A visual long-distance dense phase positive pressure pneumatic conveying test device

A technology of pneumatic conveying and testing equipment, which is applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc., and can solve problems such as no automatic blockage removal function, unfavorable conveying stability control, and large flow influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

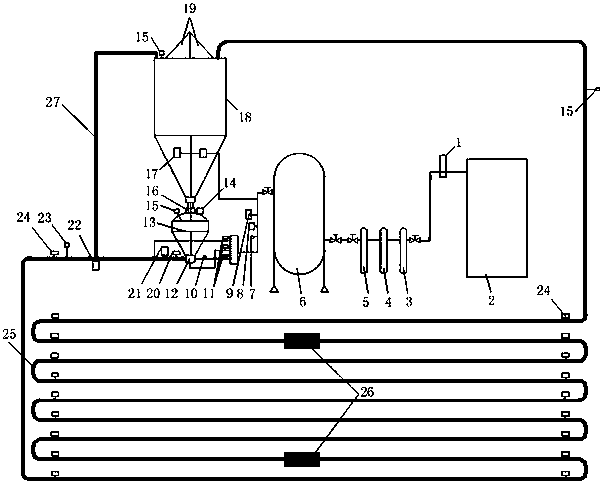

[0041] In this implementation example, the delivery pipeline has a diameter of DN100 and a length of 600 m as an example. Conduct visual long-distance dense-phase pneumatic conveying experiments.

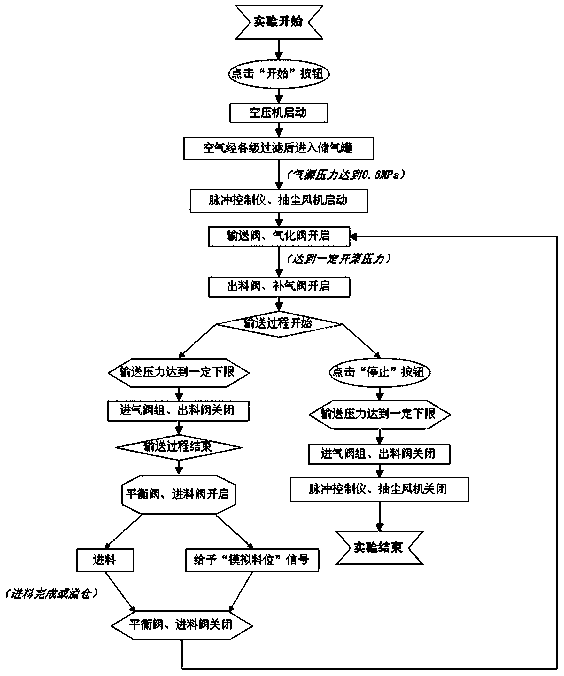

[0042] Such as figure 1 As shown, the experimental method using the described visual long-distance dense-phase positive pressure pneumatic conveying test device includes the following steps:

[0043] Step 1: Before the experiment, set the delivery pipeline 25 to a diameter of DN100 and a length of 600m; adjust one Ф8mm air intake hole and all 45 Ф3mm air intake holes of the porous orifice throttling device 10 to open up to obtain stable air Volumetric flow rate, check the running status of the air compressor and the tightness of the air storage tank and various valves.

[0044] Step 2: Start the air compressor to compress the air so that the pressure in the air storage tank reaches above 0.5MPa, and then perform an air blowing process on the experimental system without feeding.

...

Embodiment approach 2

[0049] Such as figure 1 As shown, in this implementation example, the conveying pipeline has a diameter of DN125 and a length of 800m as an example. Conduct visual long-distance dense-phase pneumatic conveying experiments.

[0050] The experimental method using the described visualized long-distance dense-phase positive pressure pneumatic conveying test device includes the following steps:

[0051] Step 1: Before the experiment, set the conveying pipeline 25 to a diameter of DN125 and a length of 800m; adjust one Ф8mm air intake hole and some 26 Ф3mm air intake holes of the porous orifice throttling device 10 to open to obtain a stable air volume Flow rate, check the running status of the air compressor and the tightness of the air storage tank and various valves.

[0052] Step 2: Start the air compressor to compress the air so that the pressure in the air storage tank reaches above 0.5MPa, and then perform an air blowing process on the experimental system without feeding. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com