Output performance test method for stacked piezoelectric ceramic driver

A technology of piezoelectric ceramics and testing methods, which is applied in the field of performance testing of stacked piezoelectric ceramic drivers, can solve the problems of unknown output performance of stacked piezoelectric ceramic drivers, no testing methods for testing devices, etc., and achieve simple testing methods and high precision , Improve the effect of assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation of the present invention will be described in detail below in conjunction with the technical solution and the drawings.

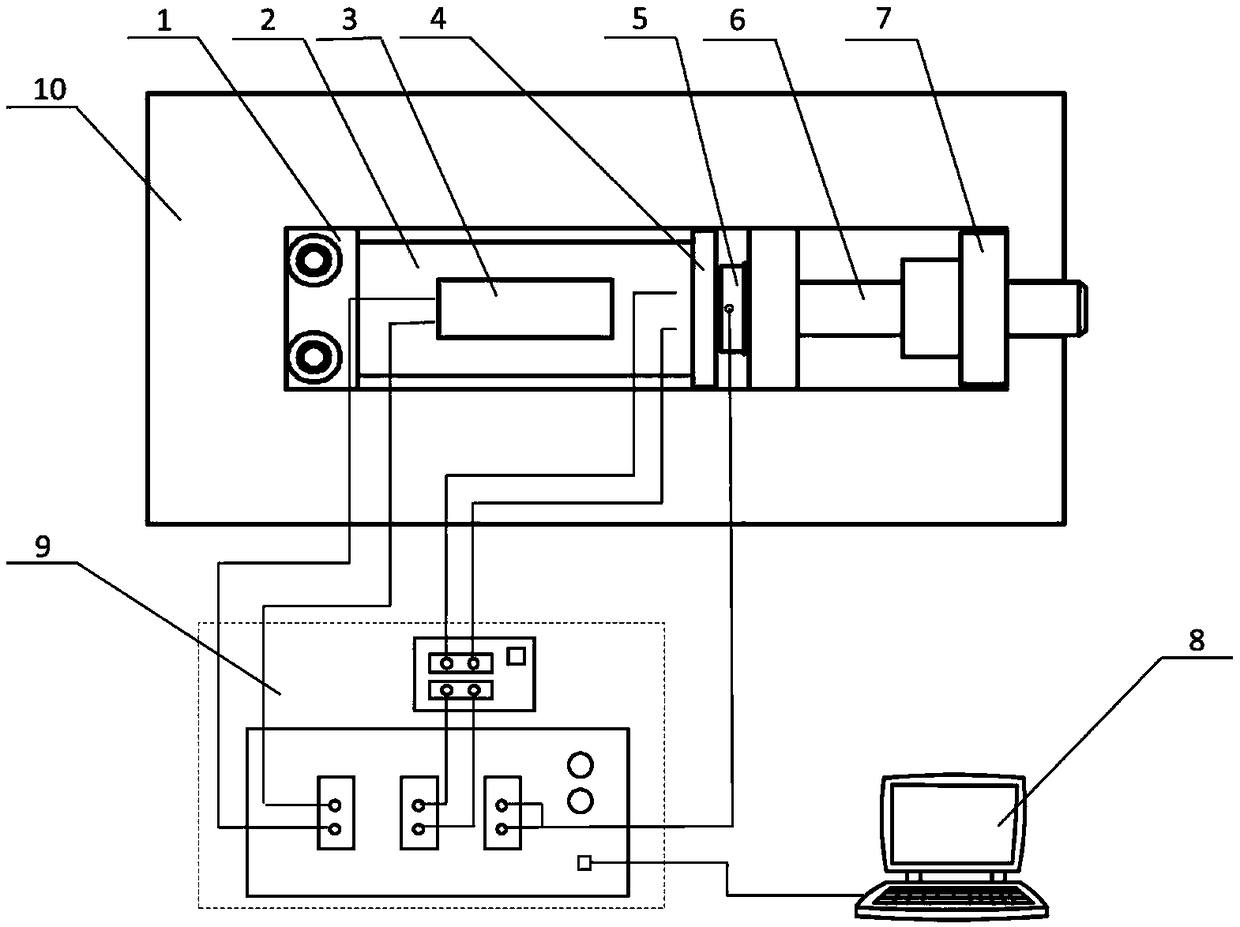

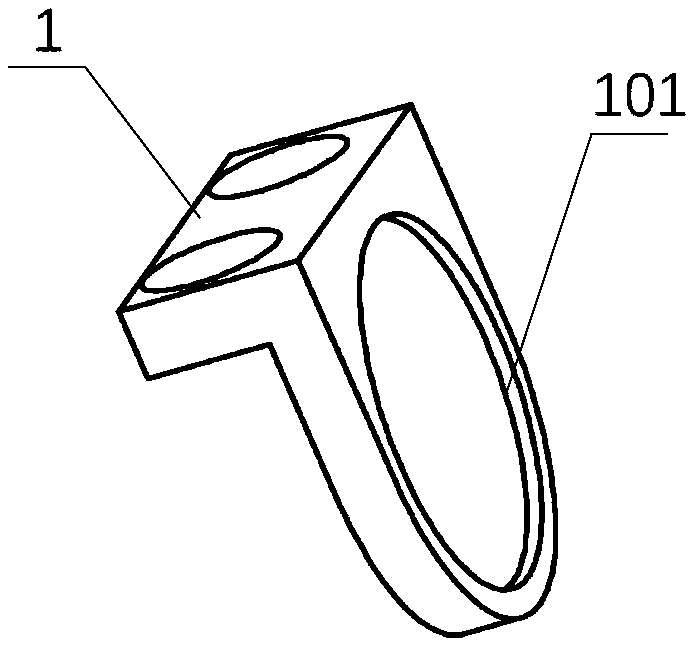

