Circular hole processing method

A processing method and round hole technology, applied in the field of round hole processing, can solve the problems of cumbersome processing process, unfavorable rapid processing, large drill damage, etc., and achieve the effects of avoiding drill damage, improving processing efficiency and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

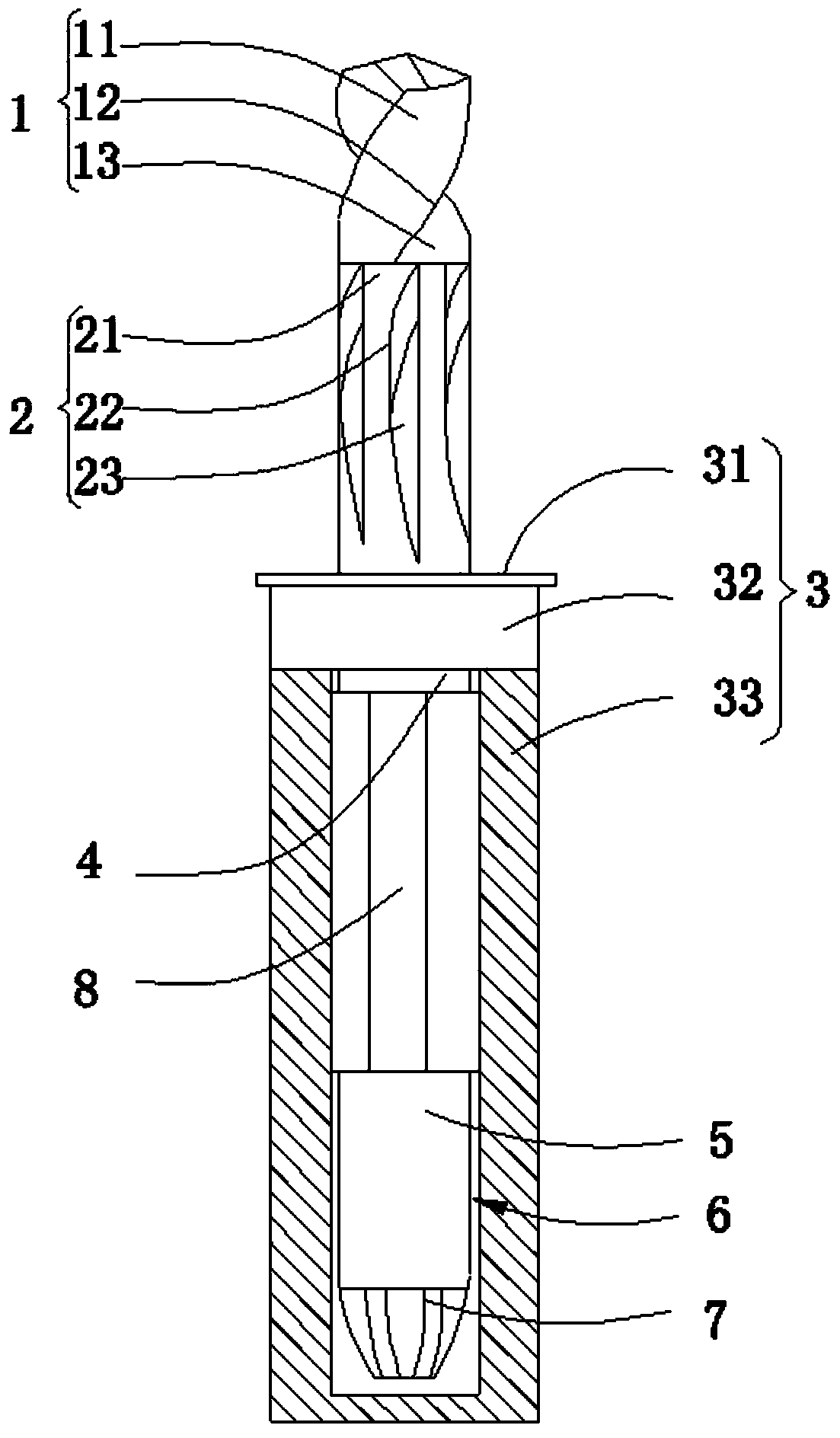

