Heap sprayed concrete rapid wall constructing method for coal mine underground

A technology of concrete and concrete admixture, which is applied in the direction of earth square drilling, mining equipment, mining equipment, etc., can solve the problems of inability to form effective roof support, insufficient strength, and small application range, so as to reduce labor intensity and cost of workers The effect of low and liberating labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

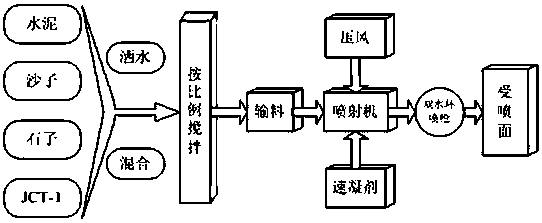

[0039] A method for rapidly building a wall with shotcrete for underground coal mines, comprising the following steps:

[0040] The first step is to knock on the roof to remove the living gangue in the roof area of the designed and constructed wall of the coal mine, remove the scum of the bottom plate in the designed wall area and find the hard bottom;

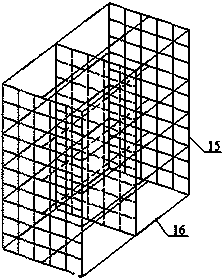

[0041] The second step is to place prefabricated reinforcement cages within the scope of the wall, and tie and connect the reinforcement cages with 16# tying wires; the width of the reinforcement cages is consistent with the width of the wall to control the forming size of the walls; the height and length of the reinforcement cages Equal to the height and length of the designed wall;

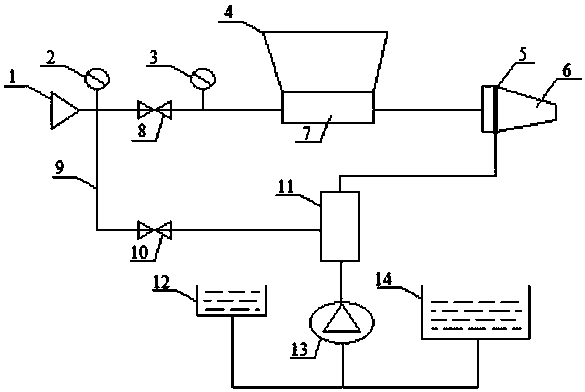

[0042] In the third step, according to the volume of the concrete wall constructed by the underground spraying, the raw materials of the spraying concrete are prepared on the ground according to the mass ratio of cement: sand: gravel: JCT-1 sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com