Suspended type railway vehicle

A rail vehicle and suspension technology, which is applied in the field of rail transit, can solve problems such as inconvenience, and achieve the effects of simple structure, convenient handling of people getting on and off and faults, and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

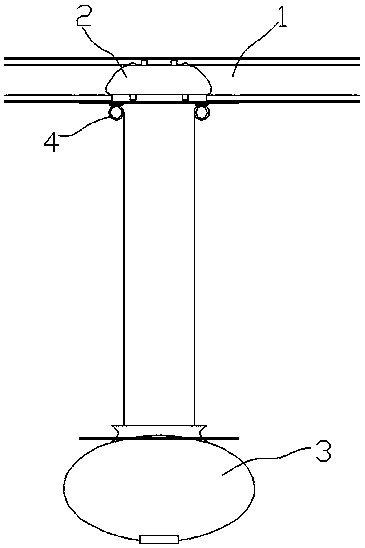

[0031] Such as figure 1 The suspended rail vehicle shown includes a running gear 2 on a track 1, and a car body 3 is connected with a lifting mechanism below the running gear 2, so that people only need to lower the car body when getting on and off and troubleshooting. The lifting mechanism includes a power unit 4 capable of making the car body lift. The upper end of the power unit 4 is connected to the running mechanism 2 and the lower end is connected to the car body 3 . The power unit 4 is a hoist, and the hoist is arranged on the bottom of the running mechanism 2, and the end of the steel cable in the hoist is connected with the car body 3. Above-mentioned winch also can replace with hydraulic cylinder, and hydraulic cylinder can make car body 3 lifting as power equally.

Embodiment 2

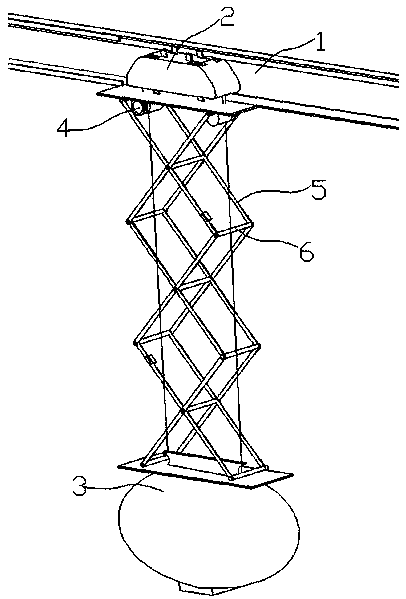

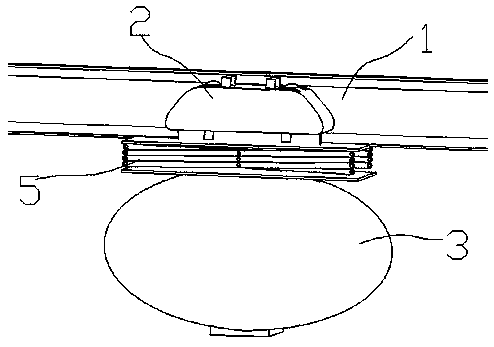

[0033] Such as figure 2 and image 3 As shown, in this embodiment, on the basis of Embodiment 1, an anti-sway stabilizing device is connected between the running mechanism 2 and the car body 3, and the anti-swaying stabilizing device is mainly composed of two parallel telescopic grids 5, The upper ends of the two telescopic grids 5 are connected to the running mechanism 2, and the lower ends are connected to the car body 3. The nodes of the two telescopic grids 5 correspond to each other, and a cross bar 6 is connected between the corresponding two nodes. The two ends pass through two corresponding nodes, and can also be rotated at the nodes, so that the device can not only expand and contract, but also the telescopic grid can prevent wind in the longitudinal direction, and the crossbar can play the role of lateral support, so that it achieves a relatively Good windproof and anti-shake effect.

Embodiment 3

[0035] Such as Figure 4 As shown, in this embodiment, on the basis of Embodiment 1, an anti-sway stabilizing device is connected between the traveling mechanism 2 and the vehicle body 3. The anti-swaying stabilizing device includes four sets of slide plates 7, and the four sets of slide plates 7 are respectively arranged on Around the car body 3, each group of slide plates 7 includes at least two, and the numbers are equal.

[0036] Such as Figure 5 As shown, the rear side of the slide plate 7 is provided with an inwardly recessed longitudinal chute 72, and the front side is provided with a slider 71, as Figure 6 Shown, the slide block 71 of the last slide plate can slide in the chute 72 of the previous slide plate, the upper end of the front slide plate 7 is connected with the running gear 2, and the lower end of the last slide plate 7 is connected with the car body 3. The design of four sets of skateboards also makes it better for windproof and anti-shake effect. The u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com