[0029] Such as figure 2 As shown, a stacked piezoelectric ceramic driver output performance test system for active vibration suppression struts in a wind tunnel consists of a base 10, a fixed tailstock 1, a stacked piezoelectric ceramic driver 2, a strain gauge 3, and a gasket 4. , Pressure sensor 5, push rod 6, fastening nut 7, computer 8, measurement control system 9.

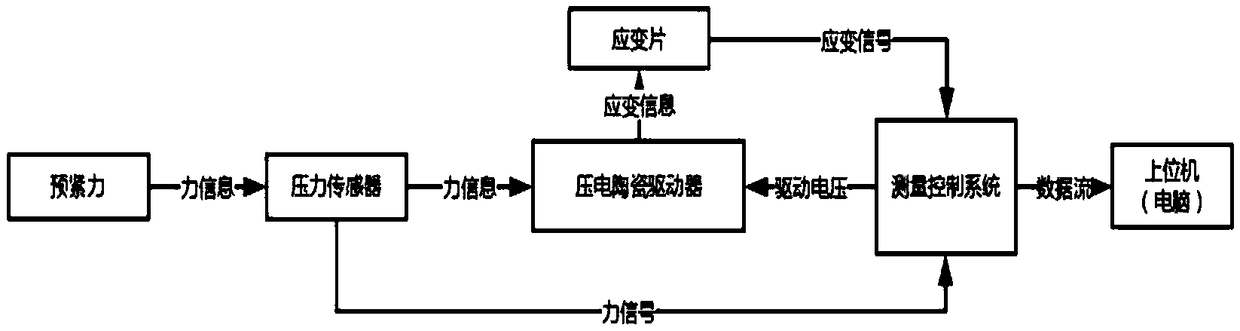

[0030] figure 1 It is the principle diagram of the test system of the present invention. Firstly, the pre-tightening force is given, the pressure sensor receives the force information, and it is sent to the stacked piezoelectric ceramic driver and the measurement control system. The measurement is measured by the strain gauge attached to the stacked piezoelectric ceramic driver The strain information is also sent to the measurement control system. At the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com