A kind of beef rib and its production process

A production process, the technology of beef ribs, applied in metal processing, food science, etc., can solve the problems of inconvenient tearing, and achieve the effect of convenient tearing operation, convenient layering, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The production technology of beef ribs comprises the steps:

[0028] Step 1: Prepare 45g of beef gluten and soak it in clear water, then prepare 3g of edible salt, 3.5g of white sugar, 8g of vegetable oil, 3g of sesame, 3g of pepper, 5g of cumin, 2g of spices and 3g of food essence, and mix them Put it in a basin for later use;

[0029] Step 2: Put the beef gluten soaked in step 1 into a pot filled with water and cook for 1.5 hours until cooked;

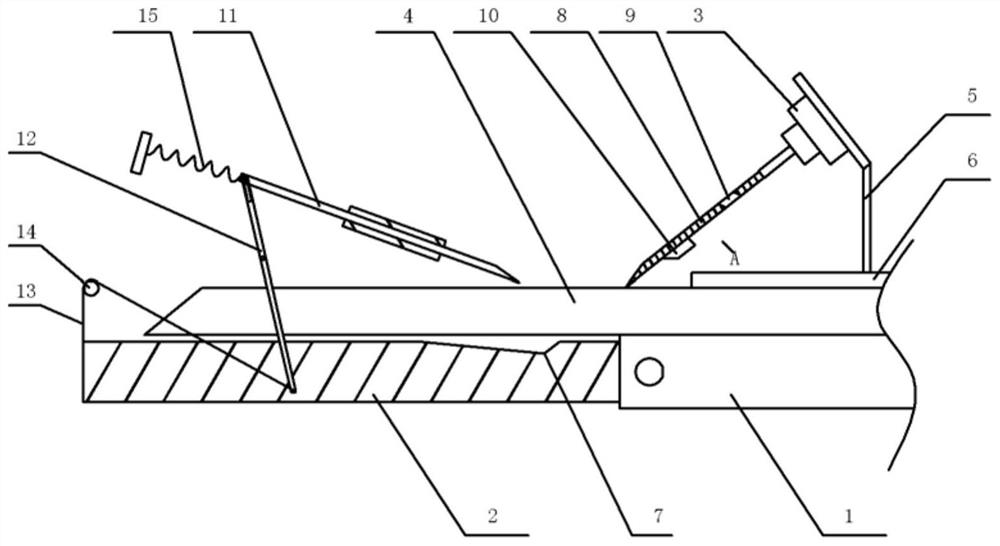

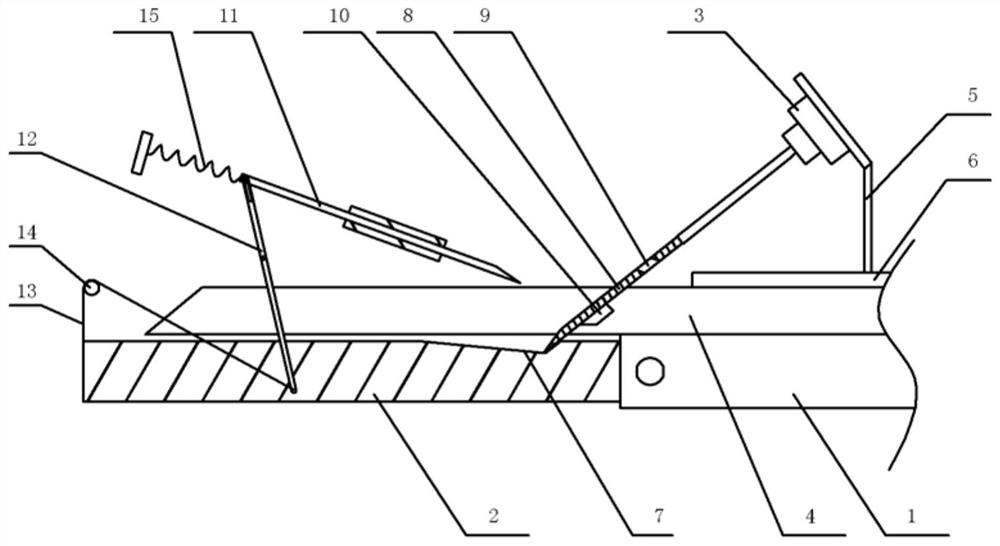

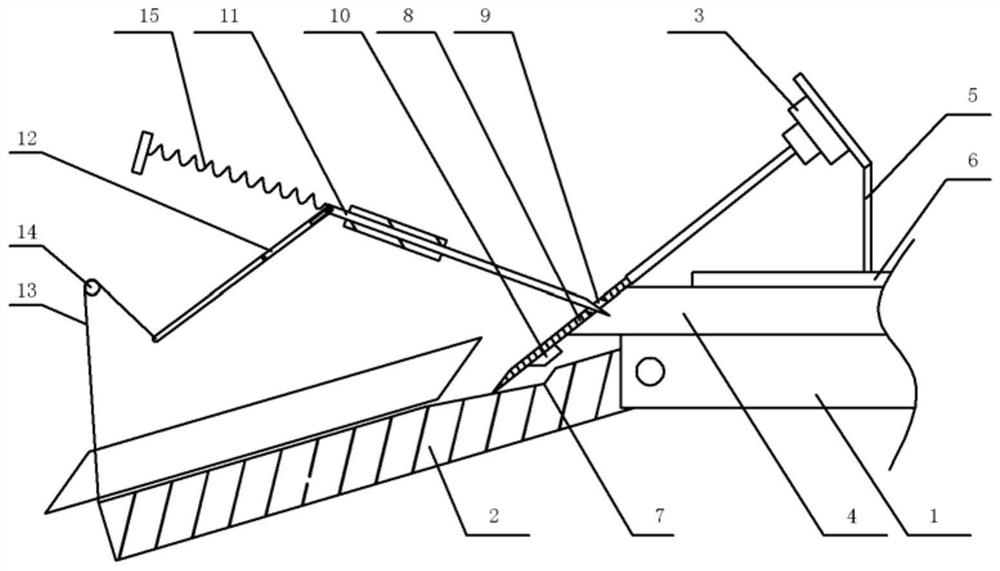

[0030] Step 3: Prepare a figure 1 The beef tendon slicing equipment shown includes a first support plate 1, a second support plate 2, a cylinder 3 and a layering mechanism, and the first support plate 1 is fixed on the frame, such as Figure 4 As shown, the right end of the second support plate 2 is hinged to the left end of the first support plate 1 through pins.

[0031] Such as figure 1 As shown, on the first support plate 1 and the second support plate 2, the cooked beef tendon 4 is placed, wherein the support rod 5 is...

Embodiment 2

[0041] The difference from Example 1 is that in step 1, prepare 40 g of beef ribs, 2 g of edible salt, 3 g of white sugar, 5 g of vegetable oil, 2 g of sesame, 2 g of pepper, 4 g of cumin, 1 g of spices and 2 g of food essence;

Embodiment 3

[0043] The difference from Example 1 is that in step 1, prepare 50 g of beef gluten, 5 g of edible salt, 4 g of white sugar, 10 g of vegetable oil, 4 g of sesame, 3 g of pepper, 6 g of cumin, 3 g of spices and 4 g of food essence.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com