Cutting device for airtight encapsulation of quartz glass

A quartz glass and cutting device technology, applied in glass cutting devices, glass manufacturing equipment, cleaning methods using liquids, etc., can solve problems such as personal health hazards, glass plate detection angle adjustment, operator personal injury, etc., to reduce environmental pollution Pollution, improve work efficiency, and ensure the effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

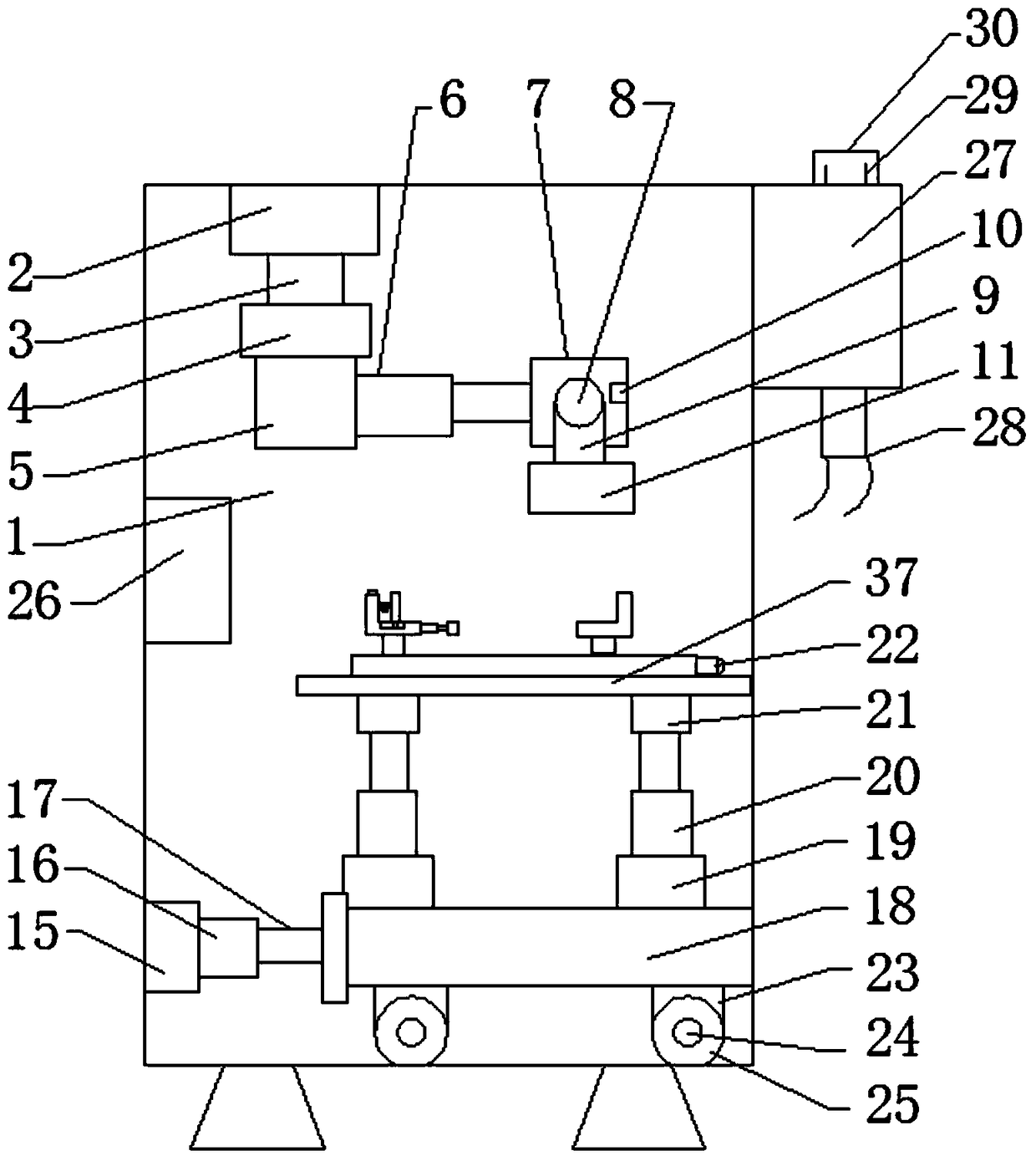

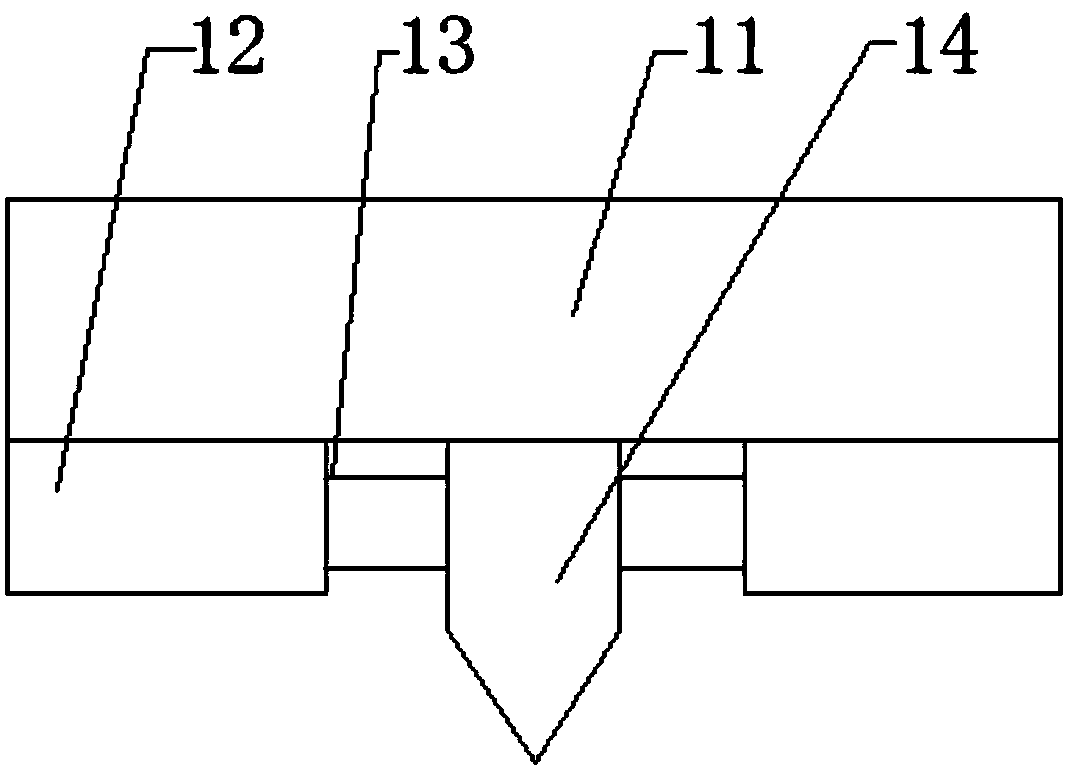

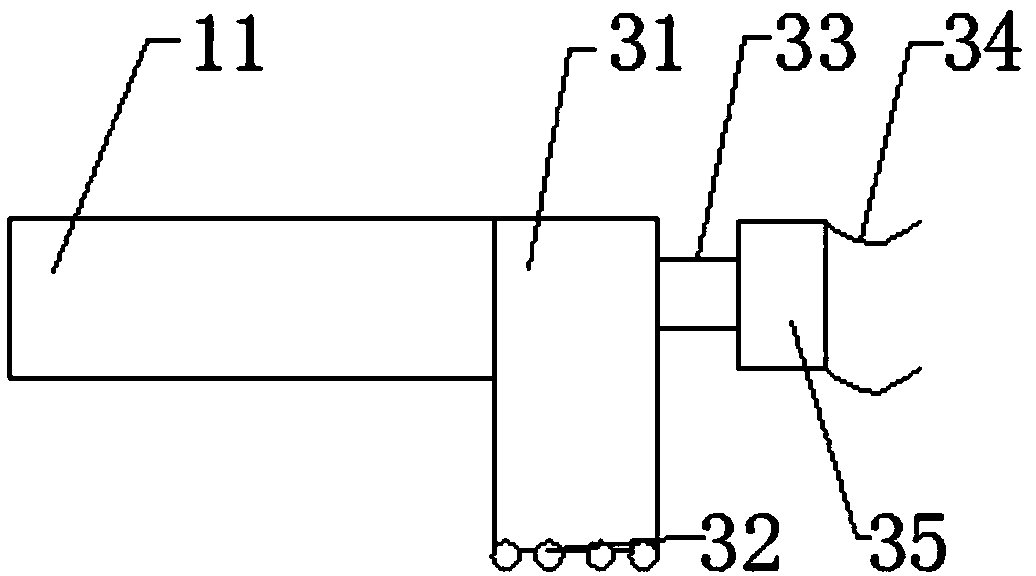

[0024] The present invention provides such Figure 1-6 The shown cutting device for hermetically sealing quartz glass includes a frame body 1, on which a cutter mechanism is arranged, and the cutter mechanism is fixedly installed under a fixer 7 The cutter holder 11 on the surface, the telescopic cylinder 12 fixedly installed on both sides of the lower surface of the cutter holder 11, the telescopic head 13 fixedly installed on one side of the telescopic cylinder 12, located at the lower end of the cutter holder 11 and connected with the telescopic head 13 The glass cutter 14 jointly constitutes, the frame body 1 is provided with a glass placement mechanism, and the glass placement mechanism consists of a linear motor 2 15 fixedly installed on one side of the frame body 1, and a linear motor 2 fixedly installed on the side of the frame body 1. The telescopic rod two 16 on one side of 15, the fixer two 17 fixedly installed on one side of the telescopic rod two 16, the horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com