A feed packaging device

A feed and packaging bag technology, applied in the field of feed packaging equipment, can solve the problems of operator pneumoconiosis, unfavorable occupational health, and low packaging efficiency, and achieve the effects of reducing labor intensity, avoiding occupational health hazards, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

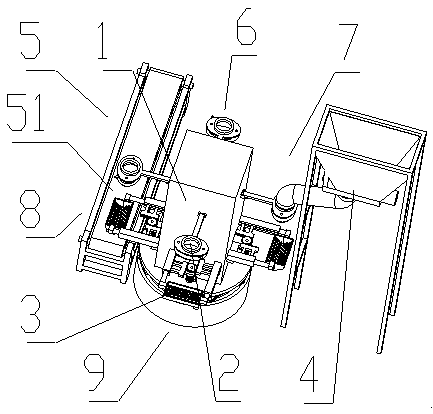

[0040] see Figure 1-7 , the embodiment of the present invention provides a feed packaging device, including a support mechanism 1, a feeding mechanism 4, a transfer mechanism 5, and four bag support mechanisms 2 and bag support mechanisms 3 arranged on the support mechanism 1, the bag support mechanism 2 is set above the bag holding mechanism 3;

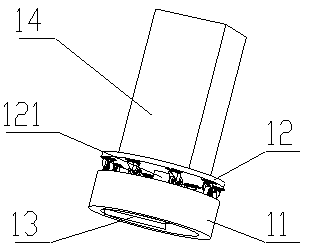

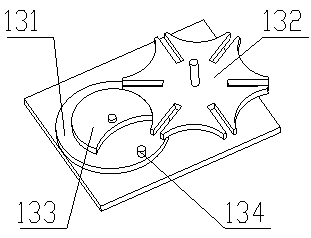

[0041] The support mechanism 1 includes an annular base 11, the annular base 11 is hollow cylindrical, the upper end of the annular base 11 is provided with a turntable 12, the lower part of the turntable 12 is provided with a cycle control unit 13, and the cycle control unit 13 drives the turntable 12 to rotate relative to the ring base 11, and the turntable 12. A column 14 is arranged at the center of the upper end surface;

[0042] The bag support mechanism 2 includes a support arm 21, a bag support tube 22 and an annular bag support air bag 23. One end of the support arm 21 is fixed on the side wall of the column 14, and the ot...

Embodiment 2

[0055] see Figure 1-7 , the embodiment of the present invention provides a method of filling feed using the feed packaging device of Embodiment 1. When the turntable 12 stops rotating, three positions of the bag-supporting mechanism 2 and the bag-holding mechanism 3 are provided, and according to the rotation of the turntable 12 The direction is set as bagging point 6, filling point 7 and transfer point 8 in turn, the operator is located at bagging point 6, the position of unloading mechanism 4 is filling point 7, and is located below the bag holding mechanism 3 on transfer point 8 A conveyor belt 51 is provided;

[0056] Specific steps are as follows:

[0057] Step 1. The operator puts the packaging bag on the bag support cylinder 22 located at the bagging point 6, and then presses the inflation control switch 28, and the ring-shaped bag support airbag 23 is inflated to prop up the opening of the packaging bag. Rotate, the operator continues to wrap the packaging bag on th...

Embodiment 3

[0061] see Figure 1-7 , the embodiment of the present invention provides a method of filling feed using the feed packaging device of Embodiment 1. When the turntable 12 stops rotating, four positions of the bag-supporting mechanism 2 and the bag-holding mechanism 3 are provided, and according to the rotation of the turntable 12 The directions are successively set to bagging point 6, filling point 7, sealing point 9 and transfer point 8, two operators are respectively located at bagging point 6 and sealing point 9, and the position of unloading mechanism 4 is filling point 7, A conveyor belt 51 is arranged below the bag holding mechanism 3 on the transfer point 8;

[0062] Specific steps are as follows:

[0063] Step 1. The operator puts the packaging bag on the bag support cylinder 22 located at the bagging point 6, and then presses the inflation control switch 28, and the ring-shaped bag support airbag 23 is inflated to prop up the opening of the packaging bag. Rotate, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com