Crossing operation abrasive disk structure and operation method thereof

A technology of grinding discs and grinding discs, applied in grinding tools, grinding machines, manufacturing tools, etc., can solve the problems of indistinguishable, insufficient reliability, and inconvenient replacement, and achieve the effect of improving grinding efficiency, improving replacement efficiency, and facilitating replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

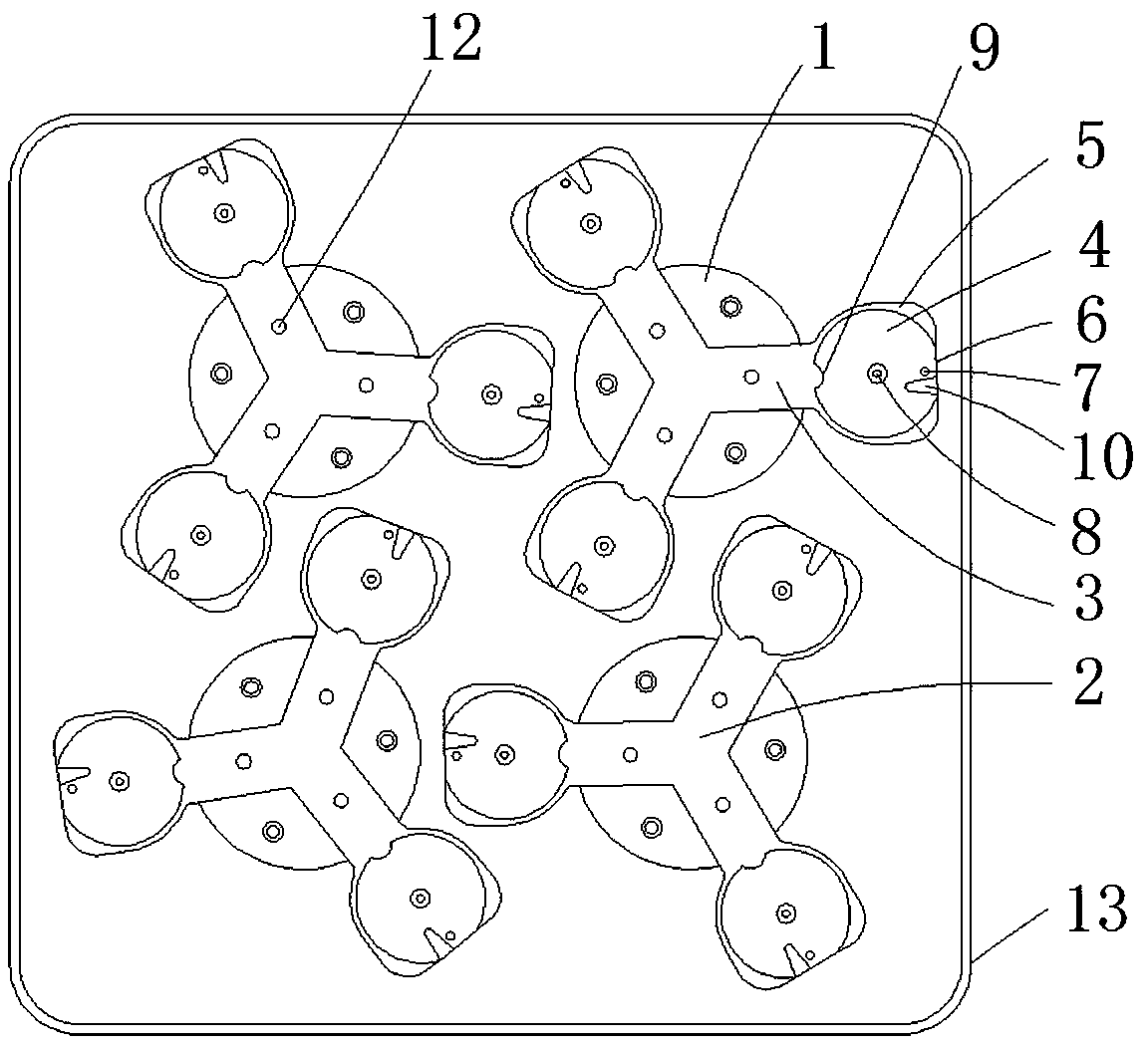

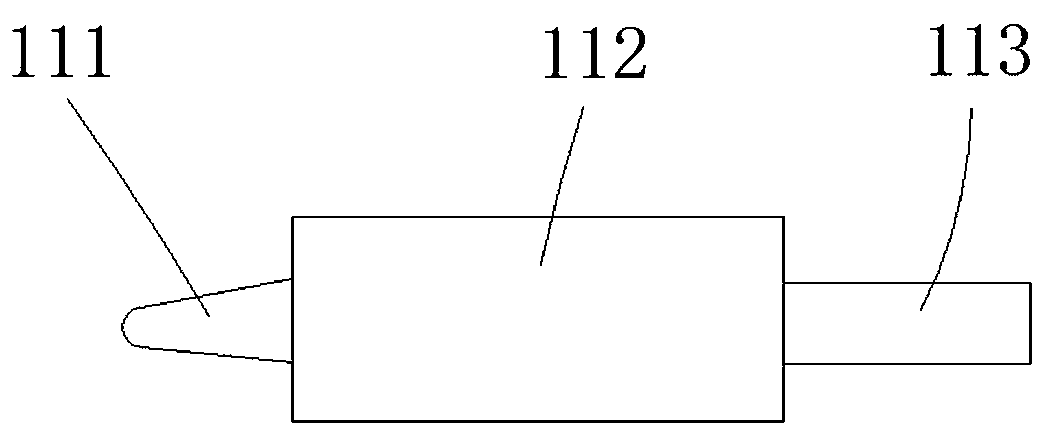

[0027] A cross-rotating millstone structure of the present invention, such as figure 1 and figure 2 As shown, it includes a set of rotating parts 1 in a rectangular array and a set of grinding discs 2 mounted on the rotating parts 1. The grinding discs 2 include a set of claws 3 in an annular array, and the claws 3 of adjacent grinding discs 2 are staggered. Setting, the end of the claw portion 3 is provided with a grinding plate installation disc 4, and the outer periphery of the grinding disc mounting disc 4 is provided with a raised wall 5, and the wall 5 is provided with a gap 6 at the end far away from the central axis of rotation of the grinding disc 2 , and, the bottom of the grinding disc mounting disc 4 is provided with a convex hull 7 at one end away from the central axis of rotation of the grinding disc 2, and the grinding disc installed in the grinding disc mounting disc 4 is provided with an escape portion corresponding to the convex protrusion 7, so A pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com