Device used for screening waste battery materials and technology thereof

A waste battery and process technology, applied in battery recycling, recycling technology, waste collector recycling, etc., can solve the problems of exhaust gas pollution, low efficiency of recycling aluminum particles and black powder, and low automatic dismantling of power batteries , to achieve the effect of increasing the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

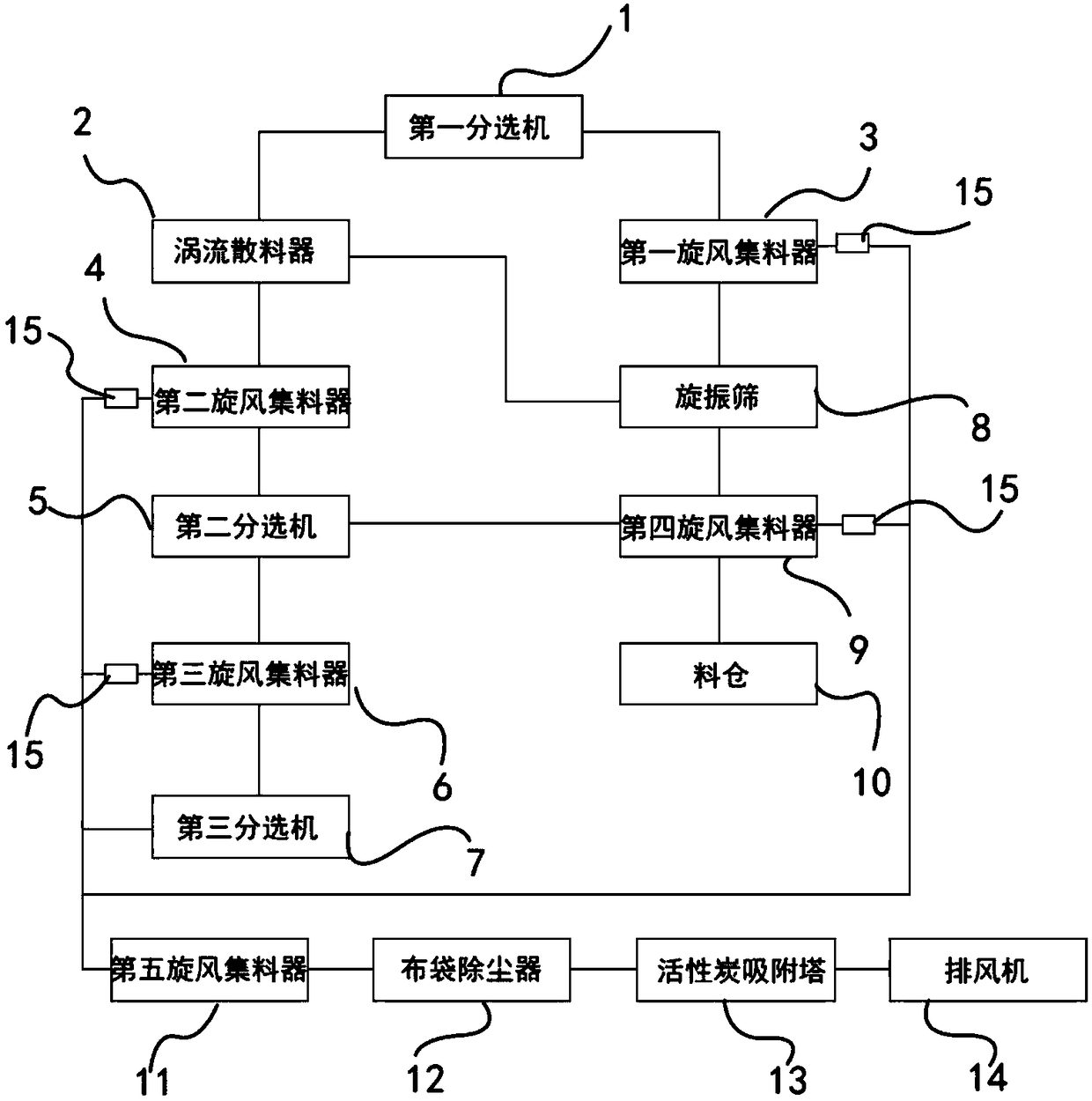

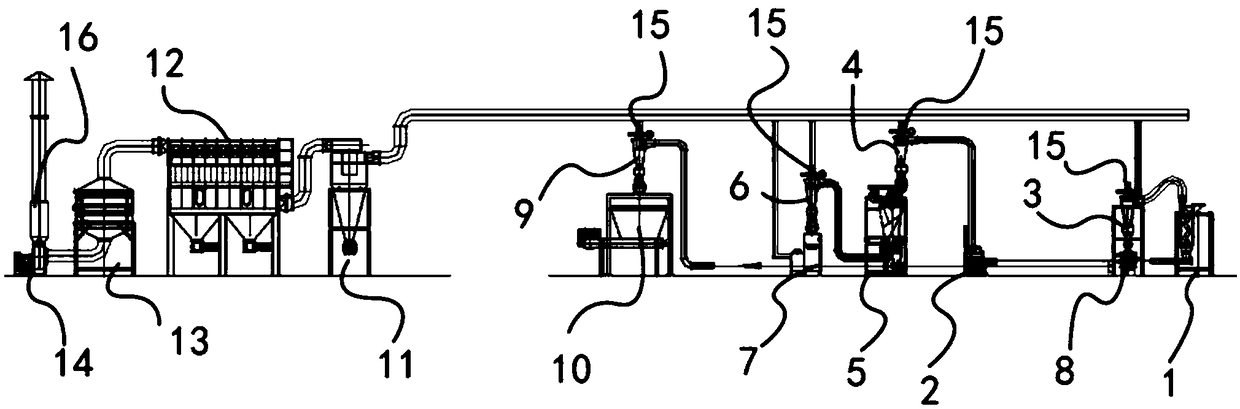

[0028] This embodiment provides a device for screening waste battery materials, such as figure 1 and figure 2 As shown, it comprises a first sorting machine 1, a discharge end of the first sorting machine 1 is communicated with a vortex bulking device 2 through a pipeline, and the other discharge end of the first sorting machine 1 is communicated with a second discharge end through a pipeline. A cyclone collector 3; the discharge end of the vortex bulk collector 2 is connected to the second cyclone collector 4, the second separator 5, the third cyclone collector 6 and the third separator 7 through pipelines in sequence , the discharge end of the first cyclone collector 3 is successively connected with the rotary vibrating screen 8, the fourth cyclone collector 9 and the feed bin 10 through the pipeline; the first cyclone collector 3, the second cyclone collector 4, The exhaust ends of the third cyclone collector 6 , the fourth cyclone collector 9 and the third separator 7 ar...

Embodiment 2

[0035] This embodiment also provides a process for screening waste battery materials by the device of Embodiment 1, which includes the following steps in sequence:

[0036] S1) The first sorting machine 1 screens the broken battery particles, the copper-aluminum mixture in the battery enters the vortex feeder 2 through the pipeline, and the film and black powder mixture in the battery enters the first cyclone collector through the pipeline 3 middle;

[0037] S2) The vortex bulking device 2 crushes the copper-aluminum mixture, and the broken copper-aluminum particles enter the second cyclone collector 4 and the second sorting machine 5 through the pipeline in turn, and the copper-aluminum particles screened by the second sorting machine 5 The particles enter the third cyclone collector 6 through the pipeline, and the third cyclone collector 6 screens clean copper and aluminum particles, and the clean copper and aluminum particles enter the third sorting machine 7 through the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com