Mixed pumped alkali metal gas chamber density ratio control method

An alkali metal gas chamber and control method technology, applied in the direction of color/spectral characteristic measurement, etc., can solve the problems of high temperature and high pressure, difficult to achieve, harsh and complex conditions, etc., to achieve uniform heating temperature, high temperature control accuracy, and good control and measurement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

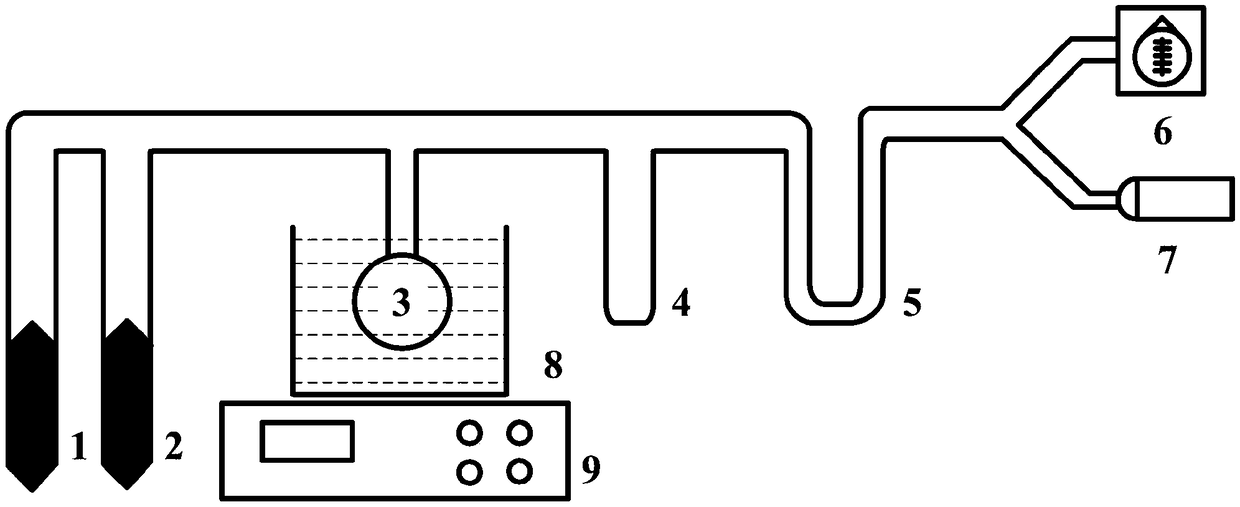

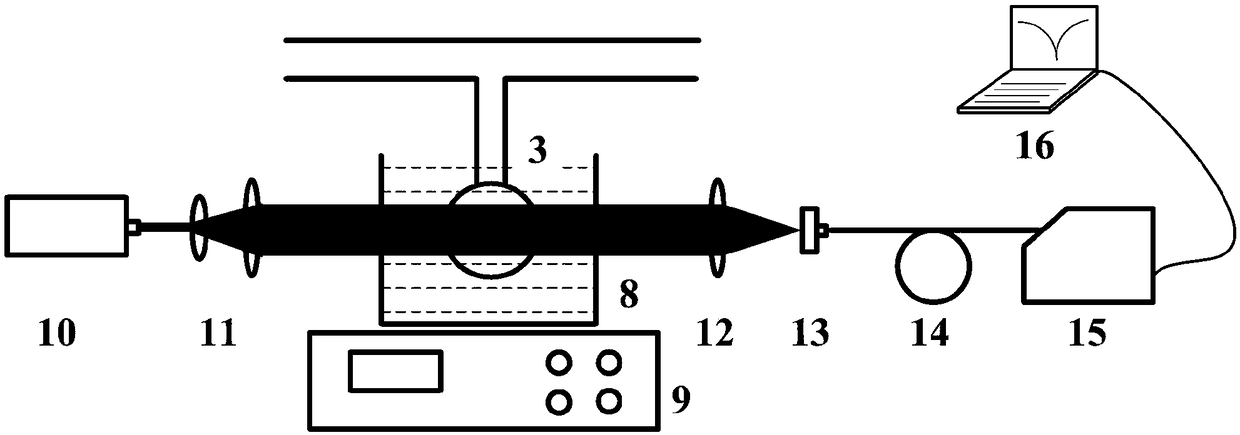

[0023] A method for controlling the density ratio of mixed pumped alkali metal gas chambers based on a distillation purification method. Using the method of distillation purification, the atomic weight of one alkali metal is controlled to change the atomic density ratio of the two alkali metals, and the density ratio is accurately controlled by combining the distillation temperature and the pumping speed of the molecular pump. The oil bath is used to control the distillation temperature, so that the temperature of the alkali metal gas chamber is more uniform and accurate. At the same time, the white light source is used to measure the spectral absorption of the alkali metal gas chamber, and the atomic density ratio of the alkali metal is calculated. This method is a method capable of on-line control and on-line measurement during the manufacturing process of the mixed pumped alkali metal gas chamber, which can greatly improve the accuracy of the density ratio of the mixed pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com