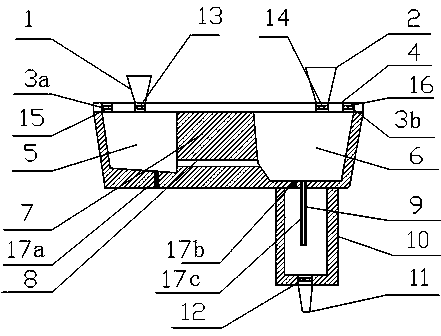

Channel-type middle bag and temperature increase preheating method thereof

A tundish and channel-type technology, which is applied in the direction of casting melt containers, metal processing equipment, casting equipment, etc., can solve the lack of adjustment and control functions of the tundish, the long distance between the channels on both sides of the tundish, and the long distance between the nozzles of the tundish, etc. problems, to avoid thermal stress cracking and deformation, to protect uniformity, and to prevent atmospheric backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In the early stage of preheating, open the preheating burner valve of the steel cavity and the preheating burner valve of the pouring steel cavity for combustion preheating, and simultaneously open the cover plate of the flue gas outlet of the steel cavity and the cover plate of the flue gas outlet of the pouring steel cavity. Open the valve of the induced draft fan, so that the refractory materials in the tundish are in the pre-baking stage. At this time, the preheated combustion flue gas is discharged from the flue gas exit hole of the bearing steel cavity, the delayed exit hole of the pouring steel cavity, and the induced draft fan.

[0032] During the preheating process, the temperature of the refractory material in the steel chamber is 150°C lower than that of the refractory material in the steel chamber and nozzle. The valve flow rate of the preheating burner valve of Dacheng steel cavity, after 20 minutes of preheating, the temperature of the three is less than 10...

Embodiment 2

[0035] In the early stage of preheating, open the preheating burner valve of the steel cavity and the preheating burner valve of the pouring steel cavity for combustion preheating, and simultaneously open the cover plate of the flue gas outlet of the steel cavity and the cover plate of the flue gas outlet of the pouring steel cavity. Open the valve of the induced draft fan, so that the refractory materials in the tundish are in the pre-baking stage. At this time, the preheated combustion flue gas is discharged from the flue gas exit hole of the bearing steel cavity, the delayed exit hole of the pouring steel cavity, and the induced draft fan.

[0036] During the preheating process, the temperature of the refractory material in the steel chamber is 200°C lower than that of the refractory material in the steel chamber and nozzle. Preheat the flow rate of the burner valve in the steel cavity. After 30 minutes of preheating, the temperature of the three is less than 80°C.

[0037]...

Embodiment 3

[0039] In the early stage of preheating, open the preheating burner valve of the steel cavity and the preheating burner valve of the pouring steel cavity for combustion preheating, and simultaneously open the cover plate of the flue gas outlet of the steel cavity and the cover plate of the flue gas outlet of the pouring steel cavity. Open the valve of the induced draft fan, so that the refractory materials in the tundish are in the pre-baking stage. At this time, the preheated combustion flue gas is discharged from the flue gas exit hole of the bearing steel cavity, the delayed exit hole of the pouring steel cavity, and the induced draft fan.

[0040] During the preheating process, the refractory material temperature of the pouring steel cavity is 120°C lower than the refractory material temperature of the pouring steel cavity and nozzle. Preheat the flow rate of the burner valve in the pouring cavity, and after 18 minutes of preheating, the measured temperature of the three is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com