Vision-based plate surface detecting method

A surface inspection and plate technology, which is applied in the field of vision-based plate surface inspection, can solve problems such as a large number of waste products, complex production processes, and visual fatigue of employees, so as to reduce the production cost of enterprises, improve production efficiency, and reduce the effect of personnel misjudgment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

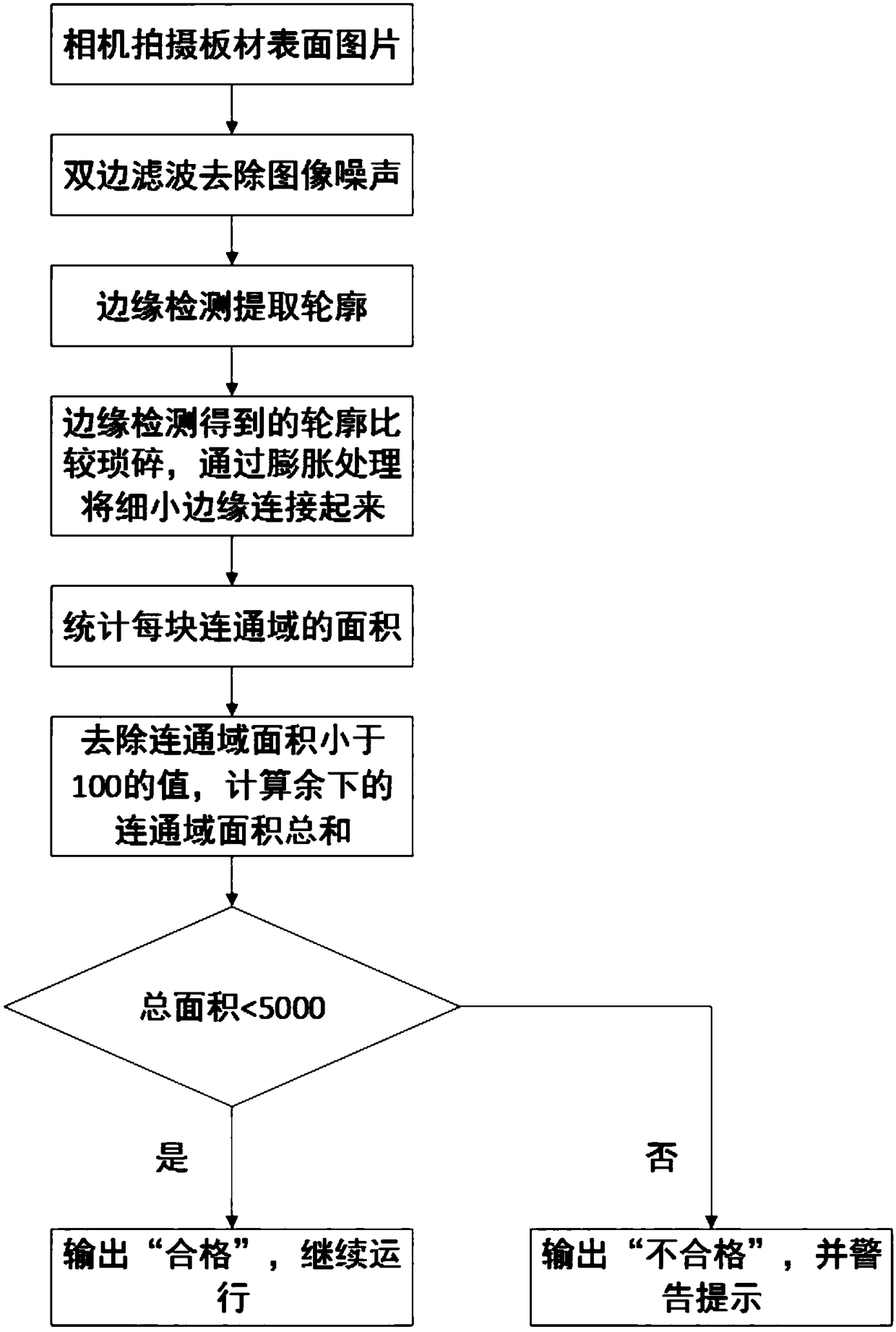

[0050] Such as Figure 1 to Figure 6 As shown, a vision-based plate surface detection method includes the following steps:

[0051] 101) The step of obtaining the extrusion molding image: obtaining the original grayscale image of the foam sheet to be tested. That is, the camera is placed on the upper part of the foam board to be tested through an external mechanical frame, 1.5 meters away from the formed foam board, for image generation and acquisition.

[0052] 102) Image preprocessing step: perform bilateral filtering processing of non-linear filtering on the image obtained in step 101), so as to not only preserve the edge information of the image, but also achieve the effect of denoising. Bilateral filtering is a compromise process that combines the spatial proximity of the image and the similarity of pixel values. At the same time, it considers the spatial information and gray similarity, which can not only preserve the edge information of the image, but also achieve the ...

Embodiment 2

[0064] Such as figure 1 As shown, a vision-based plate surface detection method includes the following steps:

[0065] 101) The step of obtaining the extrusion molding image: the camera is placed on the upper part of the foam sheet to be tested through an external mechanical frame, 1 meter to 2 meters away from the formed foam sheet, and the image is generated to obtain the original grayscale image. Among them, the best distance from the foam board is 1.5 meters, because the detection at this position can not only cover the whole picture of the board, but also can see the surface information of the board to the greatest extent.

[0066] Its camera selection:

[0067] 1) Resolution calculation: The detection accuracy is set at 1mm. Since XPS boards are produced continuously, it is only necessary to set the width resolution. The width of the XPS board is 680mm, so the field of view of the camera is set to 750mm, so the resolution in the width direction is 750. In practical app...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com