An aluminum ingot quality inspection and transfer transport device

A technology of transportation device and aluminum ingot is applied in the field of aluminum product inspection and transfer device, which can solve the problems of affecting the quality inspection effect, large inspection error, lack of transfer transportation device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

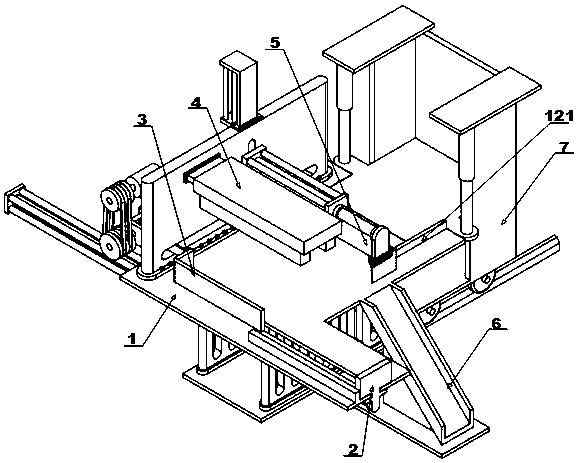

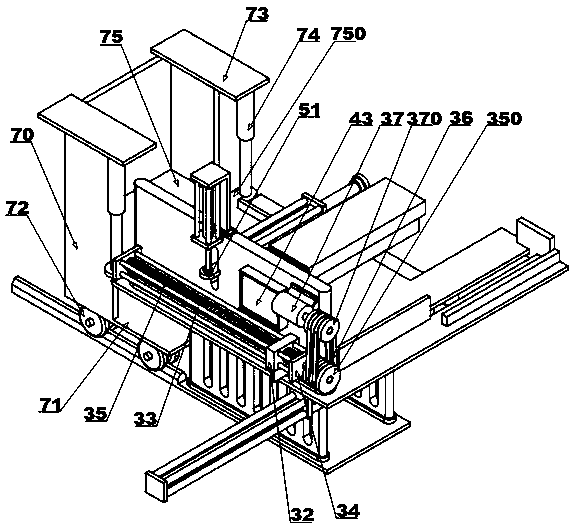

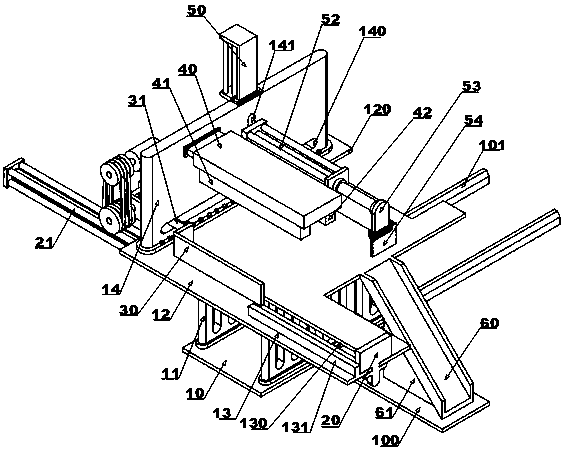

[0043] 1. After the casting and marking of the aluminum ingot is completed, it will enter the working plate 13 of the front pulling mechanism from the right side of the working plate 13 of the front pulling mechanism laterally, and the left long side of the aluminum ingot is close to the right side of the front pulling block 131;

[0044] 2. Start the front pulling cylinder 21, so that the front pulling plate 20 acts on the front end of the aluminum ingot, push the aluminum ingot into the push plate 30, and also ensure that the rear end of the aluminum ingot is close to the rear end of the push plate 30;

[0045] Three, start the motor 37, so that under the drive of the screw rod 35, the push plate 30 moves rapidly to the direction of the quality inspection mechanism 4;

[0046] 4. When the right side of the aluminum ingot is adjacent to the quality inspection mechanism 4, reduce the rotating speed of the motor 37, and then under the promotion of the push plate 30, the aluminum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com