Edge banding machine and bathroom cabinet plate edge banding method applied to edge banding machine

A bathroom cabinet and edge banding machine technology, applied in the field of wood panel edge banding, can solve the problems of unfavorable board cleanliness, easy accumulation of dust, large dispersion, etc., so as to improve the quality of lamination, improve the cleanliness, and improve the lamination effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

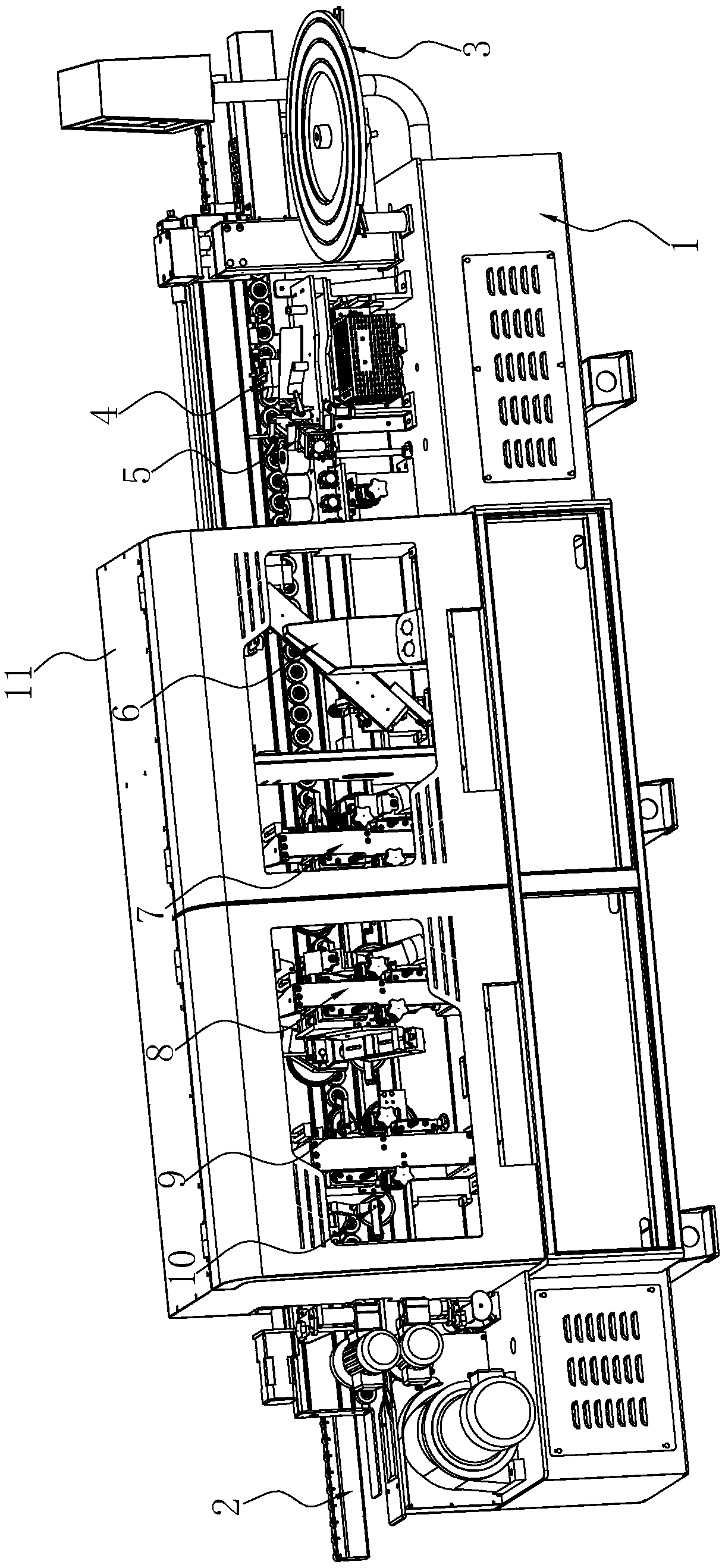

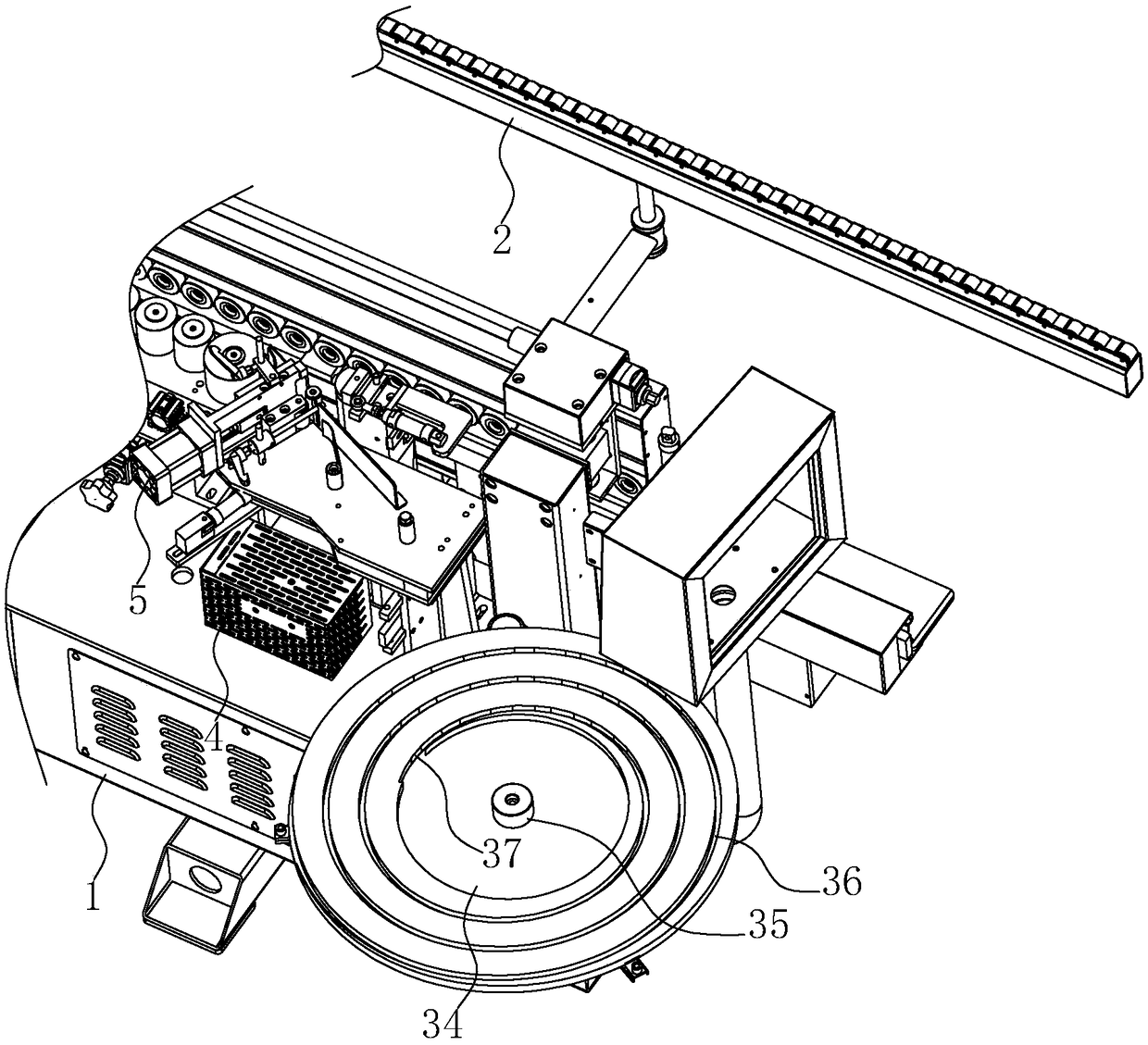

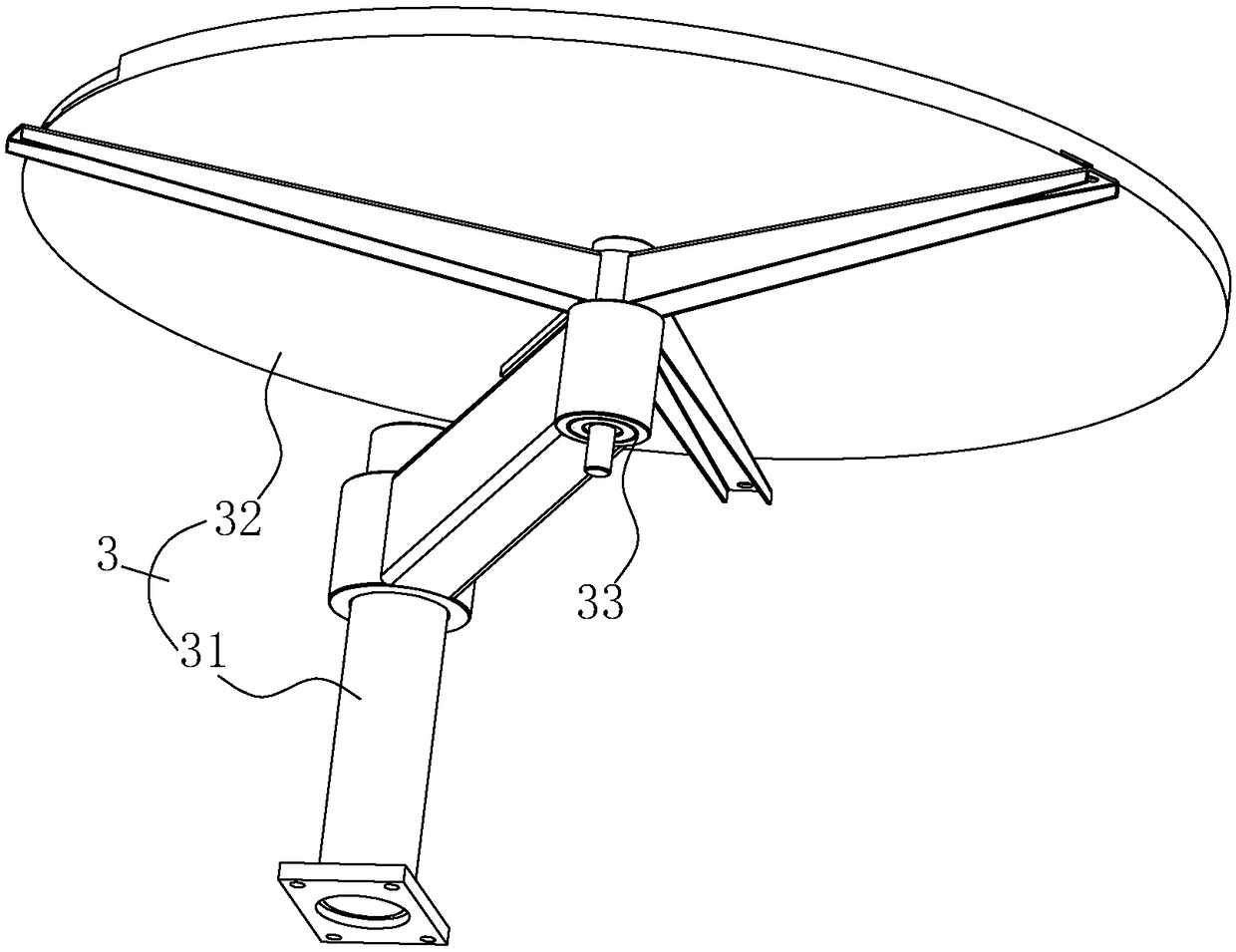

[0048] Embodiment 1, a kind of edge banding machine, such as figure 1 As shown, it includes a frame 1, a feeding belt 2, and a conveying mechanism 3, a gluing mechanism 4, a cutting and pressing mechanism 5, an edge trimming mechanism 6, a rough repair mechanism 7, a fine repair mechanism 