Multifunctional seeding, ripping and raking machine for fermentation bed

A fermentation bed and rake turner technology, applied in the field of rake turner, can solve the problems of unsatisfactory poultry manure effect, poultry manure pollution, high labor cost, etc., and achieve uniform output, reduce workload, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

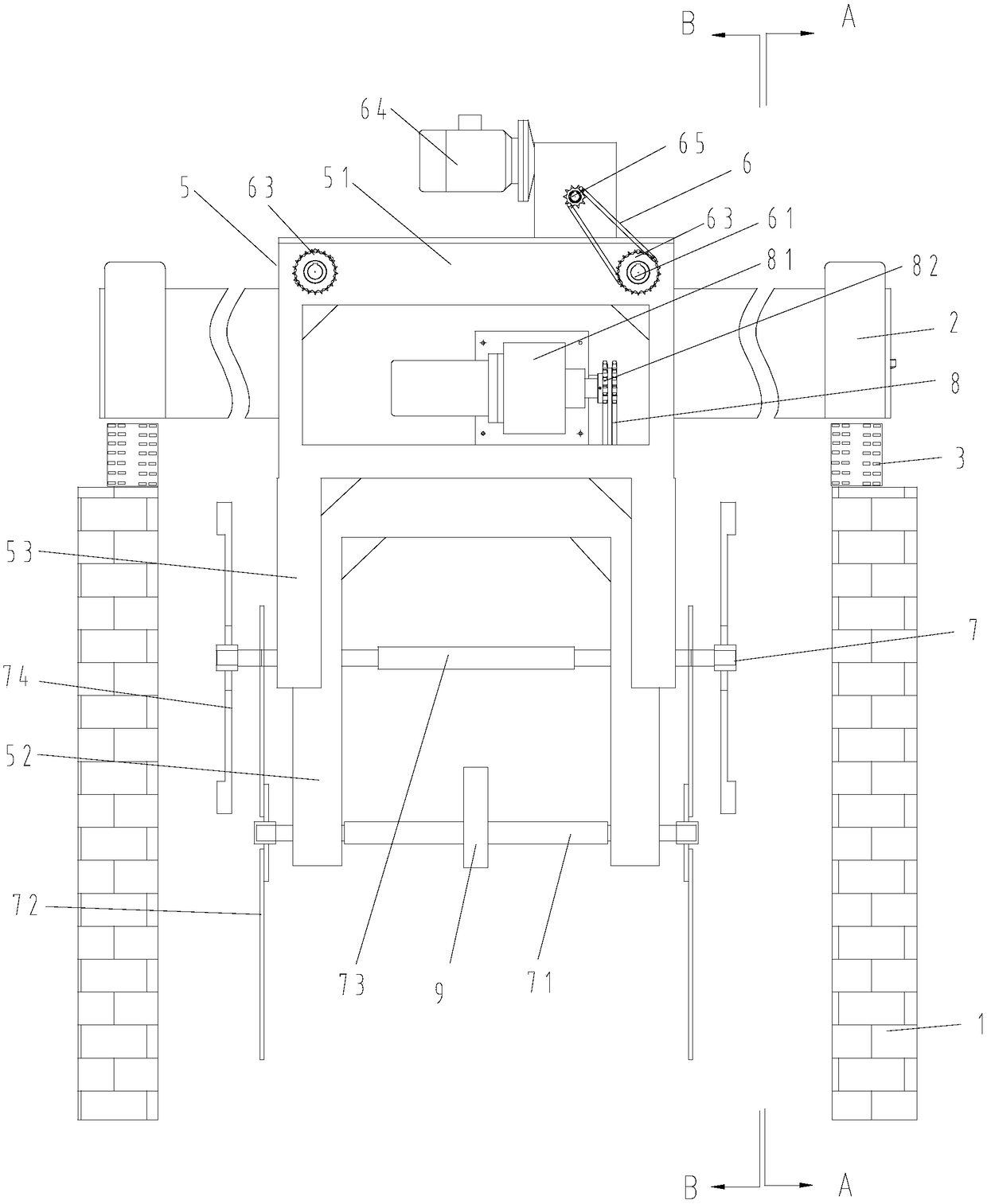

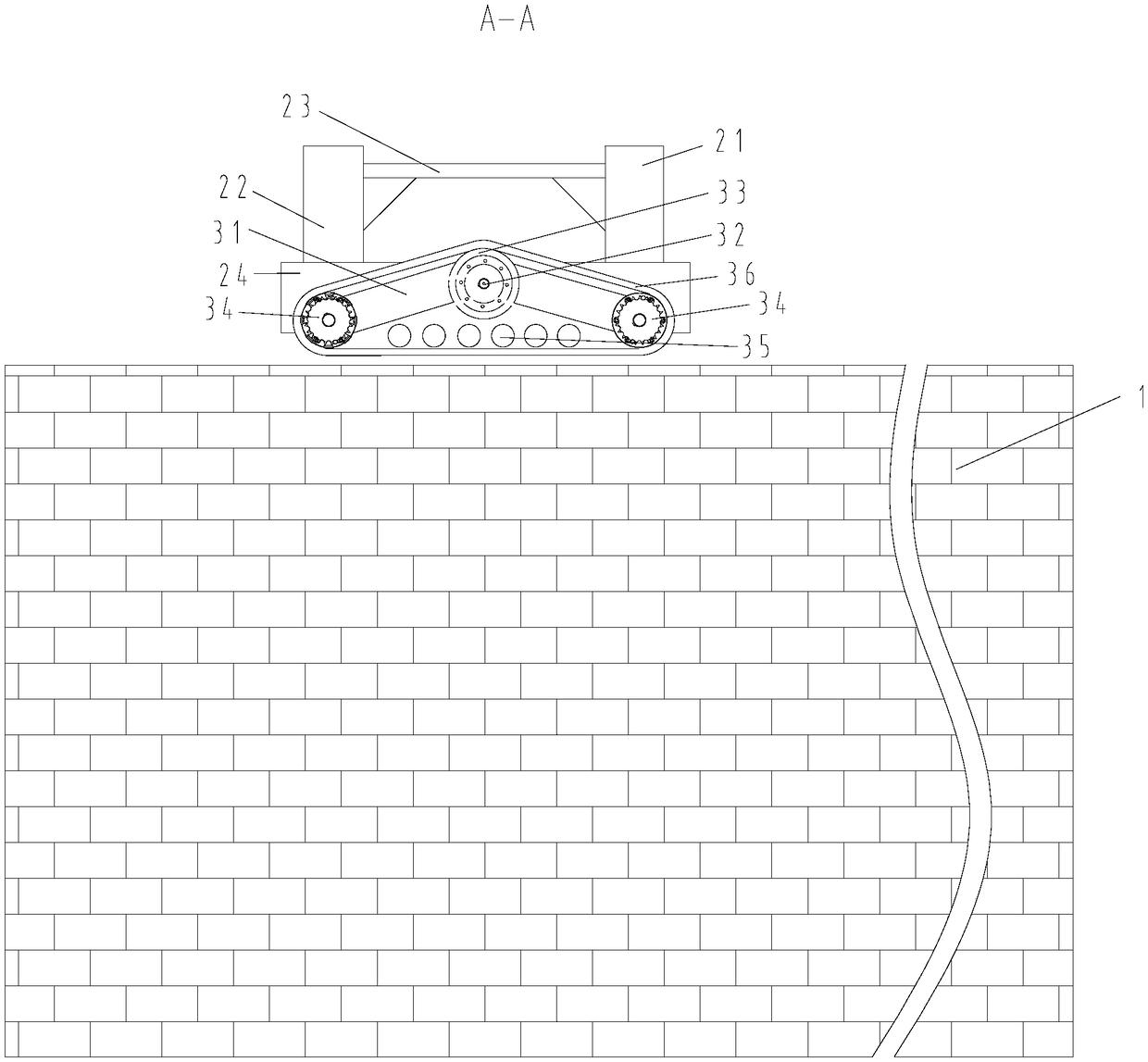

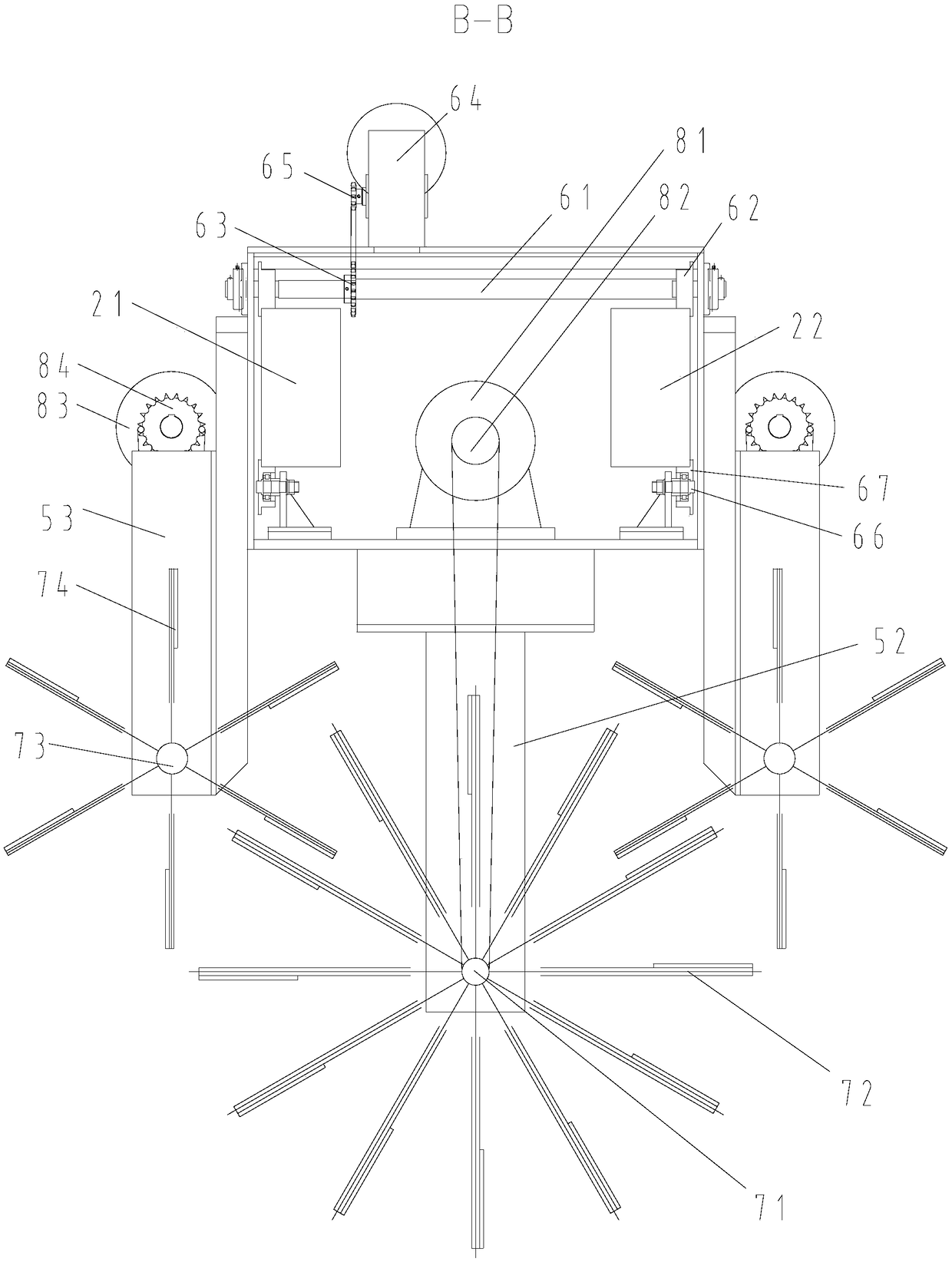

[0032] The content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments of the description:

[0033] Such as Figure 1-6As shown, the present embodiment provides an automatic sowing rake machine for a fermentation bed, including a longitudinal moving frame 2, a crawler wheel mechanism 3 for driving the longitudinal moving frame 2 to move longitudinally, and a crawler wheel mechanism 3 for controlling the longitudinal moving frame 2 on both lateral sides. A synchronously moving synchronous mechanism 4, a horizontally movable laterally movable frame 5 mounted on the longitudinally movable frame 2, a lateral drive mechanism 6 for driving the laterally movable frame 5 to move laterally on the longitudinally movable frame 2, and a horizontally movable frame mounted on the laterally movable frame The rake mechanism 7 on the 5, the rake drive mechanism 8 for driving the rake mechanism 7 to turn the rake, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com