a metal slow-wave line 2 and two dielectric support rods 3 . Same as the conventional slow wave structure, the electron entrance 4, signal input port 5 and signal output port 6 of the electron gun will be added at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com