8, a scraper Edge mechanism 9 and polishing mechanism 10. The feeding belt 2 is set along the length direction of the frame 1, the conveying mechanism 3, the gluing mechanism 4, the cutting and pressing mechanism 5, the edge trimming mechanism 6, the rough repairing mechanism 7, the finishing mechanism 8, the edge scraping mechanism 9 and the polishing mechanism 10 They are arranged side by side in turn on the frame 1 and are located on the other side adjacent to the feeding belt 2 . A dustproof box 11 is also provided on the frame 1, and the cutting and pressing mechanism 5, the edge trimming mechanism 6, the rough repair mechanism 7, the finishing mechanism 8, the edge scraping mechanism 9...

Embodiment 2

[0053] Embodiment 2, a bathroom cabinet board edge sealing method applied to the edge banding machine in embodiment 1, such as figure 1 , 6 As shown, including the following steps:

[0054] In the conveying process, the boards and strips to be edge-banded are transported to different processes in sequence along the conveying direction by the conveying mechanism 3 of the feeding belt 2, and the edge-banding processing operation is carried out;

[0055] In the cutting process, the edge banding strip to be bonded is cut by the cutting and pressing mechanism 5 according to the side length of the required edge banding plate, so as to ensure the edge banding effect and use the edge banding material reasonably;

[0056] In the process of gluing and wetting, the gluing mechanism 4 applies glue to the side of the panel to be edged, and the edge strip is cut to an appropriate length by the cutting and pressing mechanism 5, and then pressed against the edge of the panel for gluing ;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap