Automatic charging machine and control method of glass microfiber kiln

A glass microfiber and automatic feeding technology, which is used in the feeding of melting furnaces, glass manufacturing equipment, manufacturing tools, etc. The effect of surface stability and improvement of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

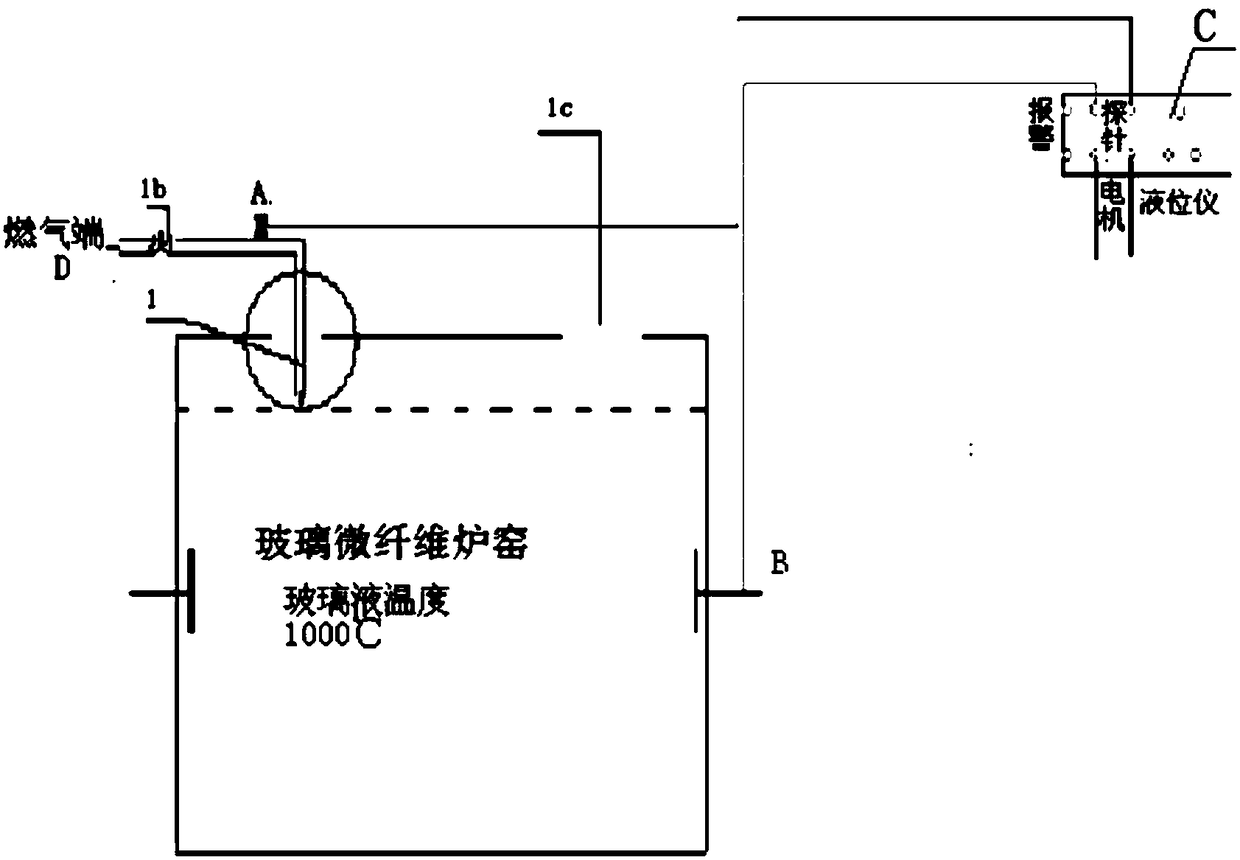

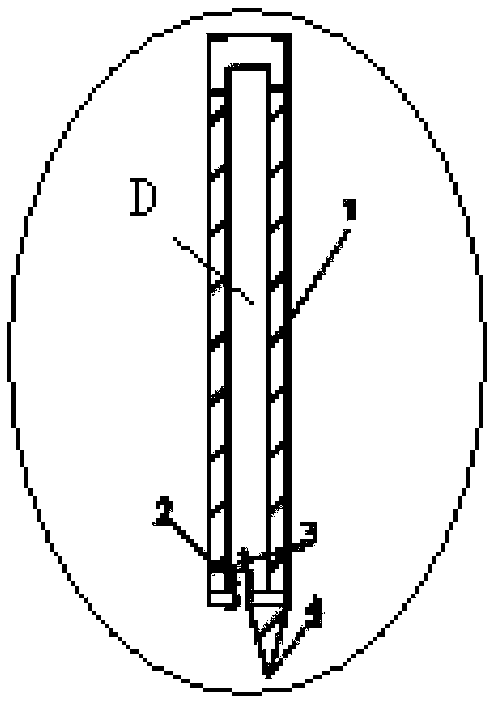

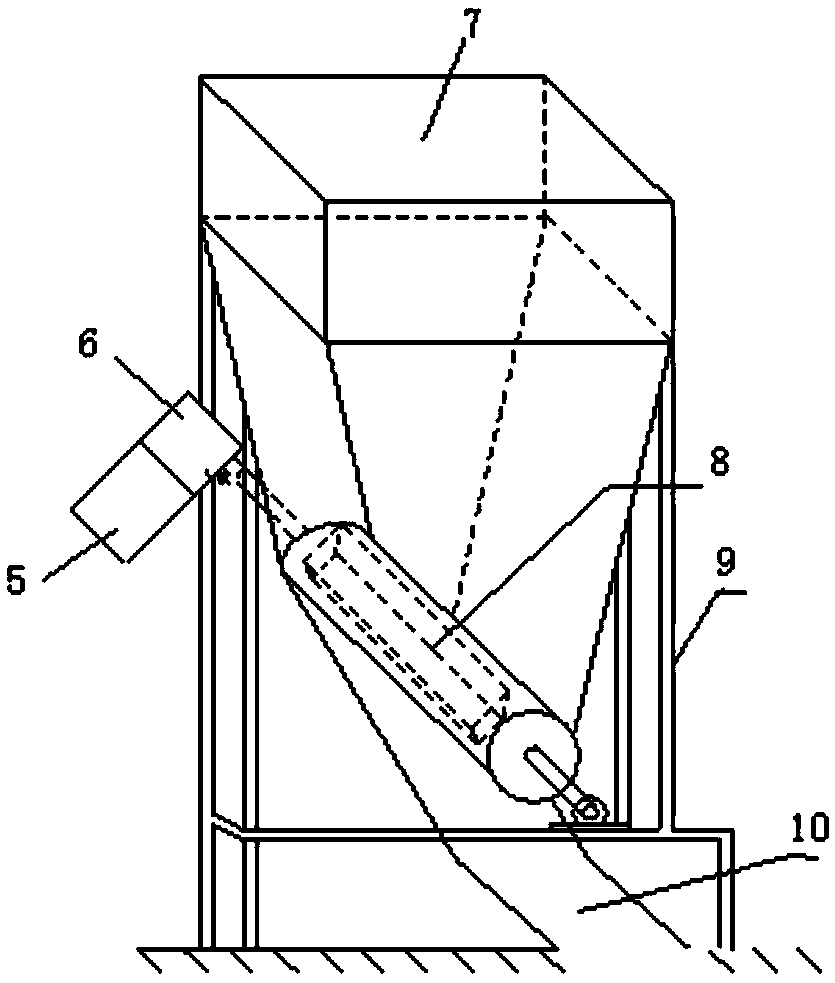

[0021] The automatic feeding control method of the glass microfiber kiln of the present invention is suitable for the production of glass microfibers with high content of silicon, aluminum and barium in the glass raw material components and low solidification point, and is characterized in that it solves the problem of liquid level gauge. The method for the problem of adhesion between the needle end and the liquid surface is: heat the front end of the probe, the temperature of the glass melt is 1180-1200°C, when the kiln temperature environment is 1000°C, heat the probe end: turn on the gas switch 1b, Adjust the air supply volume, deliver gas d to the probe gas nozzle 3 through the gas pipeline D and the probe tube, and heat the front end of the probe to 1030-1050°C with a continuous flame, so that the temperature around the probe point 4 is higher than that of the molten material The temperature of the liquid level is 30-50°C, so that the liquid flow properties of the molten m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com