Switch reluctance motor

A technology of switched reluctance motors and rotors, which is applied in the direction of electrical components, electromechanical devices, magnetic circuit static parts, etc. It can solve the problem of small starting torque, reduce torque ripple, reduce rotor saturation, and output average rotation speed The effect of moment enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A switched reluctance motor, through changing the curvature of the top of the rotor pole teeth, a variable air gap is formed between the rotor and the stator, thereby changing the inductance performance of the motor, increasing the starting torque, increasing the output torque, and reducing torque ripple.

Embodiment 2

[0021] As a specific structure of Embodiment 1, the stator teeth poles are pole shoe pole teeth, and the rotor tooth poles are flat arc pole teeth with variable air gap.

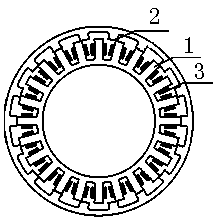

[0022] Such as figure 1 , 2 , as shown in 3, where figure 1 It is a hub-type external rotor motor, the inner ring is the stator 1, and there are 24 tooth poles on the stator 1, and the outer ring is the rotor 2, and there are 18 tooth poles on the rotor 2. Each stator 1 pole tooth has a winding 3, a total of twenty-four, and every three individual windings 3 are connected in series to form a phase. The windings are divided into ABCD four-phases, and each phase has six windings.

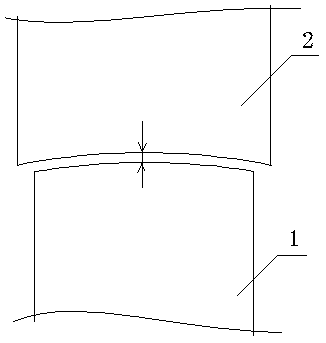

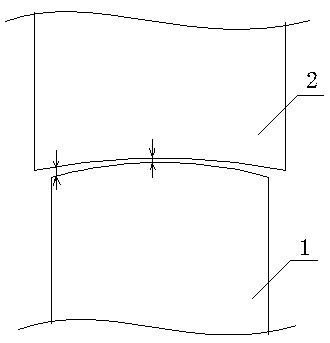

[0023] figure 2 The middle is the existing equidistant structure, the air gap is generally fixed at 3mm, and image 3 The flat arc structure is adopted in the center, and the air gap is a comparable gap, with the longest and shortest points.

Embodiment 3

[0025] As a specific structure of Embodiment 2, the single-side air gap between the rotor and the stator is between 1.7 mm and 3 mm, and as the rotor rotates, the length of the air gap between the rotor pole teeth and the stator pole teeth changes continuously.

[0026] The shortest part of the air gap is 0.18mm, and the longest is 0.37mm. When the rotor rotates clockwise, the air gap is larger when the air gap is 0.37mm, and the minimum value of the inductance is smaller than before. The minimum point of the air gap is 0.18mm at this time. Since the total air gap area is the same, the maximum inductance value is almost the same as that of the prior art. Figure 4 The inductance characteristic diagram in the figure is the same as the analysis. Among the figures, a is the inductance curve of the prior art, and b is the inductance curve of the present invention. It can be seen that the inductance curve of the present invention has a longer minimum inductance zone and the same max...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com