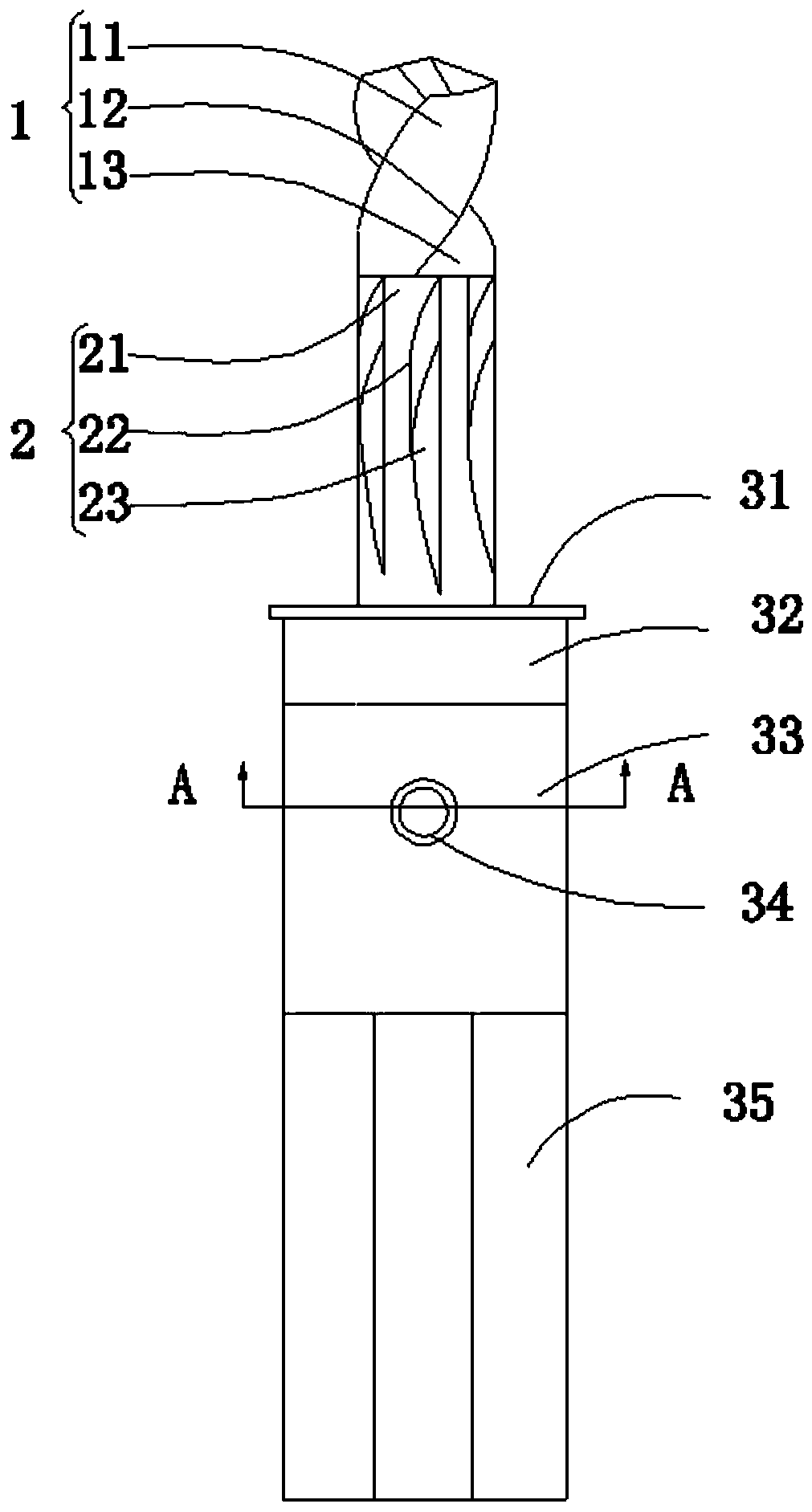

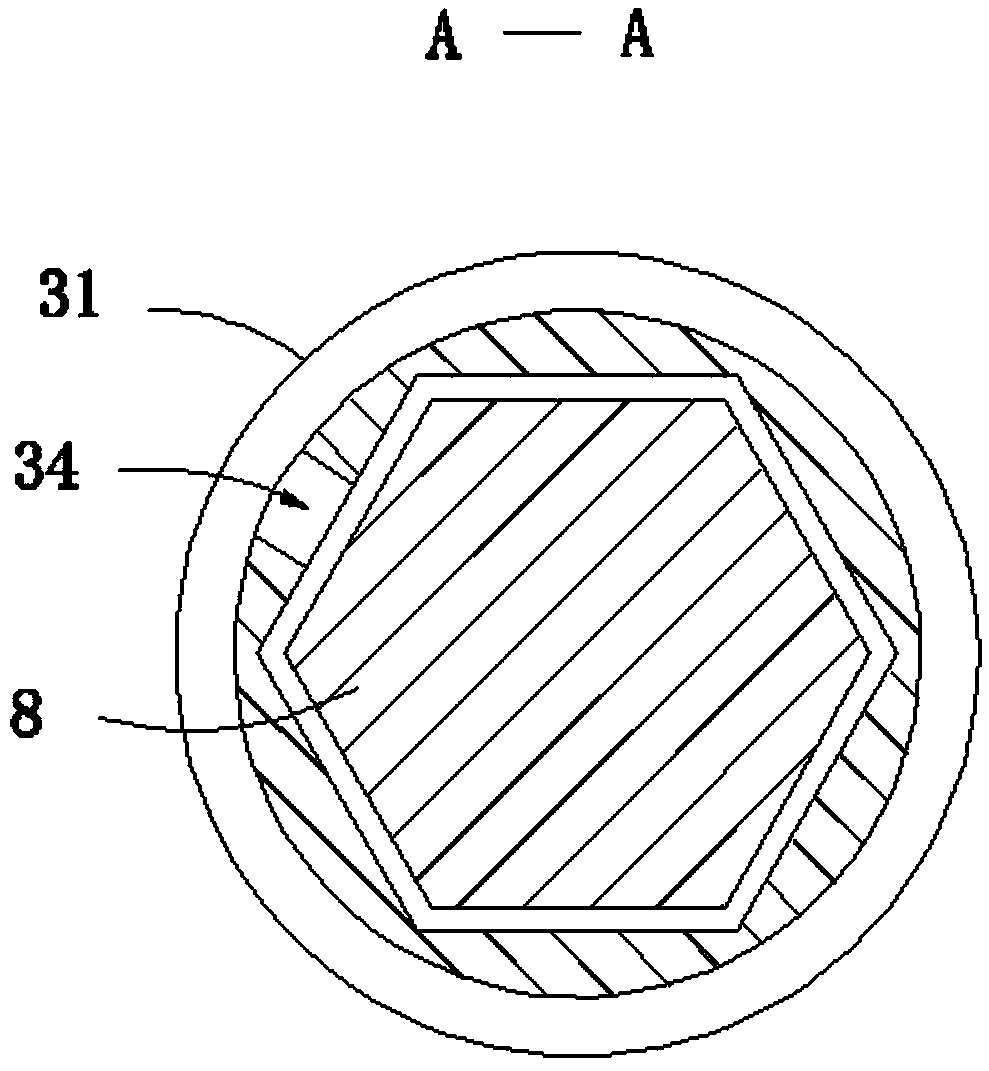

[0026] Such as Figure 1-4 Shown, a kind of round hole processing method of the present invention, this method comprises the following steps:

[0027] S1, use the laser to drill holes on the workpiece where holes need to be drilled to form laser holes;

[0028] S2, using the drill bit of the drilling machine to expand the hole along the laser hole in S1;

[0029] S3, using a multi-head reamer to ream the through hole in S2;

[0030] After S4 and S3 are completed, the workpiece is transported to the next process;

[0031] The multi-head reamer that adopts in this method comprises the first cutter head 1 that carries out cylindrical hole preprocessing, the second cutter head 2 that described first cutter head 1 is further processed, the 3rd cutte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com